Explosive welding method of SAF2507 alloy composite steel plate

A 1.SAF2507, composite steel plate technology, applied in welding equipment, welding/welding/cutting items, metal processing, etc., can solve the problem of high price and achieve the effect of high quality and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

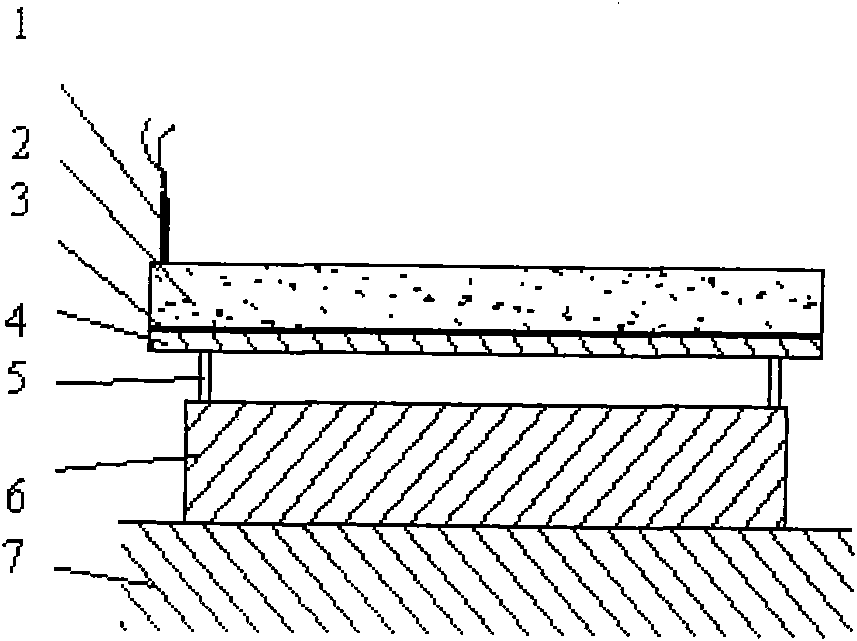

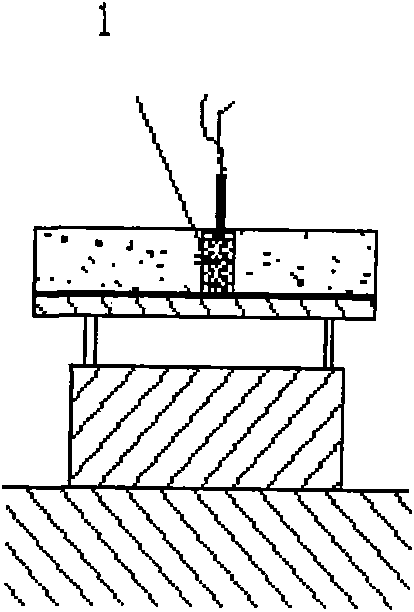

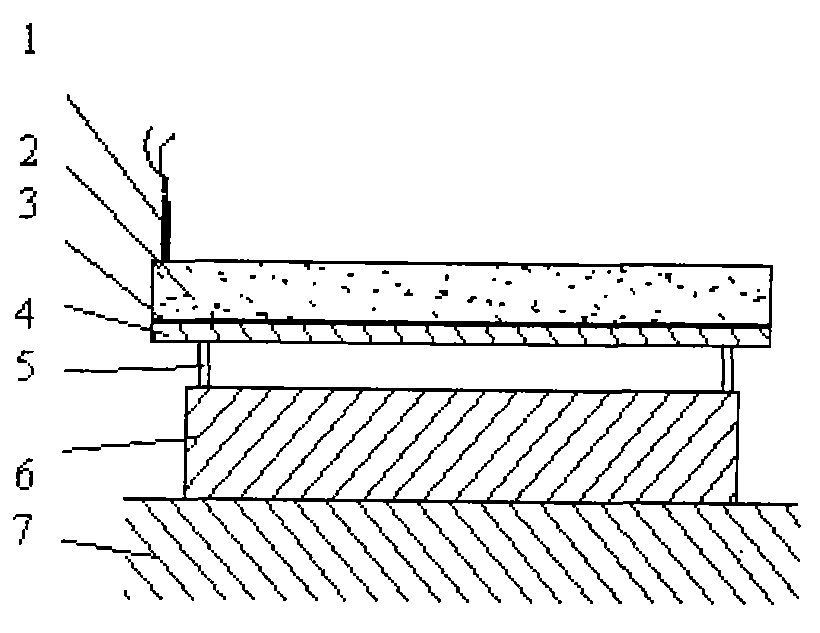

Image

Examples

Embodiment approach

[0022] Substrate blanking process:

[0023] The steel plate should have a quality certificate with clear signs; the steel plate whose material has ultrasonic testing requirements should pass the ultrasonic testing according to the requirements; the steel number, specification, and material inspection number of the material are consistent with the process card.

[0024] Mark the line according to the blanking specification and size of the process card. When marking the line, ensure that the included angle of the four sides of the steel plate is a right angle. The deviation of the length and width of the steel plate is 0-5mm, and the deviation of the diagonal line is not more than 5mm.

[0025] Check the surface quality of the steel plate. If any quality defect is found on the surface of the steel plate, it should be processed in time to pass the qualification. Carry out gas cutting or shearing according to the line, allow an appropriate amount of grinding allowance, remove bur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com