Ti-Hf-Si-Al-C, Ti-Hf-Al-C and Ti-Zr-Al-C solid solution material and preparation method thereof

A solid solution, titanium-zirconium-aluminum technology, which is applied in the field of ceramic solid solution materials and preparation, can solve the problems of rigidity, strength and other mechanical properties decline and limit wide application, and achieve the effects of shortening chemical reaction time, simple process and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

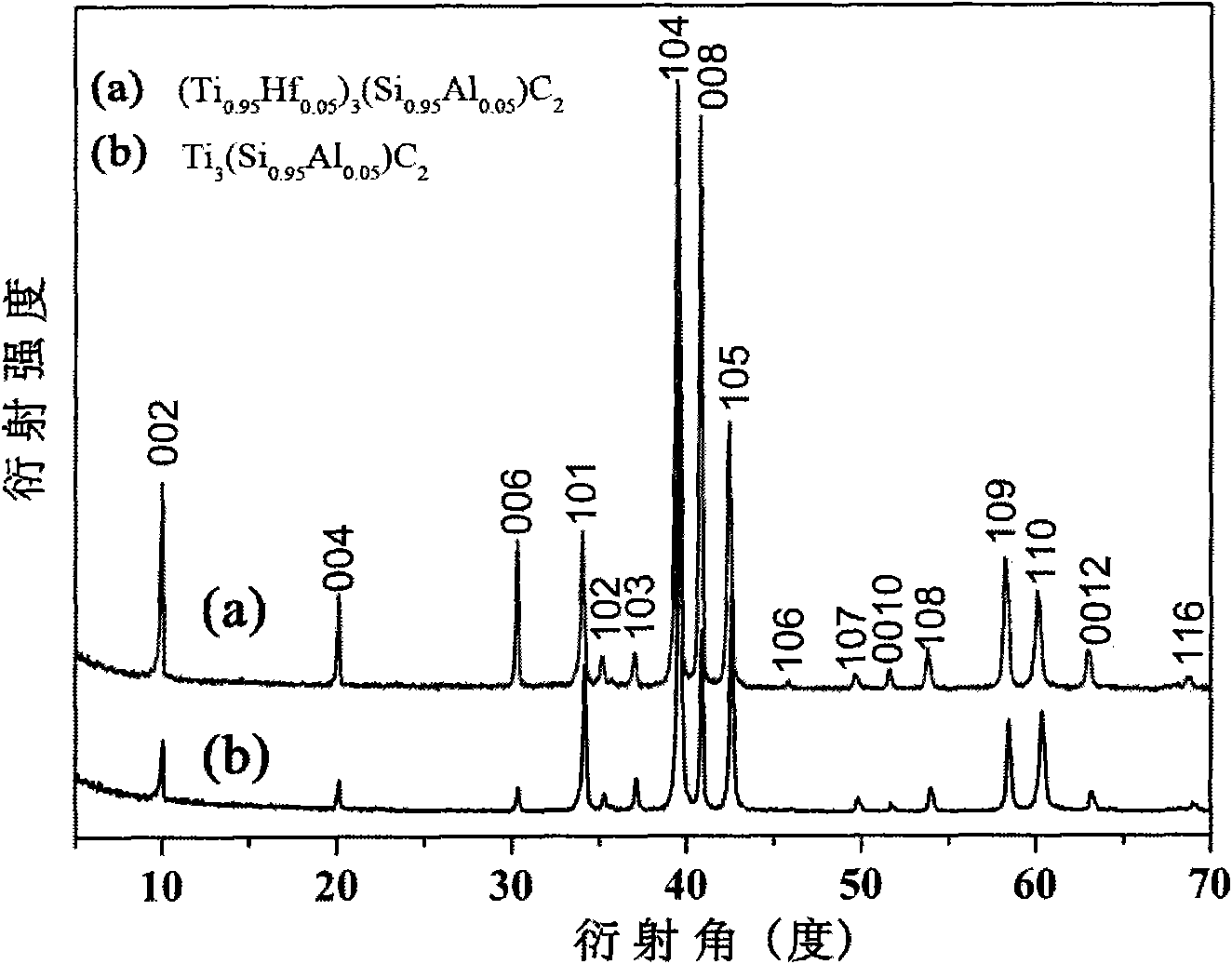

[0027] The particle size range of 200-400 mesh titanium powder 30.59 grams, hafnium powder 5.94 grams, silicon powder 7.01 grams, aluminum powder 0.30 grams and graphite 5.50 grams (stoichiometric ratio of (Ti 0.95 Hf 0.05 ) 3 (Si 0.95 Al 0.05 )C 2 ) Ball milled in alcohol medium for 10 hours, then placed in a graphite mold for cold pressing, the applied pressure is 5MPa, and the cold pressing time is 15 minutes; put it into a hot pressing furnace for hot pressing and sintering at a heating rate of 10°C / min, heating Keep the temperature at 1580°C for 1 hour while gradually increasing the pressure to 25MPa. Then the temperature was lowered to 1400°C, and the temperature was kept at 1400°C for 0.5 hours. The pressure during the whole heat preservation process was maintained at 25MPa. The entire sintering process is carried out under the protection of argon, and the obtained reaction product is analyzed by X-ray diffraction as (Ti 0.95 Hf 0.05 ) 3 (Si 0.95 Al 0.05 )C 2 ( figure 1 (...

