Method for preparing casting covering slag by utilizing stainless steel cold-rolling pickling wastewater

A technology for pickling wastewater and stainless steel, which is applied in metallurgical wastewater treatment, chemical instruments and methods, neutralization water/sewage treatment, etc. It can solve the problems of difficult utilization, secondary pollution, high treatment cost, etc., and achieve adsorption of inclusions Strong ability, lower production cost, and favorable effect on cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

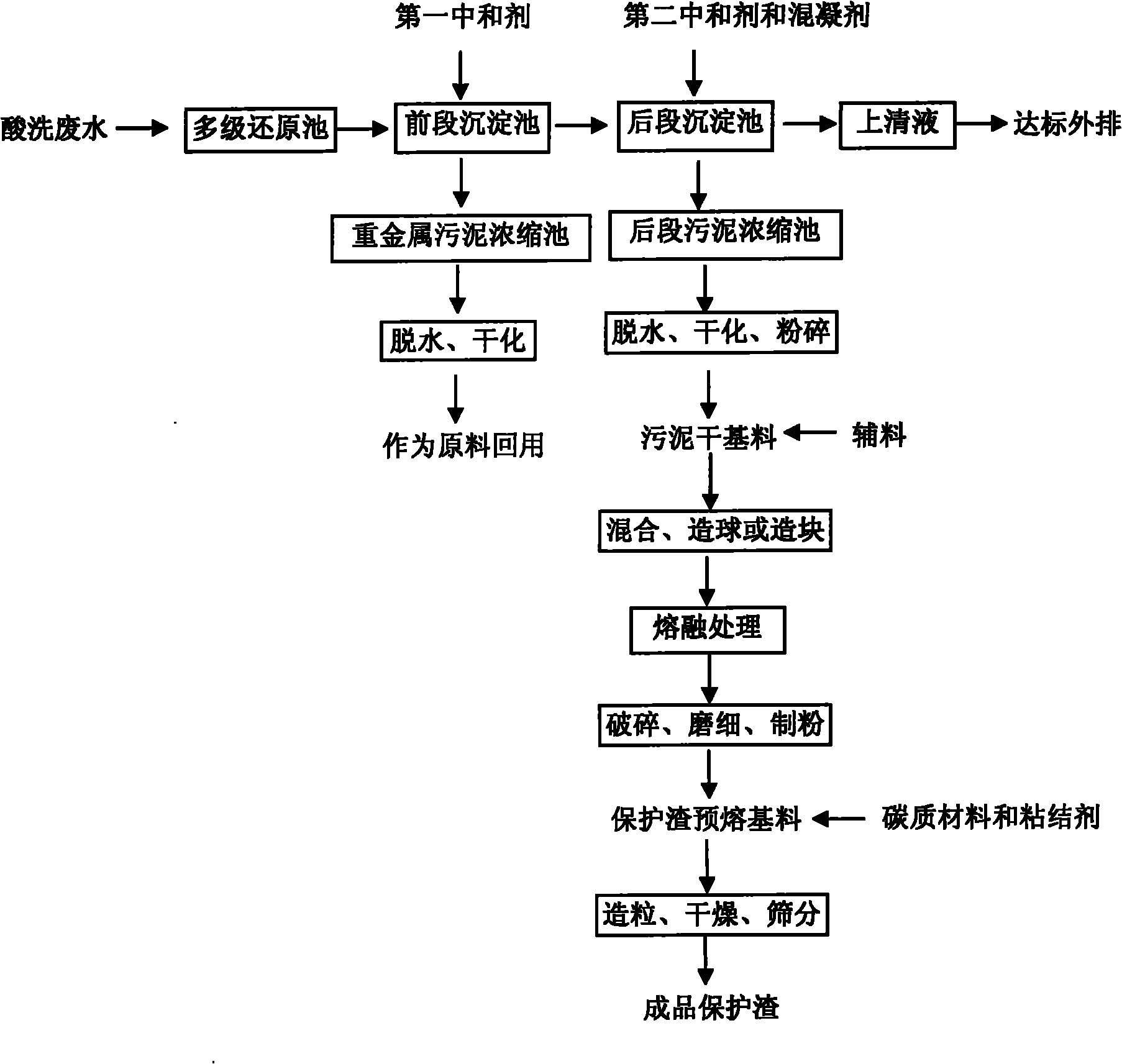

[0060] Such as figure 1 As shown, this is the process flow chart of the method for preparing mold flux for foundry by using stainless steel cold rolling pickling wastewater in the present invention. The method of the present invention is applied to a cold rolling pickling wastewater treatment station of a stainless steel enterprise, and the daily wastewater treatment capacity of this treatment station is 100m 3 / h, the original process route is the traditional Ca(OH) 2 The one-step excessive dosing method produces 50t / d of mixed sludge that is difficult to use. After adopting the two-stage sedimentation process route of the present invention, the total sludge output is 42t / d, which corresponds to a reduction of 8t / d.

[0061] According to the process of the present invention, in the multi-stage chemical reduction treatment of stainless steel cold rolling pickling wastewater, more than 99% of Cr 6+ reduced to Cr 3+ After that, it enters the staged treatment process. In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com