Electromagnetic stirring submerged arc overlaying welding device

A technology of submerged arc surfacing and electromagnetic stirring, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of increasing difficulty of magnetron arc technology, inability to put into production and application, unstable welding quality, etc. Chemical composition segregation and tissue segregation, simple and compact device, and the effect of improving comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

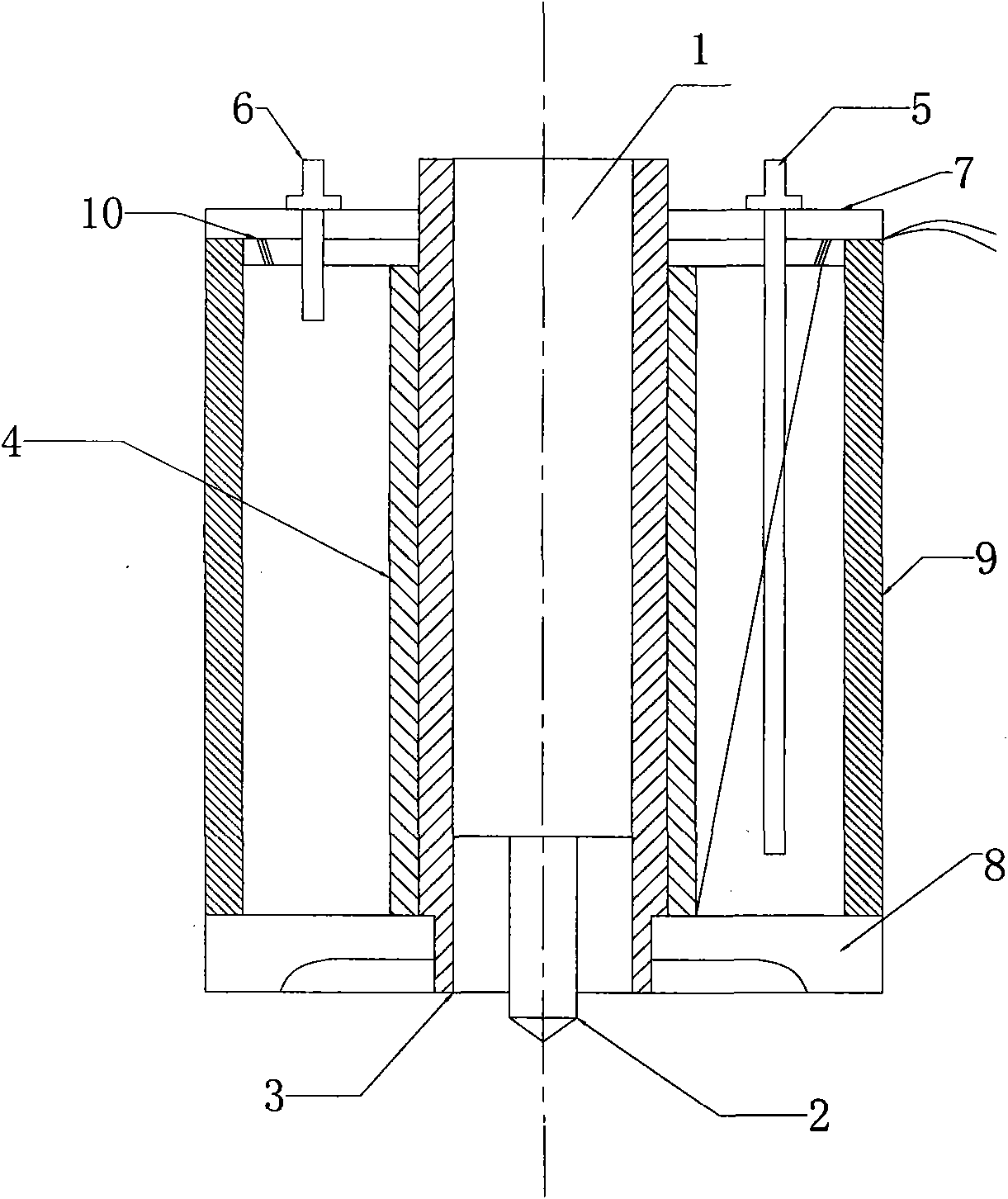

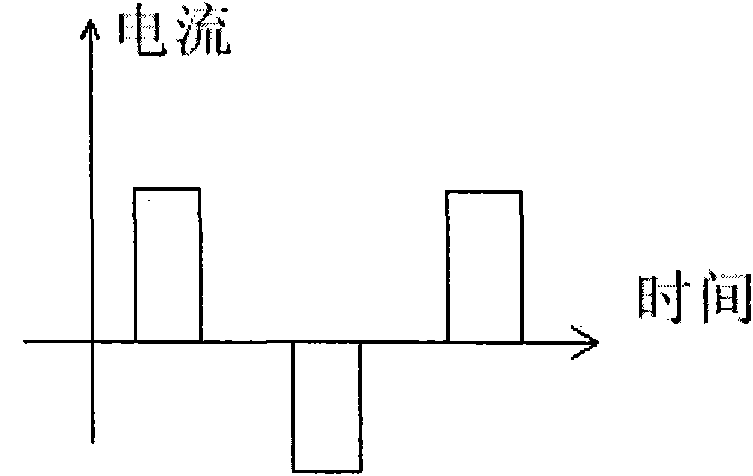

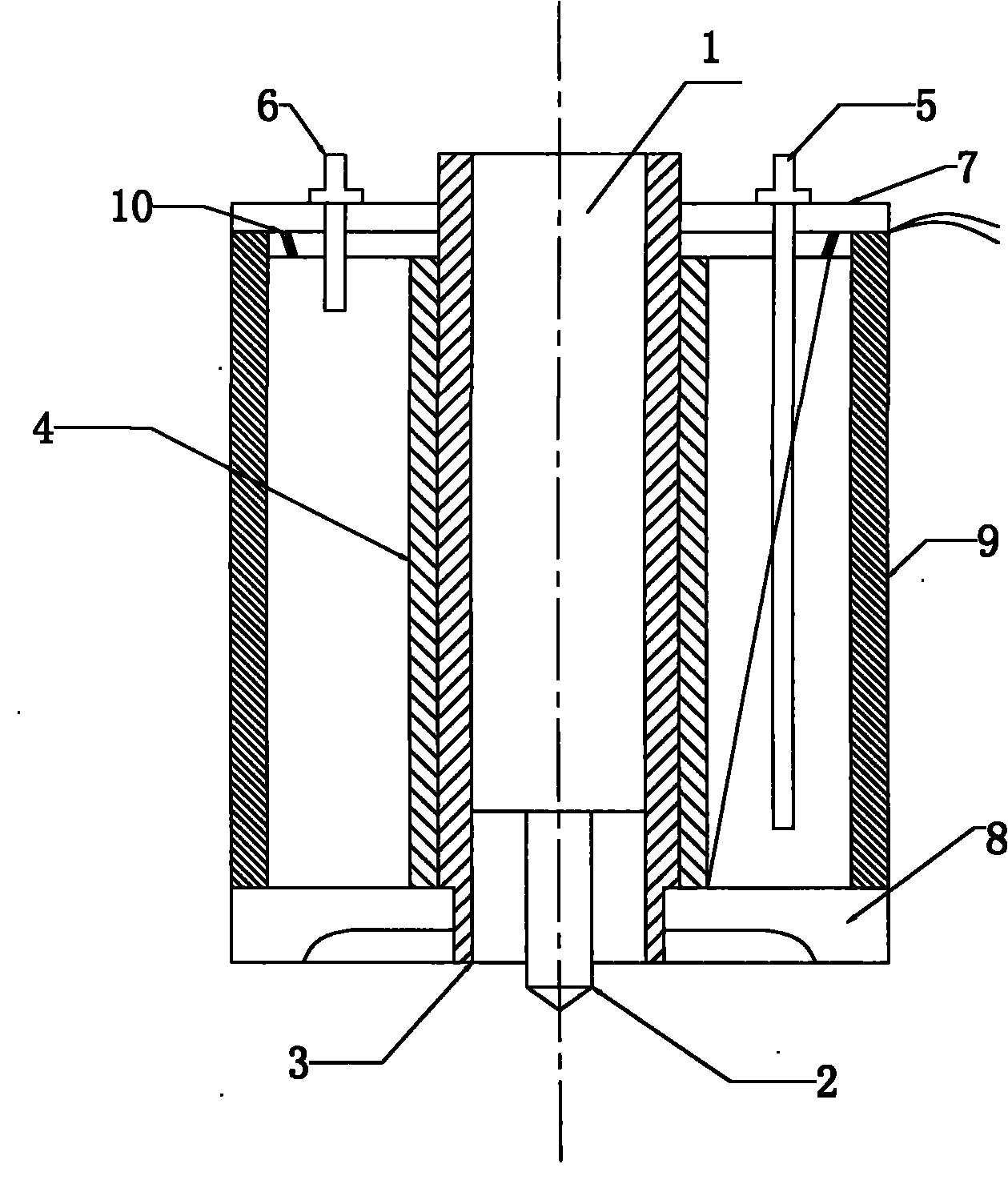

[0017] like figure 1 As shown, the present invention is an electromagnetic stirring submerged arc surfacing device, an electromagnetic stirring submerged arc surfacing device, including a conductive tip 1, and a welding wire 2 passes through the conductive tip 1, and it also includes a sleeve on the conductive tip 1 The exciting coil 4 and the square-wave power supply that provides electric energy for the exciting coil 4, the square-wave power supply is an inverter square-wave pulse power supply.

[0018] The electromagnetic stirring submerged arc surfacing device also includes a magnetic conduction device for enhancing the magnetic field, the magnetic conduction device includes a metal inner sleeve 3, and the excitation coil 4 is wound on the outer wall of the inner sleeve 3 , the contact tip is located in the inner sleeve.

[0019] The electromagnetic stirring submerged arc surfacing device also includes a water cooling structure, the water cooling structure includes an out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com