Productive technology of tubular biomass fuel

A biomass fuel and production process technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of low degree of automation, long time consumption, unstable product performance, etc., and achieve a simple structure, low cost, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

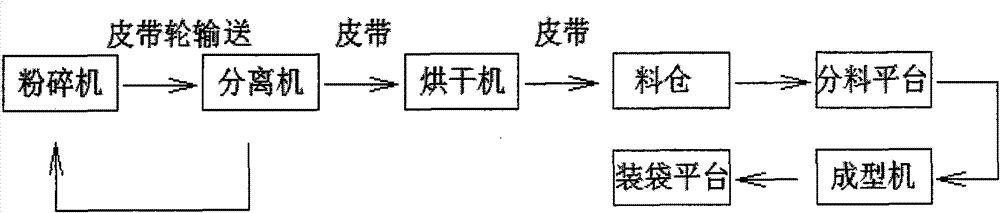

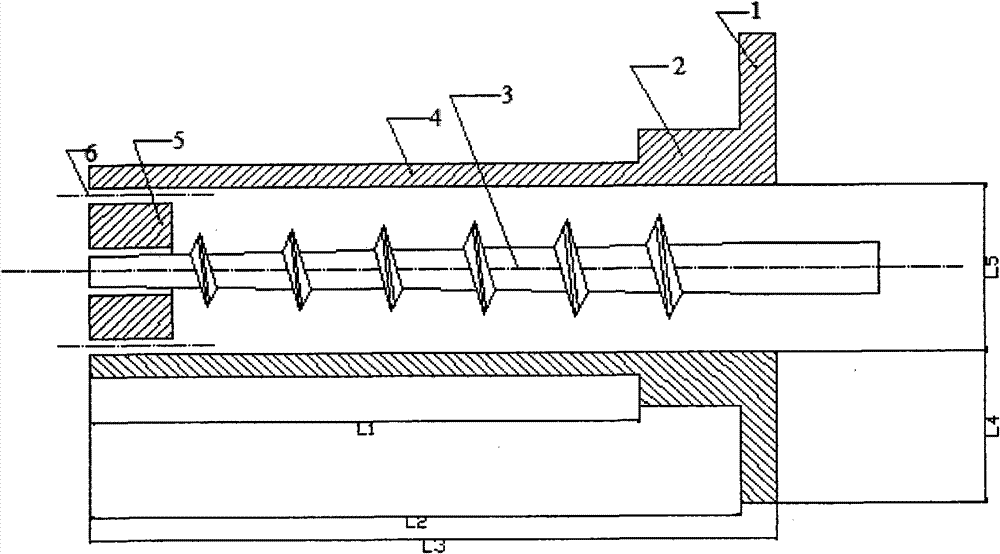

[0022] A specific implementation of a tubular biomass fuel production process will be described in detail below in conjunction with the accompanying drawings.

[0023] Material distributing platform: The raw materials enter the material distributing platform after they come out of the silo. Different raw materials enter the corresponding material bag first, and the bottom of each material bag is connected to the material distributing port. According to different raw material components and proportions, they can be combined and processed to produce different raw materials. physical fuel.

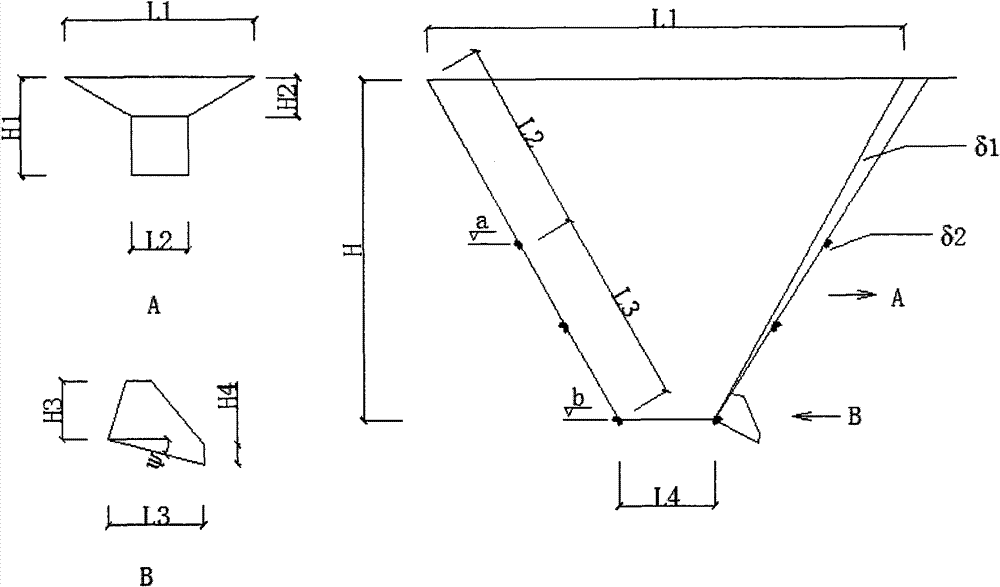

[0024] see figure 2 As shown, the material bag height H1 of the distribution platform for producing tubular biomass fuel is 500mm, the shoulder height H2 is 200mm, the length L1 is 1000mm, and the length L2 is 300mm; the distribution platform for the production of tubular biomass fuel Platform height H is 3460mm, length L1 is 5000mm, length L2 is 2000mm, length L3 is 2000mm, length L4 is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com