Embodiment 2

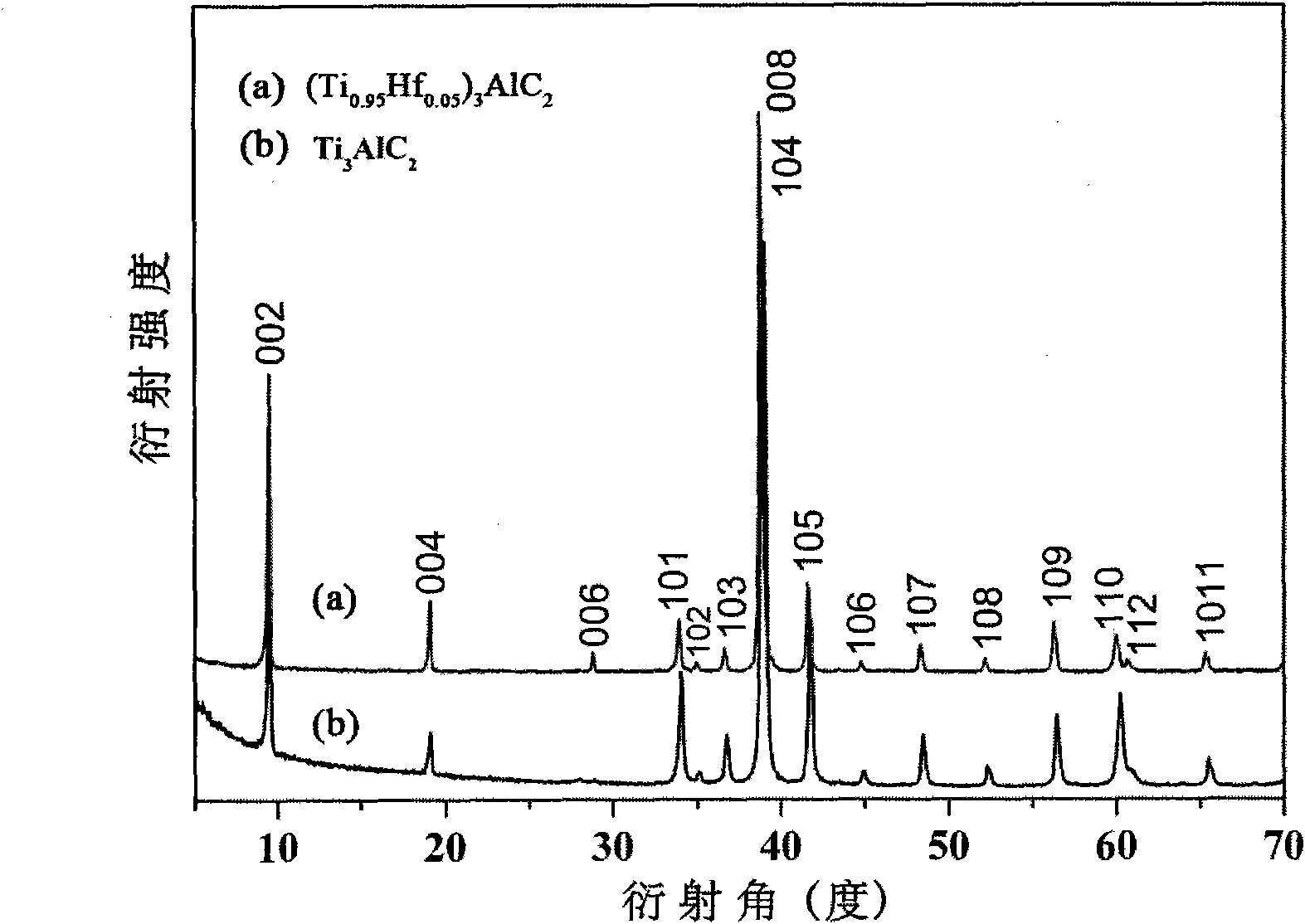

[0029] The particle size range of 200-400 mesh titanium powder 50.98 grams, hafnium powder 10.10 grams, aluminum powder 10.50 grams and 8.50 grams of graphite (stoichiometric ratio is (Ti 0.95 Hf 0.05 ) 3 AlC 2 ) Ball milled in alcohol medium for 15 hours, then placed in a graphite mold for cold pressing, the applied pressure is 5 MPa, and the cold pressing time is 20 minutes; put it in a hot pressing furnace for hot pressing and sintering at a heating rate of 15°C / min, heating Keep the temperature at 1530°C for 1 hour while gradually increasing the pressure to 30MPa. Then the temperature was reduced to 1400°C, and the temperature was kept at 1400°C for 0.5 hours. The pressure during the whole heat preservation process was maintained at 30MPa. The entire sintering process is carried out under the protection of argon, and the obtained reaction product is analyzed by X-ray diffraction as (Ti 0.95 Hf 0.05 ) 3 AlC 2 ( figure 2 (a)). (Ti 0.95 Hf 0.05 ) 3 AlC 2 The Vickers hardness ...

Embodiment 3

