Alignment agent and liquid crystalline polyimide used therein

A technology of polyimide and alignment agent, which is applied in liquid crystal materials, nonlinear optics, instruments, etc., and can solve problems such as increasing light irradiation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

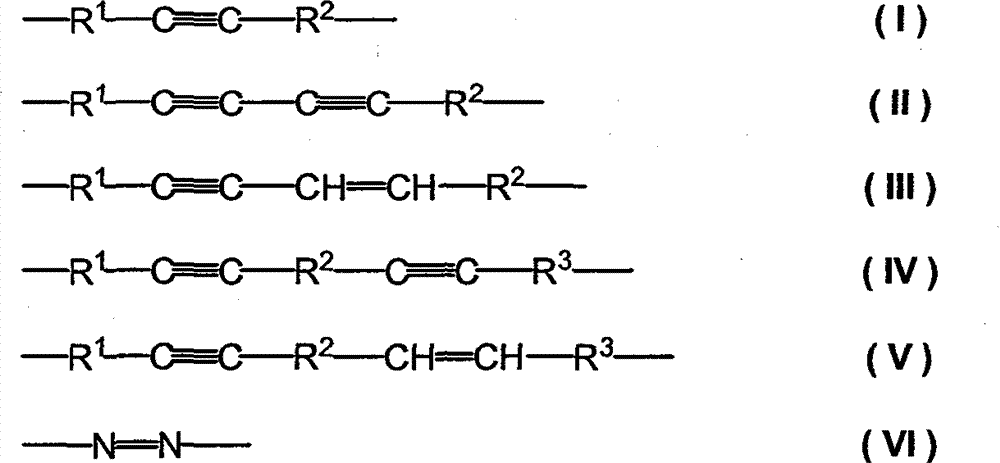

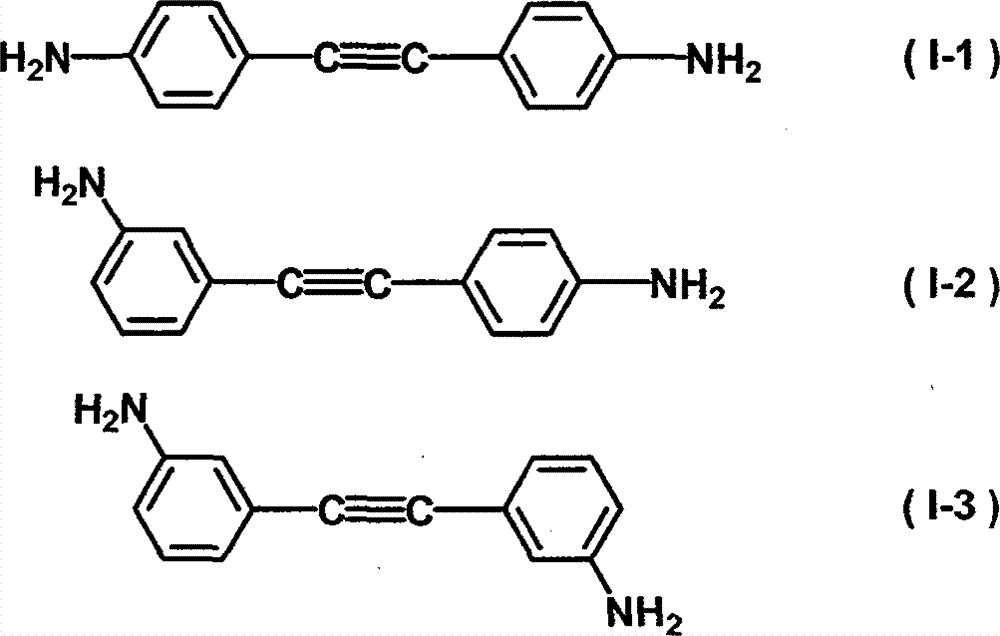

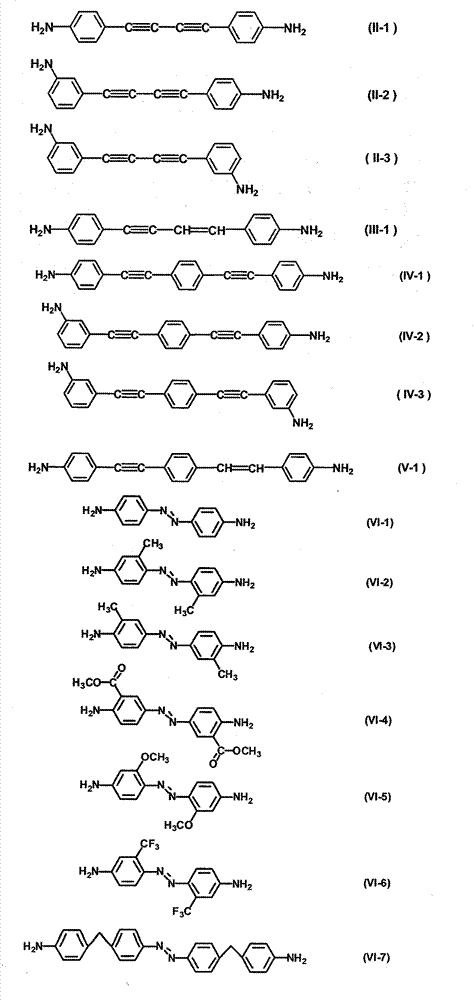

Method used

Image

Examples

Embodiment

[0257] Hereinafter, although an Example and a comparative example demonstrate this invention, this invention is not limited to these Examples. Pyromellitic anhydride (PMDA, compound (A-1)), 1,2,3,4-cyclobutane tetracarboxylic acid (1,2,3,4-cyclobutanet racarboxylic acid, CBTA, compound (A-14)) and compound (2-13) were used in experiments after purification of commercially available compounds by recrystallization. 1,8-Diaminooctane (1,8-Diaminooctane, DAO, compound (VII-1-1)) was used after distilling a commercial product. Compound (II-1) and compound (A-21) were synthesized according to JP-A-5-65530 and JP-A-58-109479, respectively. The following compound (VII-2-1), compound (VII-2-2), and compound (VII-5-1) are based on Japanese Patent Application Laid-Open No. 11-160712 and Bulletin de la Societe Chimique de France, 9-10, Pr.2, the method disclosed in 2195 (1975) and synthesized. Compound (VIII-5) and Compound (VIII-6) were used in experiments without purification of comm...

