Multi-station welding device and method for auto expansion valve

An expansion valve, multi-station technology, used in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting precision components, low welding quality, incomplete welding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

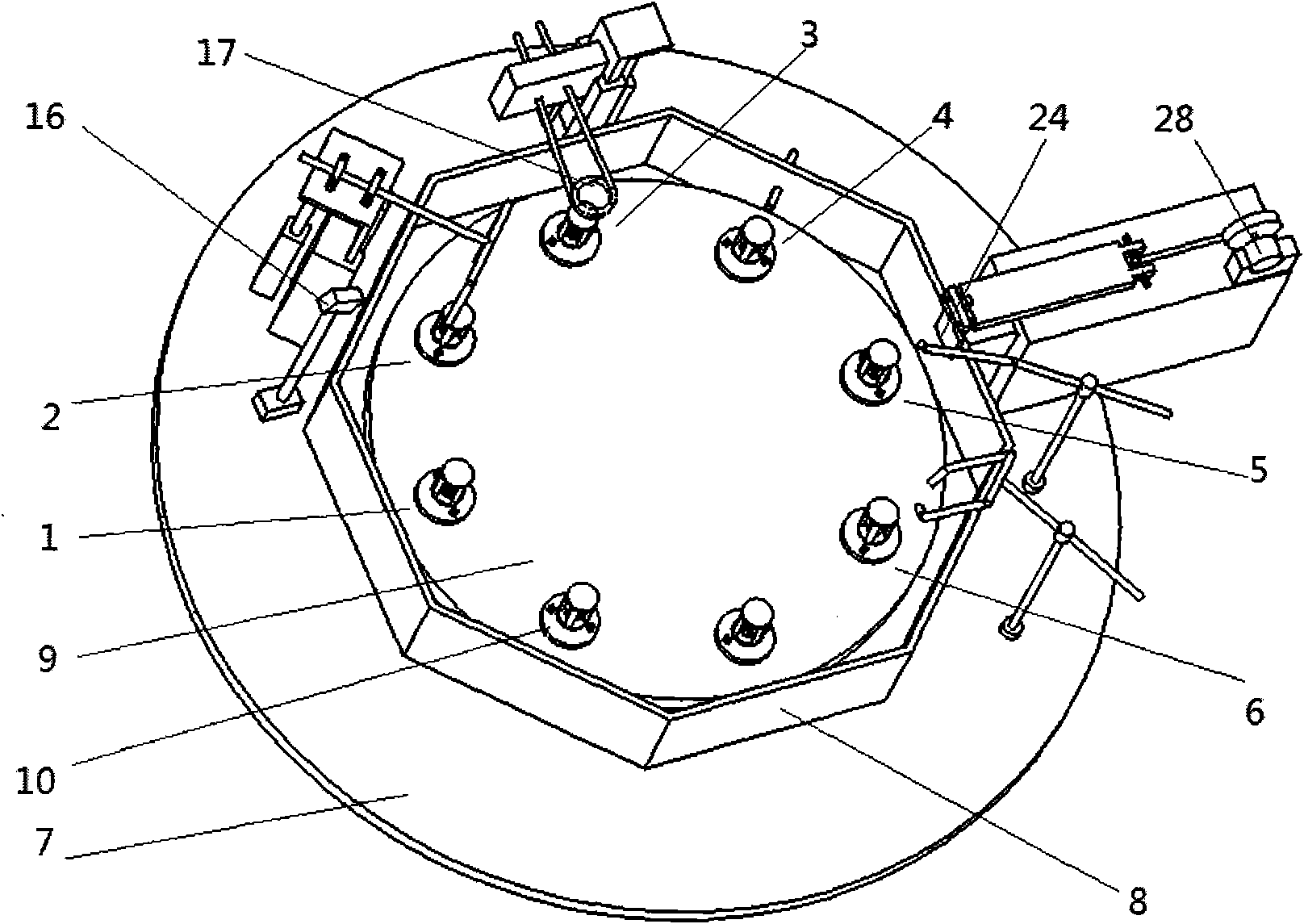

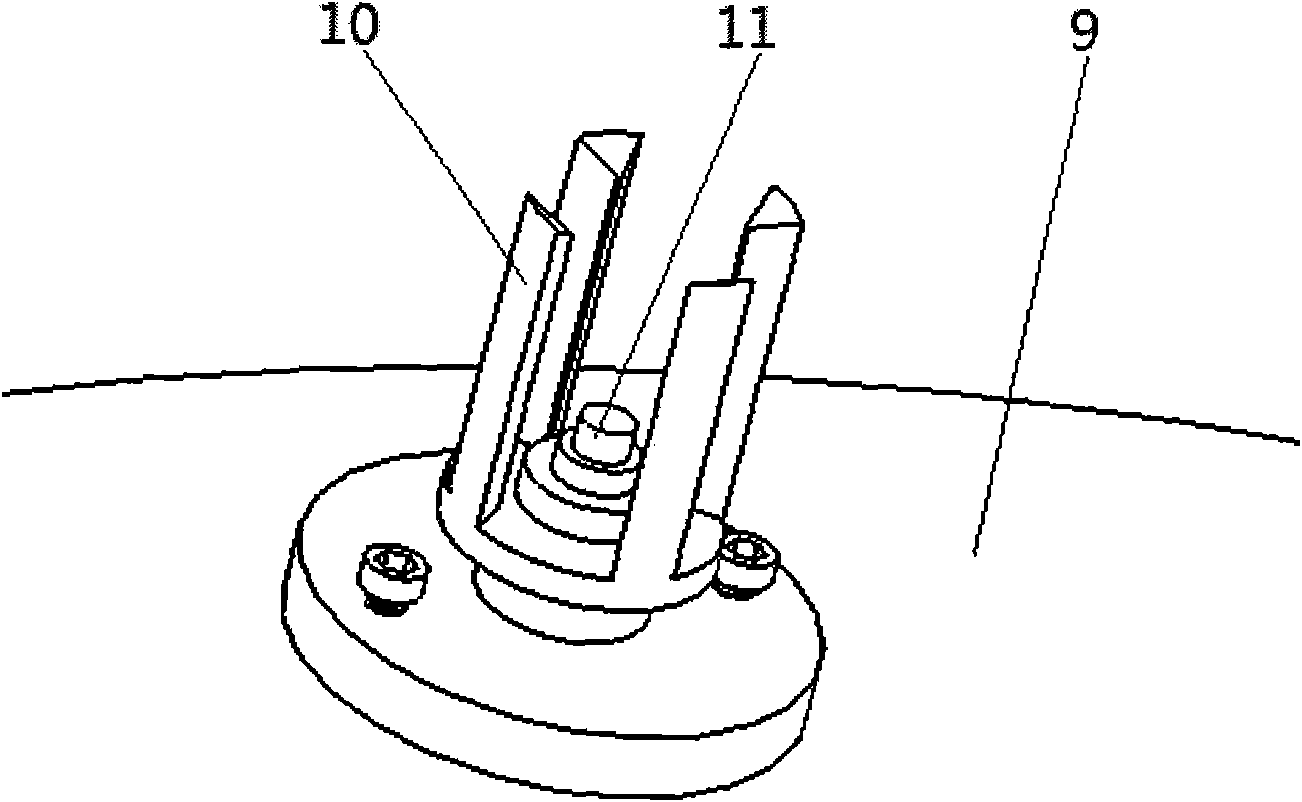

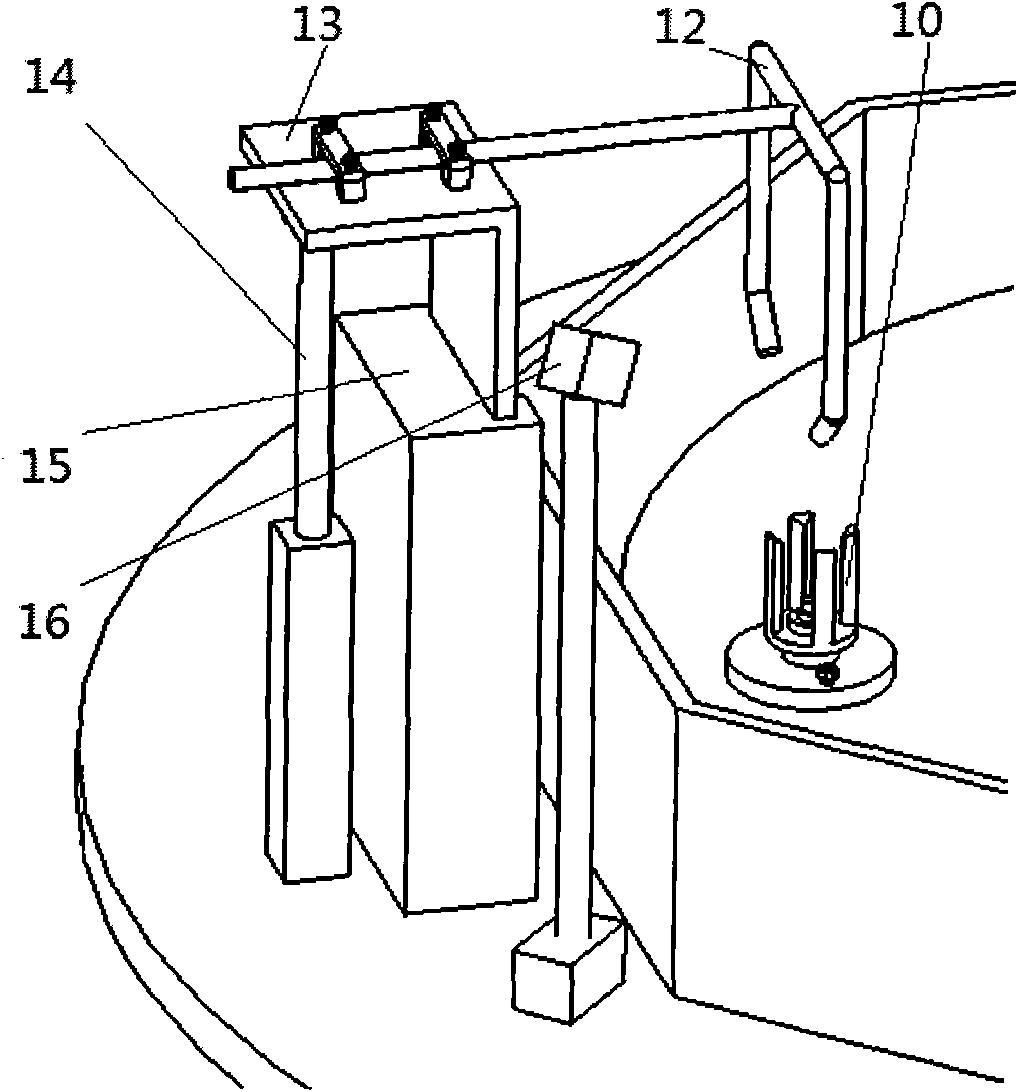

[0025] Such as figure 1As shown, the multi-station welding device of the automobile expansion valve includes a preparation station 1, a preheating station 2, a high-frequency heating station 3, a water cooling station 4, a cleaning station 5, a water washing station 6, a working table 7, Baffle plate 8, station turntable 9, workpiece support 10, workpiece plug nozzle 11, flame heating tube 12, flame heating tube lifting platform 13, preheating station cylinder 14, flame heating tube lifting bracket 15, infrared sensor 16, high High-frequency heating tube 17, high-frequency heating tube lifting platform 18, high-frequency heating tube lifting bracket 19, high-frequency heating station cylinder 20, water-cooling water pipe 21, cleaning water pipe 22, brush fixing piece 23, brush 24, cleaning water pipe fixing frame 25 , slide plate 26, connecting rod 27, slide plate driving motor 28, motor turntable 29, motor fixing frame 30, cleaning station fixing frame 31, washing water pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com