Manufacturing process of wind power vanes

A wind power blade and manufacturing process technology, which is applied in wind power generation, sustainable manufacturing/processing, wind turbines, etc., can solve the problems of difficult product quality control, low product mechanical properties, waste of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

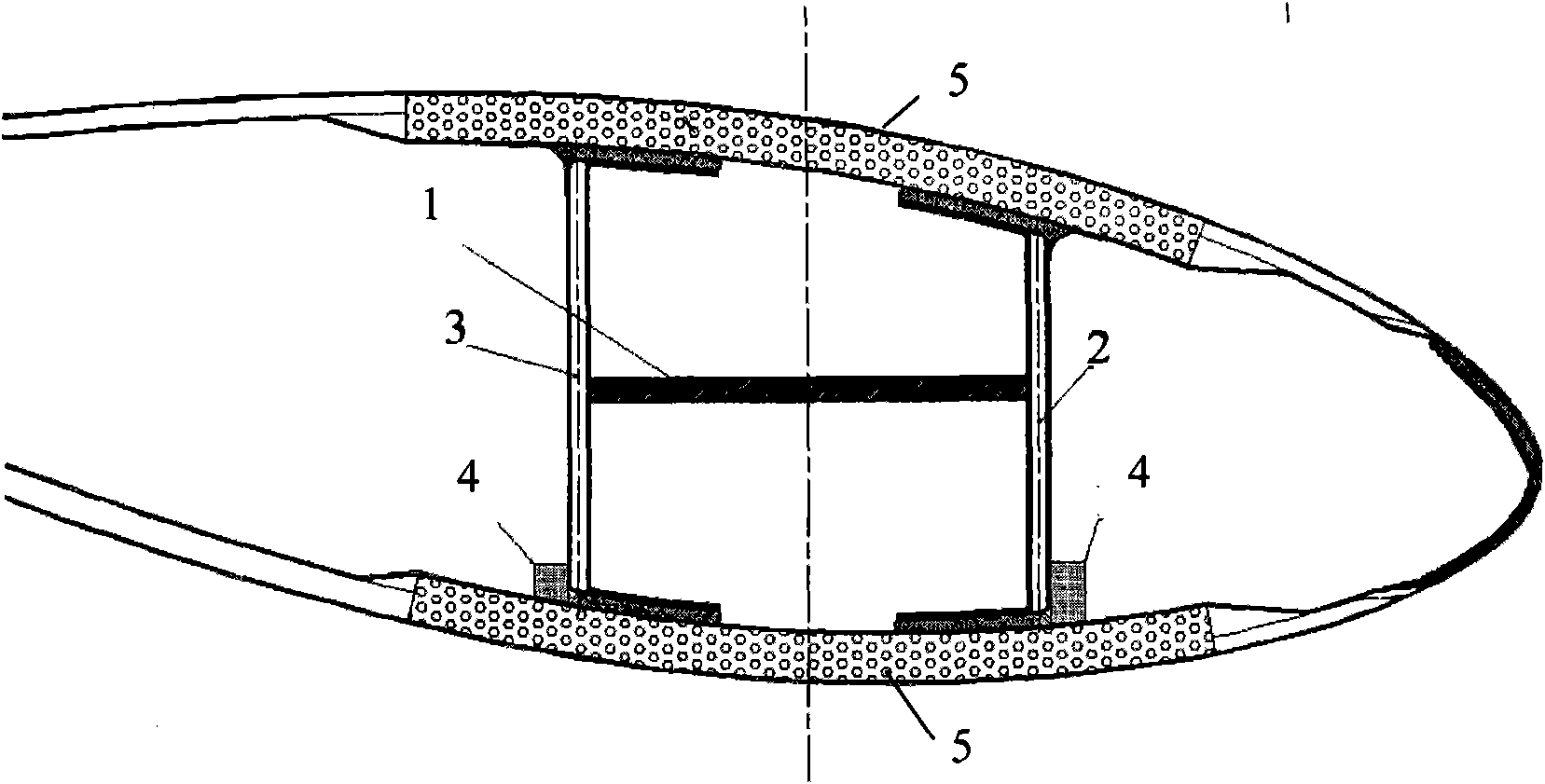

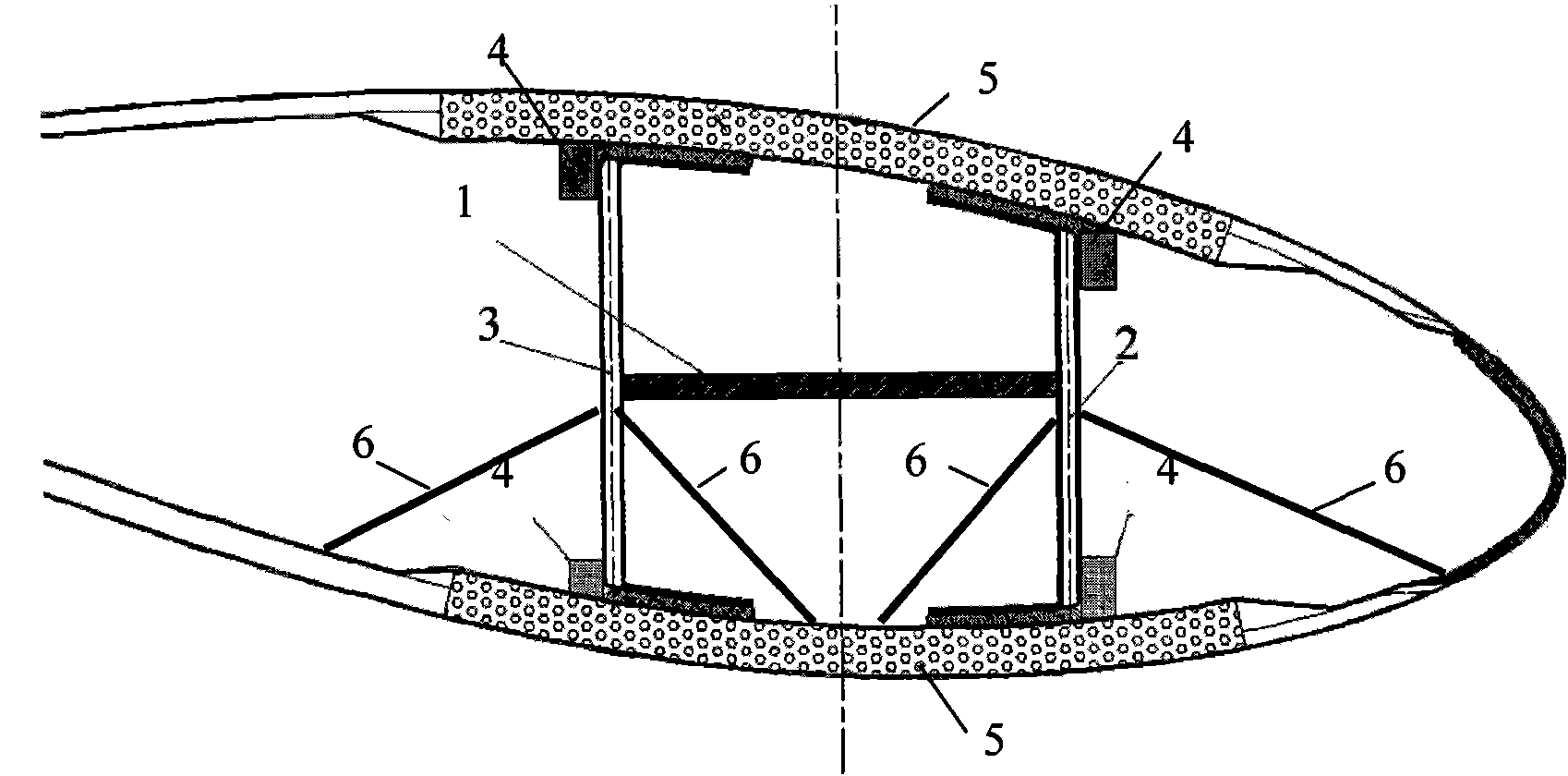

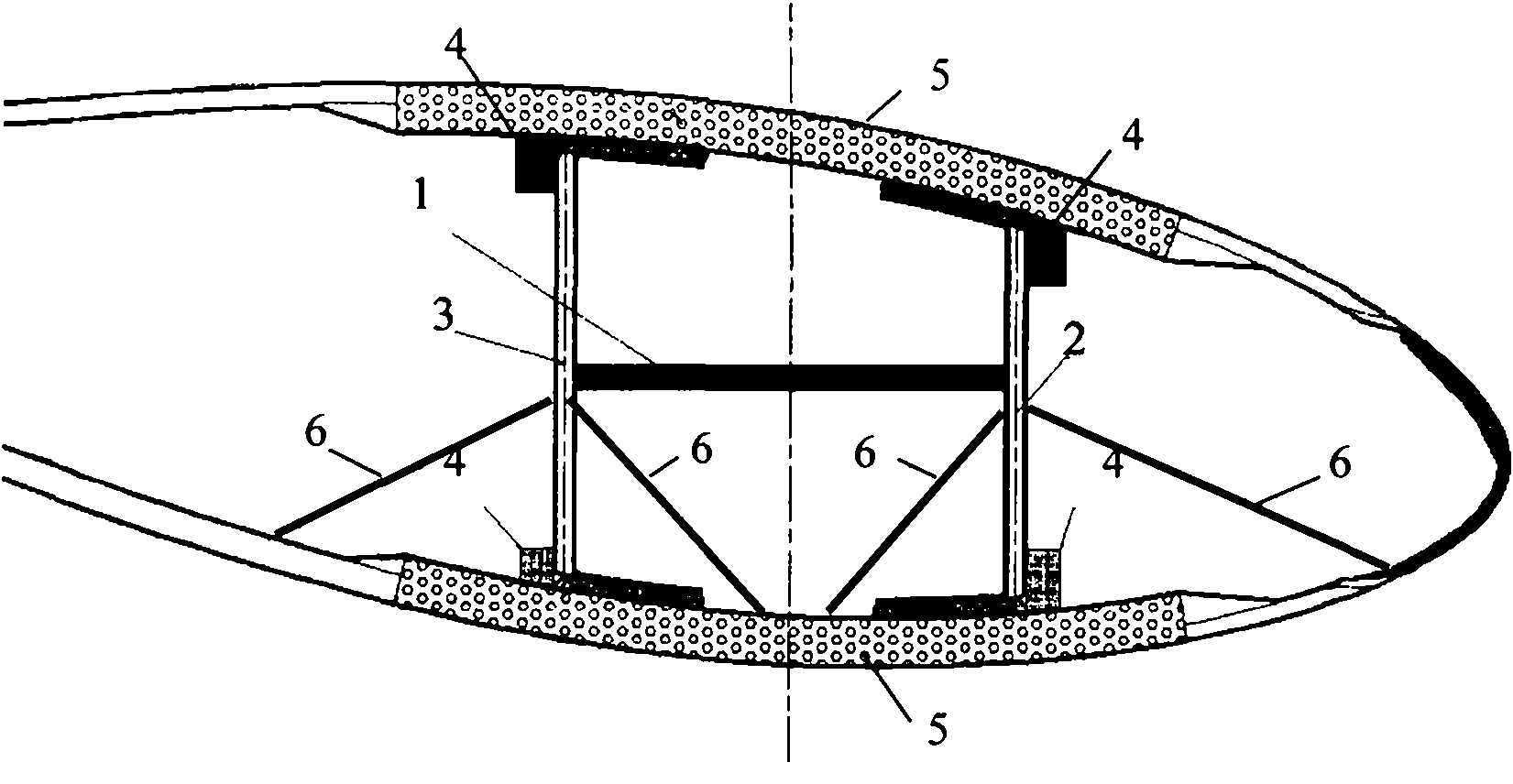

[0020] figure 1 The main structure of the wind turbine blade according to an embodiment of the present invention is shown in a cross-sectional view, in which 1 is the connecting block of the main bracket, 2 and 3 are the front and rear main brackets, 4 is the positioning block, and 5 is the upper and lower shells. The manufacturing process of wind power blades includes the following steps: cutting of reinforcement materials, calculation of matrix material mixing viscosity and gel time, cutting of sandwich materials, preparation of materials required for vacuum introduction, making of upper and lower shells 5 of blades by using molds, and making of blade roots by using molds Platform, use molds to make main brackets 2, 3, assemble the main brackets 2, 3 and install them on the blade lower shell 5, carry out mold closing, and then carry out subsequent processing procedures, wherein the assembled main brackets 2, 3 are used Fix the main brackets 2 and 3 with clamps while bonding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com