Method for producing baked bricks from alumina red mud

A technology for sintering bricks and alumina, applied in the field of sintering bricks, can solve the problems of occupying farmland, polluting the atmosphere, serious environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

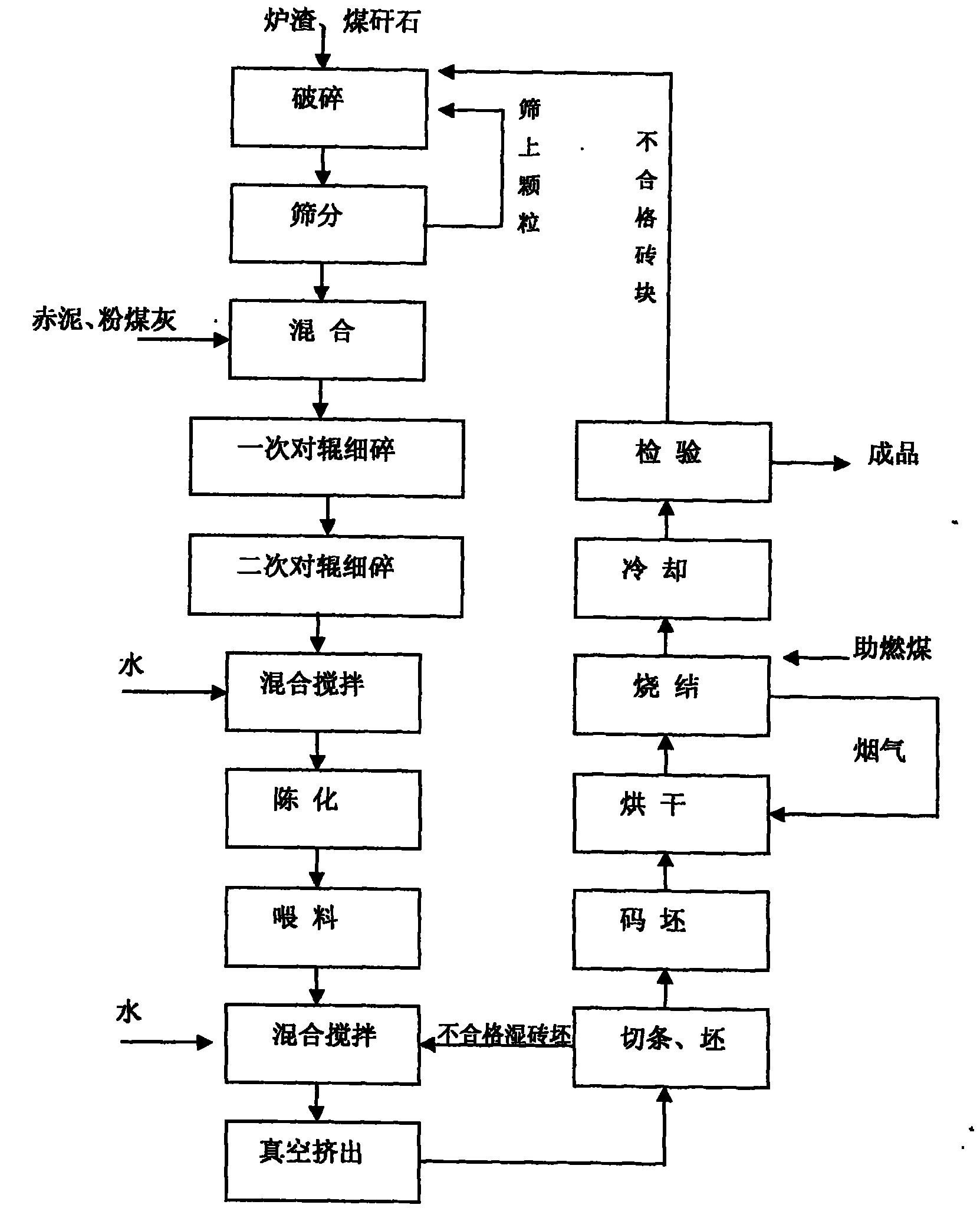

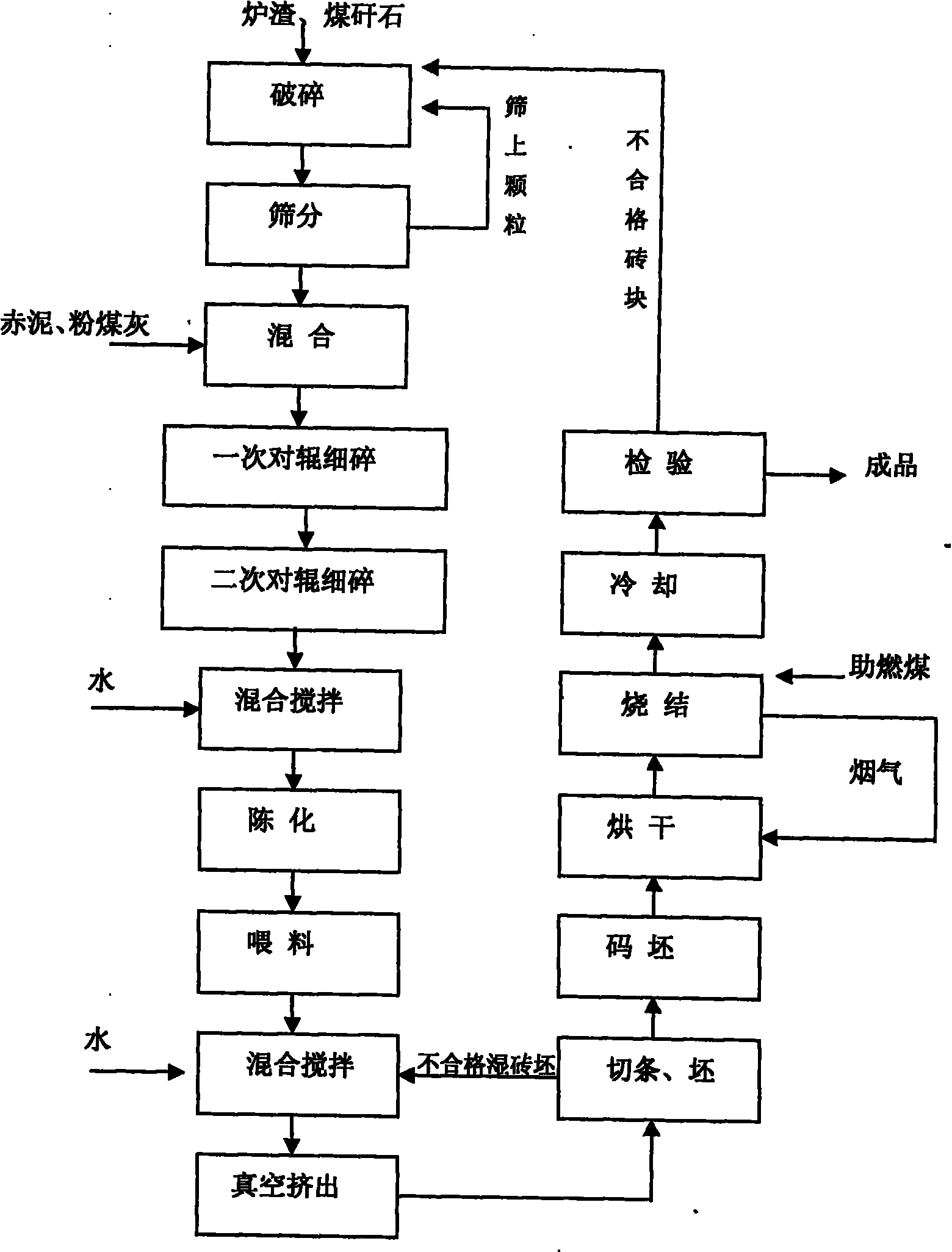

[0023] Embodiment 1: as figure 1 As shown, the method for producing sintered bricks from alumina red mud according to the present invention is prepared from the following raw materials in proportions by weight:

[0024] a. Raw materials: red mud 60; cinder or fly ash 25; coal gangue 15;

[0025] b. Preparation:

[0026] The first step is to crush cinder or fly ash and coal gangue to a particle size of 3mm or less;

[0027] In the second step, the product obtained in the first step is mixed with the red mud, and then input into a roller crusher for fine crushing to a particle size of 3mm or less, and then into a mixer, adding water with a weight of 3% of the material for mixing and stirring;

[0028] The 3rd step, place the result of the 2nd step in the storage tank and carry out shelving and aging for 50 hours;

[0029] The fourth step is to put the aged material in the third step into the mixer, add water with 2% weight of the aged material to mix and stir, then feed it in...

Embodiment 2

[0031] Embodiment 2: as figure 1 As shown, the method for producing sintered bricks from alumina red mud according to the present invention is prepared from the following raw materials in proportions by weight:

[0032] a. Raw materials: red mud 65; cinder or fly ash 22; coal gangue 13;

[0033] b. Preparation:

