Oil seal spring full-automatic sorting system and method based on image detection method

A sorting system and fully automatic technology, applied in the field of image processing and image testing technology, can solve the problems of inapplicable oil seal spring production line online measurement, inability to guarantee measurement accuracy, manual operation, etc., to avoid system calibration trouble and improve accuracy. and stability, the effect of solving processing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

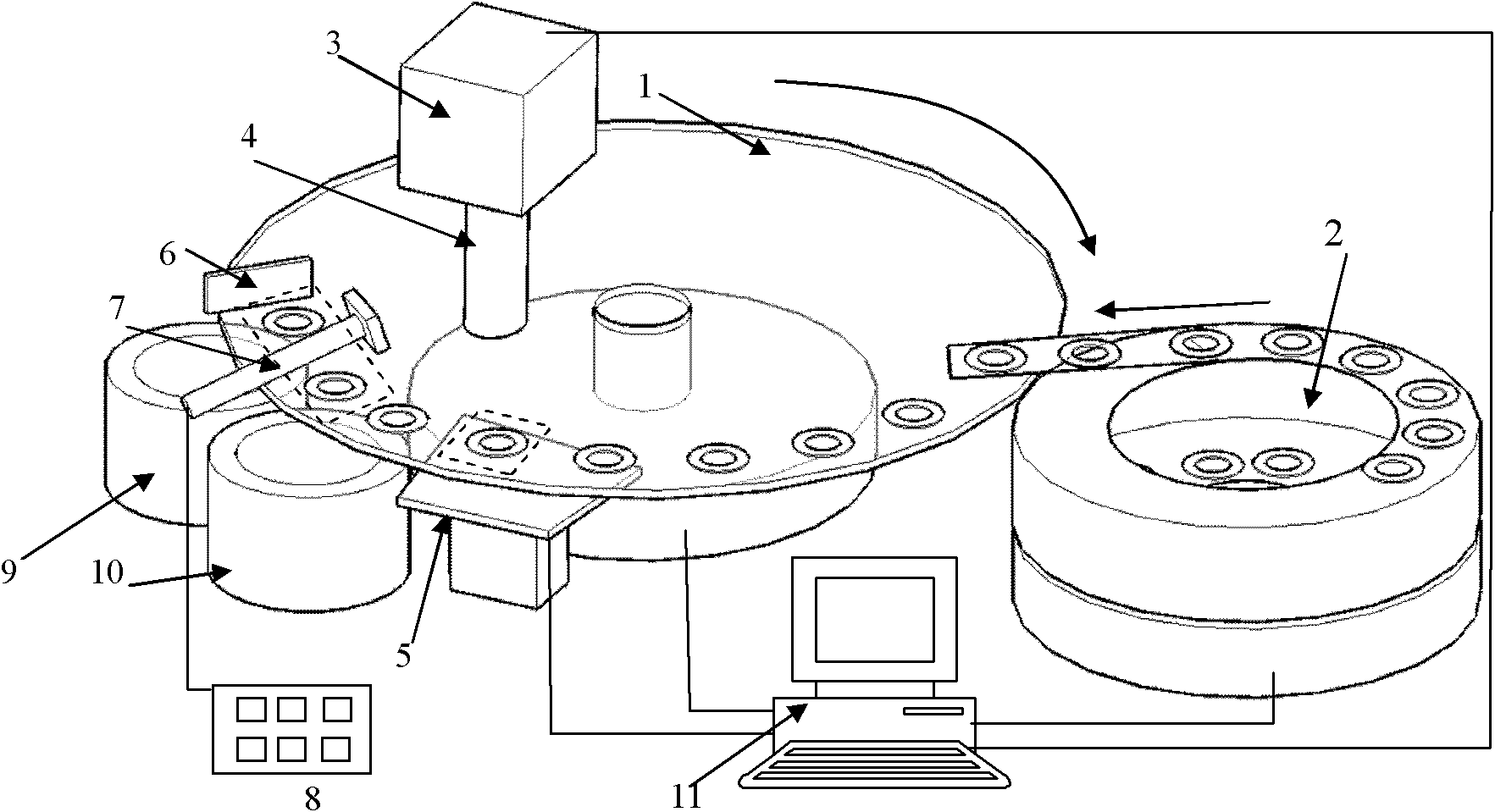

[0040] figure 1 It is a schematic diagram of the system structure of the present invention. The system is divided into three parts: collection and processing components, transport components and sorting components.

[0041] The collection and processing component is composed of CCD camera 3, zoom lens 4, LED backlight 5 and computer 11, which is the core component of the system. The CCD camera 3, zoom lens 4, and LED backlight 5 form a visual inspection system, which is responsible for collecting oil seals. Spring image, with the help of image detection technology and specially designed image processing algorithm to collect, process and analyze the image of oil seal spring, get the spring characteristic data and defect judgment quantity, display the data after summarization, and send control signals to PLC for automatic sorting.

[0042] The transport assembly consists of a vibration plate 2 and a glass turntable 1 . The vibration plate 2 is responsible for sorting the vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com