Rail pressure generation module and system integration technology

A technology of pressure power generation and system integration, which is applied to generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, collectors, etc., can solve the problems of difficult storage, large volume, and huge energy consumption. Achieve the effect of low price, reduce noise and slow down the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

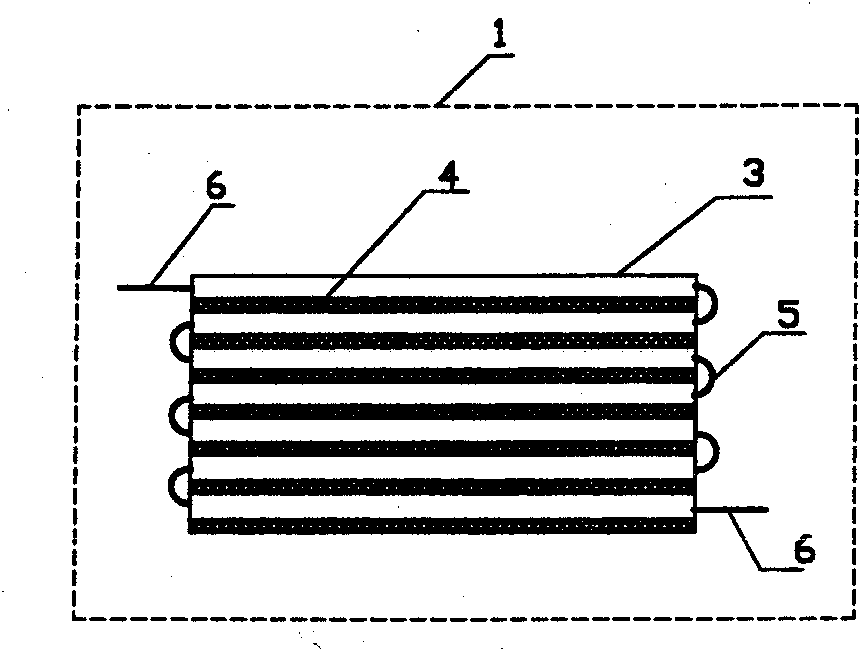

[0045] figure 1 In this method, multiple layers of piezoelectric materials (3) are stacked together, and there are isolation layers (4) between the layers, and the layers are connected by connecting wires (5) and drawn out by lead wires (6). , they are combined into a power generation module (1).