[0034] The first step is to crush cinder or fly ash and coal gangue to a particle size of 3mm or less;

[0035] In the second step, the product obtained in the first step is mixed with the red mud, and then input into a roller crusher for fine crushing to a particle size of 3 mm or less, and then enters into a mixer, adding water of 2.5% by weight of the material for mixing and stirring;

[0036] The 3rd step, place the result of the 2nd step in the storage tank and carry out shelving and aging for 60 hours;

[0037] The fourth step is to put the aged material in the third step into the mixer, add water with 1.5% weight of the aged material to mix and stir, then fe...

Embodiment 3

[0039] Embodiment 3: as figure 1 As shown, the method for producing sintered bricks from alumina red mud according to the present invention is prepared from the following raw materials in proportions by weight:

[0040] a. Raw materials: red mud 65; cinder or fly ash 20; coal gangue 15;

[0041] b. Preparation:

[0042] The first step is to crush cinder or fly ash and coal gangue to a particle size of 3mm or less;

[0043] The second step is to mix the product obtained in the first step with the red mud and input it into a roller crusher for fine crushing to a particle size of 3 mm or less, then enter the mixer, add 2-3% water of the material weight for mixing and stirring;

[0044] The 3rd step, place the result of the 2nd step in the storage tank and carry out shelving and aging for 70 hours;

[0045] The fourth step is to put the aged material in the third step into the mixer, add water with 1% weight of the aged material to mix and stir, then feed it into the vacuum bri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com