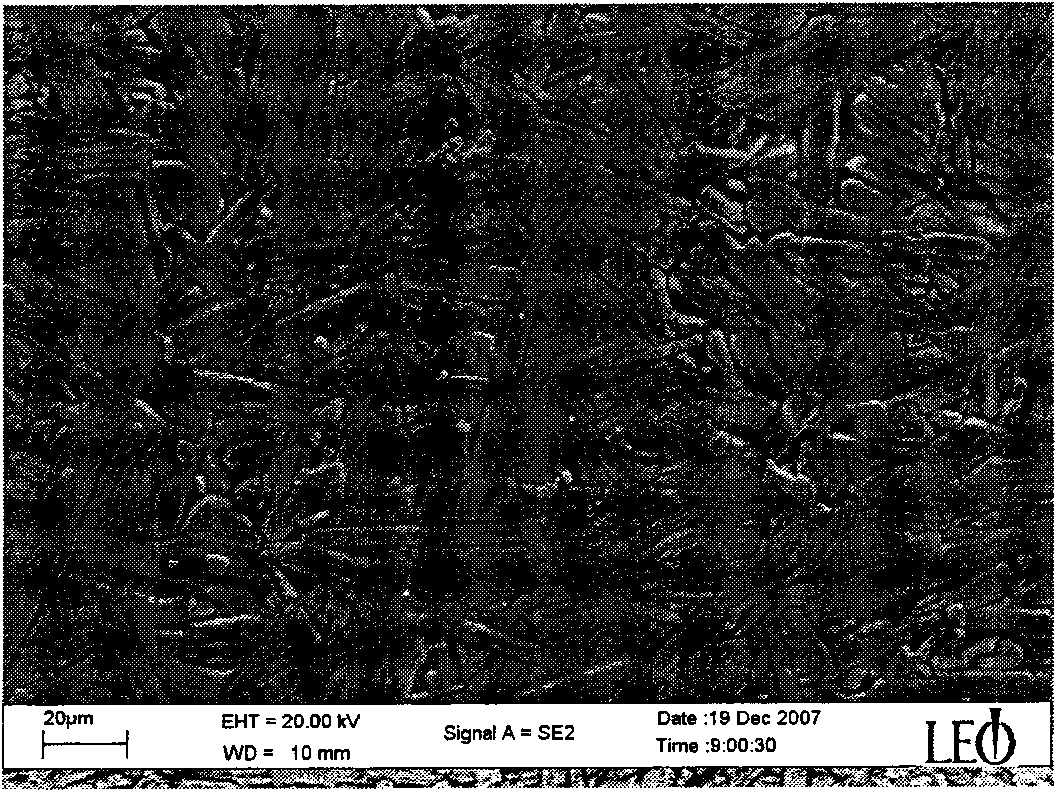

[0031] The particle size range is 200-400 mesh titanium powder 89.79g, zirconium powder 9.10g, aluminum powder 18.63g and graphite 15.12g (stoichiometric ratio is (Ti 0.95 Zr 0.05 ) 3 AlC 2 ) Ball milled in an alcohol medium for 20 hours, then put into a graphite mold for cold pressing, the applied pressure is 15 MPa, and the cold pressing time is 5 minutes; put it into a hot pressing furnace for hot pressing and sintering at a heating rate of 10°C / min, heating Keep the temperature at 1550°C for 1 hour while gradually increasing the pressure to 35MPa. Then the temperature was lowered to 1400°C, and the temperature was kept at 1400°C for 0.5 hours. The pressure during the whole heat preservation process was maintained at 35MPa. The whole sintering process is carried out under the protection of argon, and the reaction product obtained is composed of lath grains (Ti 0.95 Zr 0.05 ) 3 AlC 2 ( image 3 ). (Ti 0.95 Zr 0.05 ) 3 AlC 2 The Vickers hardness of the solid solution material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com