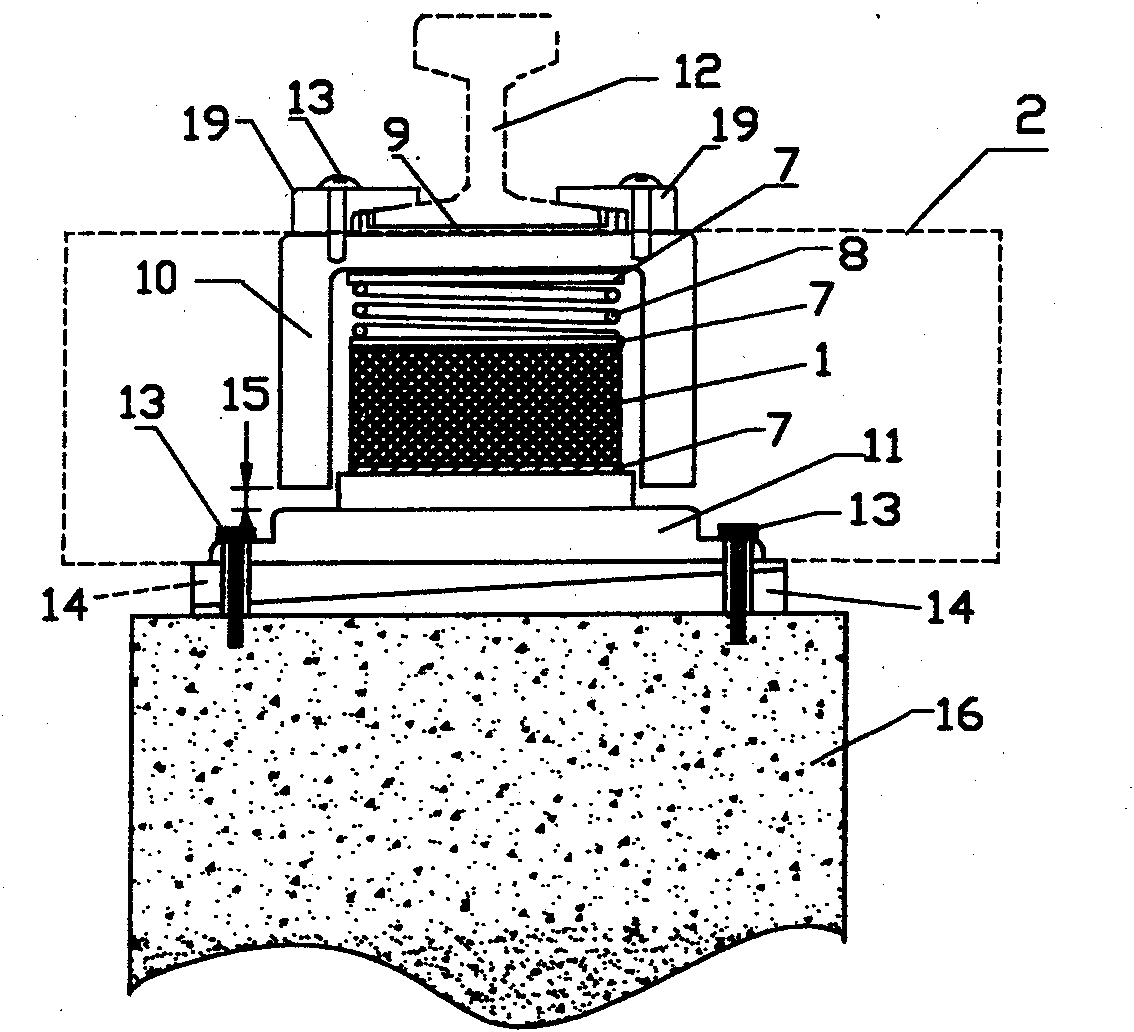

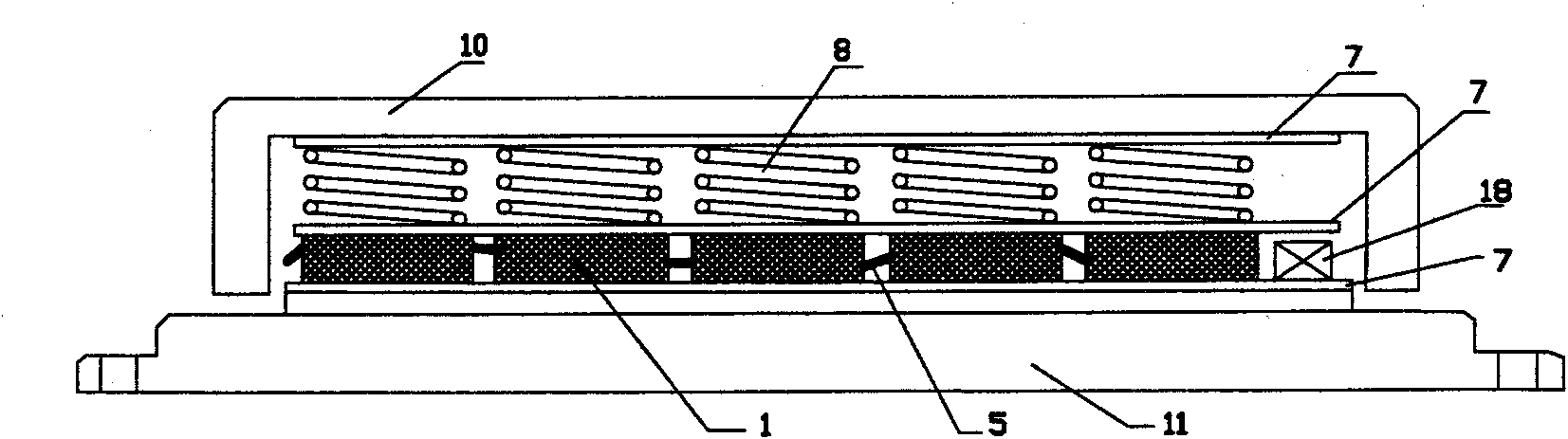

[0046] figure 2 Among them, the power generation module (1) is installed between the two lower splints (7), a damping spring (8) is installed between the middle splint and the upper splint (7), and the bottom splint (7) is fixed On the base (11), the last upper shell (10) covers the entire power generation module, springs, protection, and display circuits to prevent rain from penetrating into the shell,

[0047] The upper casing (10) covers the base (11), and there is a limit gap (15) between the base (11). Generally, the train will not close the gap under normal pressure. Only when the train pressure is abnormal or sudden This gap is only closed when the pressure is over, so as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com