Low-viscosity polyolefin synthetic lubricating oil and preparation method thereof

A technology for synthesizing lubricating oil and polyolefin, which can be used in the production of lubricating compositions, liquid hydrocarbon mixtures, petroleum industry, etc., can solve problems such as insufficiency, and achieve the effect of good viscosity-temperature characteristics and low-temperature flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

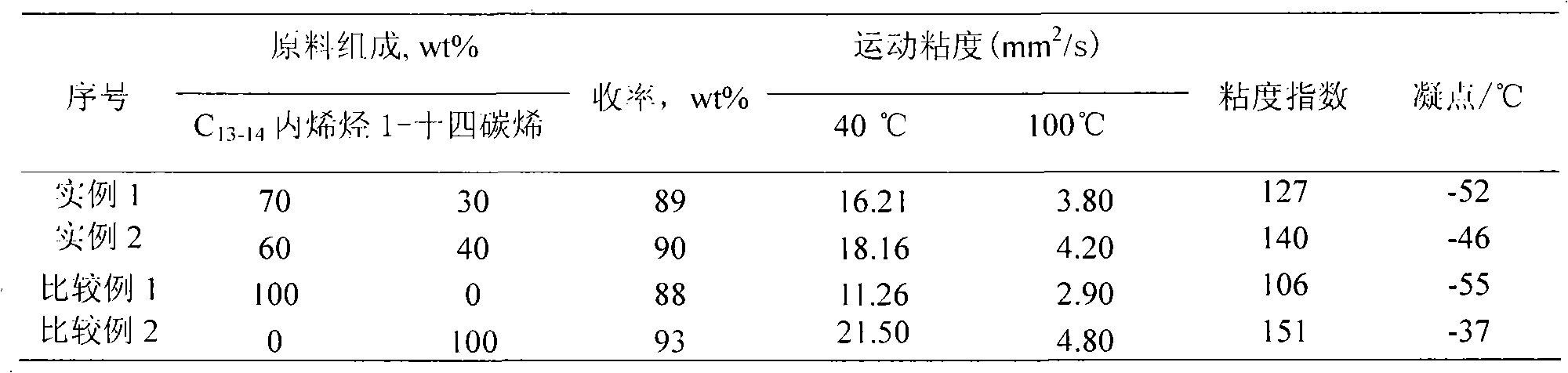

[0013] Add 35g (46ml) of C to a 100ml dry miniature reactor 13 ~C 14 Internal olefin mixture and 15g (20ml) of 1-tetradecene, add 0.2g (0.25ml) of n-butanol, use a constant temperature water bath to heat, control the reaction temperature to 80 ° C, and then pass into BF 3 (excessive), the reaction pressure was controlled at 0.4MPa, and the reaction was carried out for 4h. After the reaction, the product was transferred into a separatory funnel, neutralized with 5% NaOH solution, washed with water until neutral, settled at room temperature, separated after all the water was precipitated, and distilled to remove light components and untreated React monomers to obtain polyolefin synthetic oil. Synthetic oils can subsequently be hydrogenated to improve thermal and oxidative stability. The evaluation data are listed in Table 1.

example 2

[0015] In addition to adding 30g (40ml) of C to a 100ml dry microreactor 13 ~C 14 The internal olefin mixture and 20 g (26 ml) of 1-tetradecene are the same as in Example 1. The evaluation data are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com