Printing and dyeing wastewater decoloring method and system

A printing and dyeing wastewater and decolorization technology, which is applied in chemical instruments and methods, textile industry wastewater treatment, water/sewage multi-stage treatment, etc., can solve the problem of large dosage of coagulation decolorization method, expensive activated carbon adsorption method, and oxidant dosage of oxidation method Large and other problems, to achieve the effect of reducing treatment facilities, good decolorization effect, and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

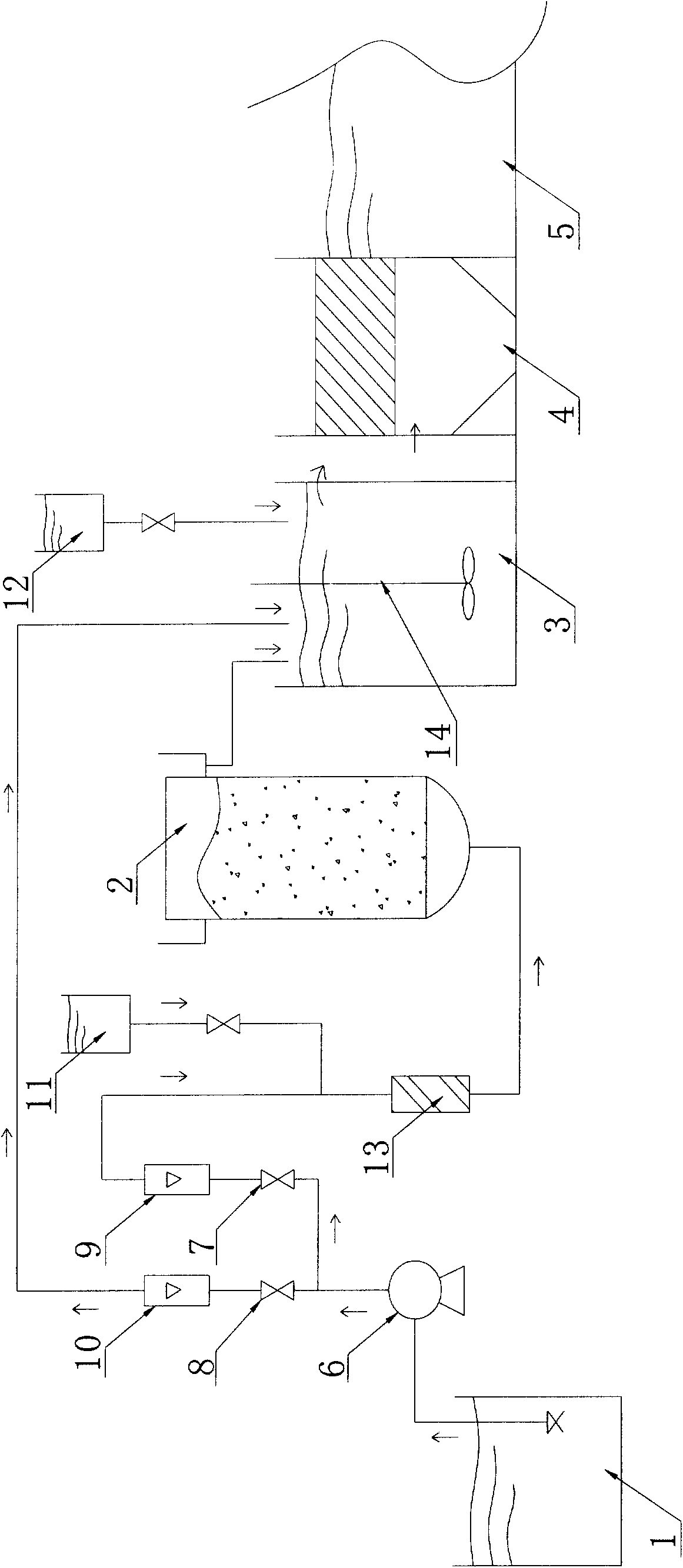

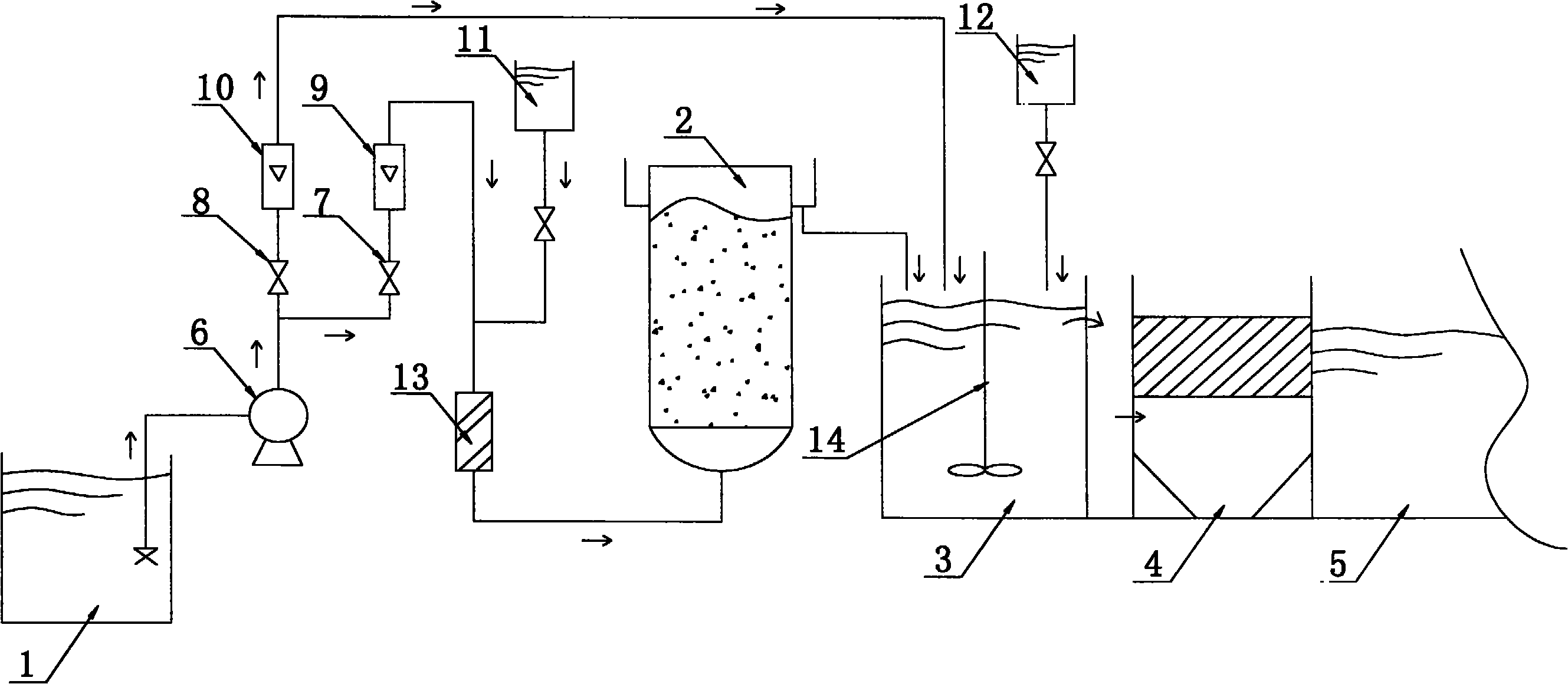

[0036] Such as figure 1 Shown: the printing and dyeing wastewater with high chroma and high alkalinity (chroma 820, COD=680mg / L, PH≈12.5) in the wastewater regulating tank 1 is lifted and shunted through the lift pump 6, so that 1 / 3 of the wastewater passes through the diverter valve 7 and flow meter 9 enter pipeline mixer 13 again, and the waste water is mixed with the acid added in the acid tank 11 so that the pH is adjusted to about 2 and enters the internal electrolytic processor 2. This part of wastewater is treated in the processor 2 and the decolorized wastewater enters the mixed decolorization tank 3 . 2 / 3 of the untreated water extracted by the waste water lifting pump 6 directly enters the mixing decolorization tank 3 through the diverter valve 8 and the flow meter 10, and the two kinds of water are mixed and fully mixed by the agitator 14, and adjusted by the alkali phase in the alkali mixing tank 12 The pH is kept at 9.0, and the waste water is decolorized. The d...

Embodiment 2

[0038] For the decolorization treatment of medium chroma alkaline printing and dyeing wastewater (such as chroma is 350, COD is 420mg / L, PH=9.0) the treatment method is the same as above, the difference is that the amount of water treated by internal electrolytic decolorization is generally 1 / of the total water amount 5, and at the same time, because the two kinds of waste water will consume alkali when they mix and react in the mixed decolorization, the pH will decrease, because the alkalinity in the waste water is not too strong, so it is necessary to add some alkali from the alkali tank (lime water is also OK). Keep pH ≥ 8.5. After treatment, the chroma was 15, the COD was reduced to 280mg / L, the pH was 9.0, and the removal rates reached 96% and 33% respectively. The amount of water for internal electrolysis treatment can be determined according to water quality conditions such as concentration, chroma, and pH, and the amount of water taken is small. The PH needs to be lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com