Treatment method of high-concentration fluorine-contained industrial wastewater

An industrial wastewater, high-concentration technology, used in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

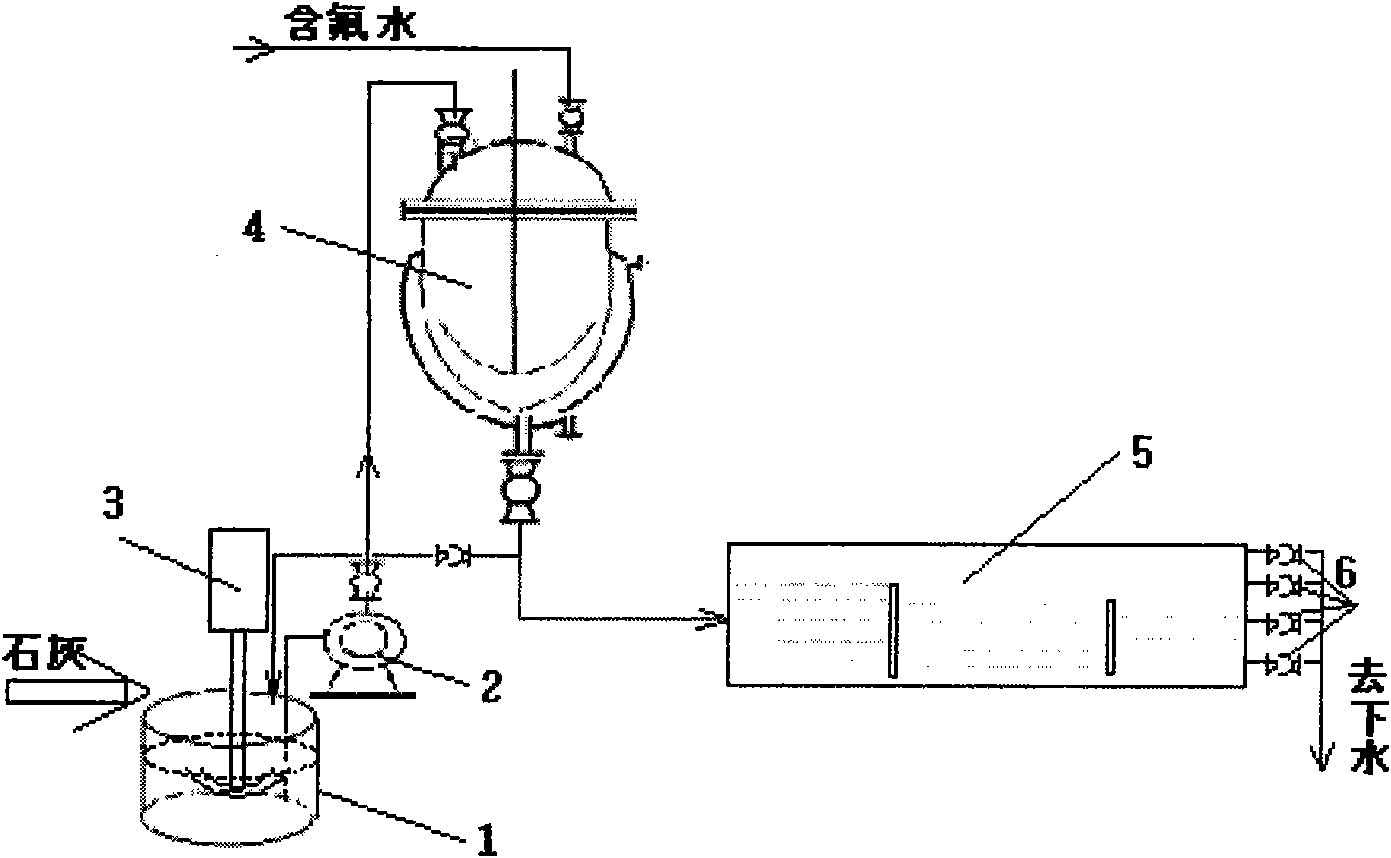

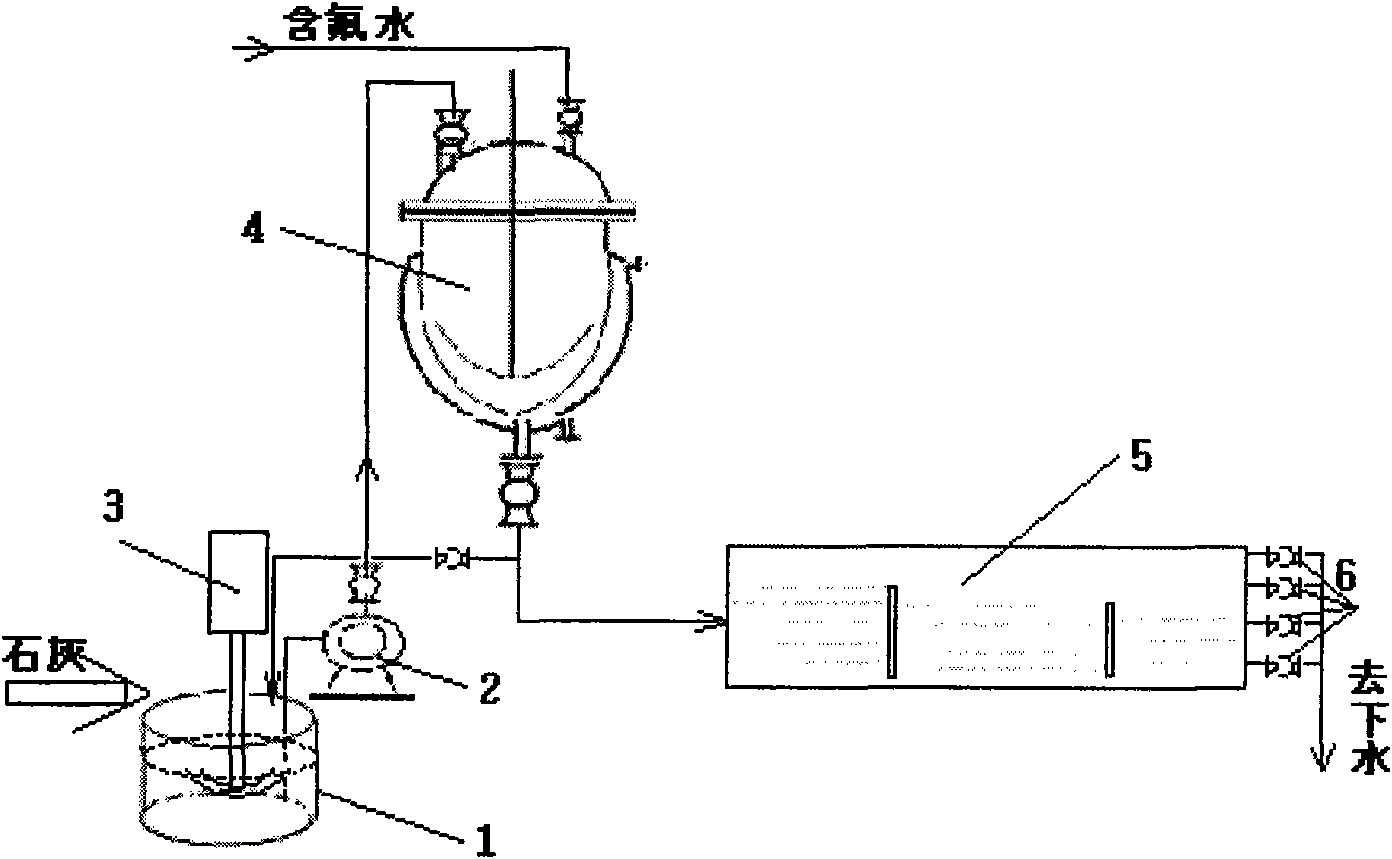

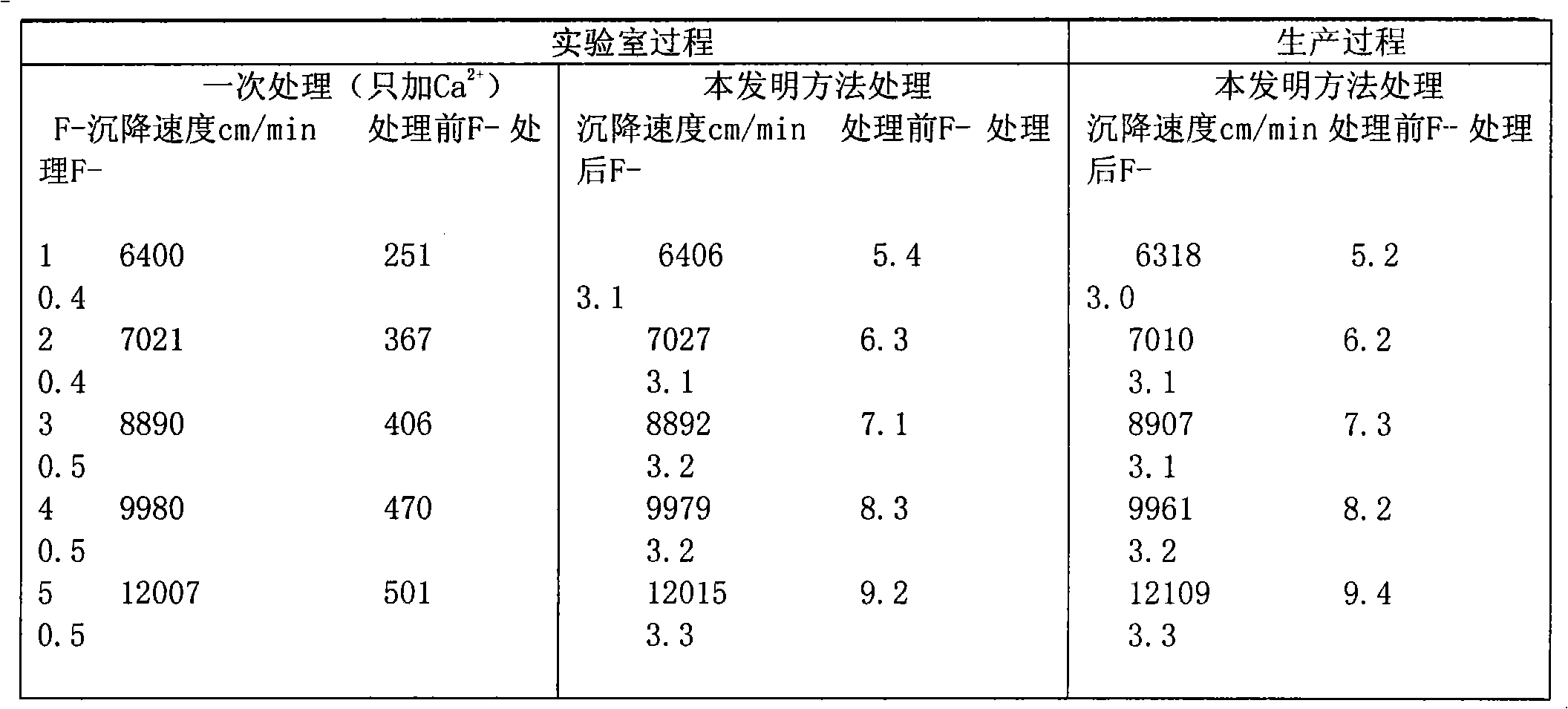

[0015] The following is a detailed description of a treatment method for high-concentration fluorine-containing industrial wastewater according to the accompanying drawings: the wastewater generated by washing the fluoride salt in polyether ketone has a temperature of 90°C, a weight of about 4.0 tons / pot, and a concentration of 6000-10000mg / L. .

[0016] Step one a. at first fluorine-containing waste water is sent in 4.0 tons of reactor 4, as figure 1 As shown, b. then pour 91kg of CaO, 0.21kg of chitosan, and 0.29kg of lignin into the beating tank 1 with a mass percentage of 85%, and c. open the bottom valve of the tank and put fluorine-containing waste water into the beating tank 1 , d. Start the beating motor 3 to stir for three minutes, e. Then start the slurry pump 2 immediately, send all the slurry in the beating tank 1 into the reactor 4, stop the slurry pump 2, f. start the reactor stirring motor to stir 30 minutes;

[0017] Step 2a. Continue to stir in the stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com