Flotation method for lead-zinc oxide ore

A technology of lead-zinc oxide and zinc oxide, which is applied in flotation, solid separation, etc., can solve the problem of difficult to realize the industrial production of lead-zinc oxide ore, can not solve the problem of flotation recovery of fine-grained minerals, and it is difficult to ensure smooth flow and process stability, etc. problems, to achieve the effects of easy production and stable control, improved zinc oxide flotation recovery rate, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

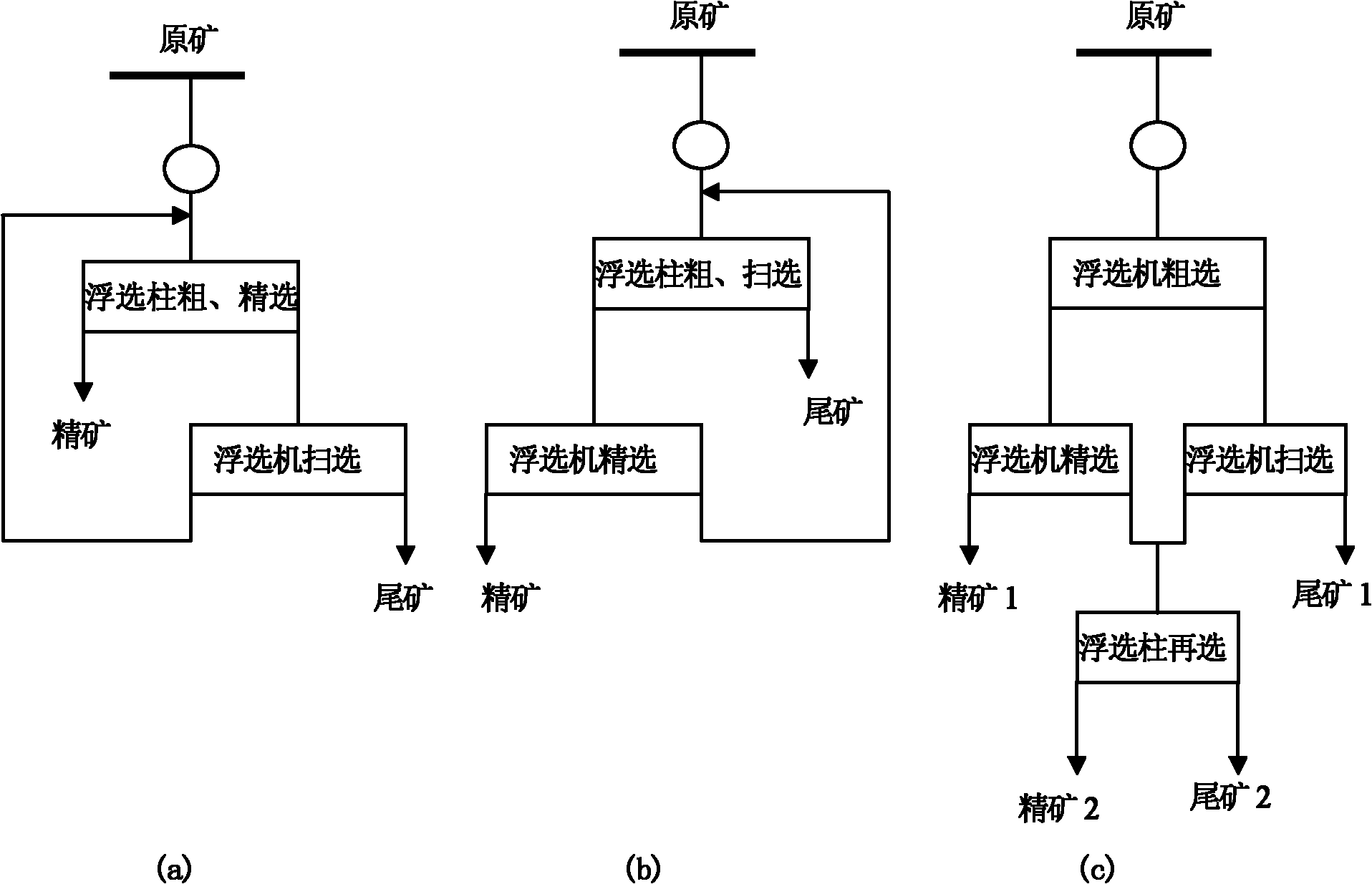

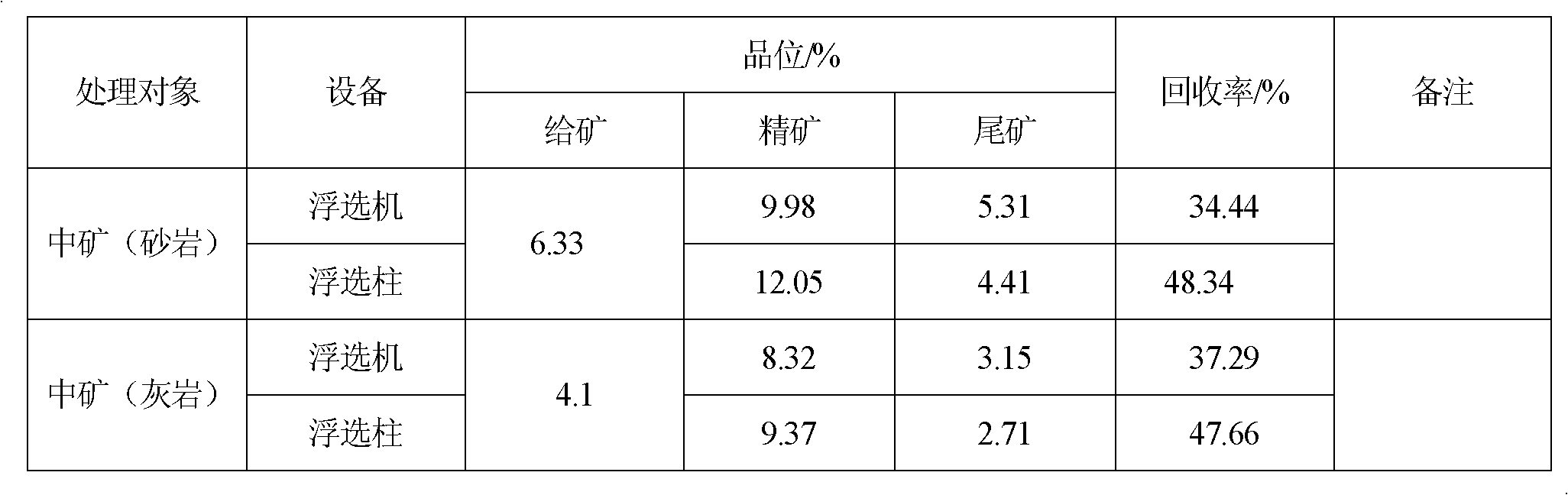

[0030] The principle plan flow chart of the ore re-election process in the combined column-machine process is as follows figure 2 (c), for the re-election of the low-grade lead-zinc oxide ore in Lanping, Yunnan, one operation of one flotation column replaced the three operations of the re-election of the flotation machine (coarse, fine, sweeping, 8 sets of flotation machine), and the comparative test results are shown in Table 1.

[0031] Table 1 The comparison results of the flotation column and the current flotation machine in the middle ore re-election flotation column

[0032]

Embodiment 2

[0034] Column machine combined process, the principle scheme flow chart is as follows figure 2 (a), the rough sweeping operation of the flotation machine is replaced by the flotation column, and the flotation machine is selected to form a column-machine combined process to process the low-grade lead-zinc oxide ore in Lanping, Yunnan. The comparison results with the original flotation machine process are as follows Table 2.

[0035] Table 2 column machine combined process embodiment 2 result

[0036]

[0037]

Embodiment 3

[0039] Column machine combined process, the principle scheme flow chart is as follows figure 2 (b), the rough sweeping operation of the flotation machine is replaced by the flotation column, and the flotation machine is selected to form a column-machine combined process to process the low-grade lead-zinc oxide ore in Lanping, Yunnan. The comparison results with the original flotation machine process are as follows table 3.

[0040] Table 3 column machine combined process embodiment 3 results

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com