Synthetic example 1

[0282]

[0283]

[0284] Synthesis was carried out in the same manner as the compound of (VII-2-2). Melting point: 98.0℃~99.2℃.

Synthetic example 2

[0286]

[0287]

[0288]Diethyl 4-bromophthalate (50g, 166mmol), 1,7-octadiyne (8.7g, 82mmol), triphenylphosphinepalladium(II) chloride (290mg, 0.41mmol), and A mixture of copper iodide (158 mmol, 0.83 mmol) was refluxed in triethylamine (200 mL) for 4 hours under nitrogen flow. After the reaction was completed, toluene (500 ml) and pure water (500 ml) were added for extraction. The organic layer was washed once with pure water (300 ml), and then dried over anhydrous magnesium sulfate. Filtration was performed, and the solvent was distilled off under reduced pressure to obtain the target 1,4-bis(3,4-dicarboxyphenyl)ethynylbutane tetraethyl ester. Yield 42 g, 95% yield. This compound was used directly in the next reaction without purification.

[0289] In 1,4-bis(3,4-dicarboxyphenyl)ethynylbutane tetraethyl ester (42g, 77mmol), add 5wt% palladium carbon catalyst (Pd / C) (2.1g), then in toluene / Hydrogenation was carried out at a hydrogen pressure of 720 MPa in an ethano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com