Preparation and application of composite anode of microbiological fuel cell

A fuel cell and composite anode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of low output power density, and achieve the effect of improving anode output power density and significant catalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

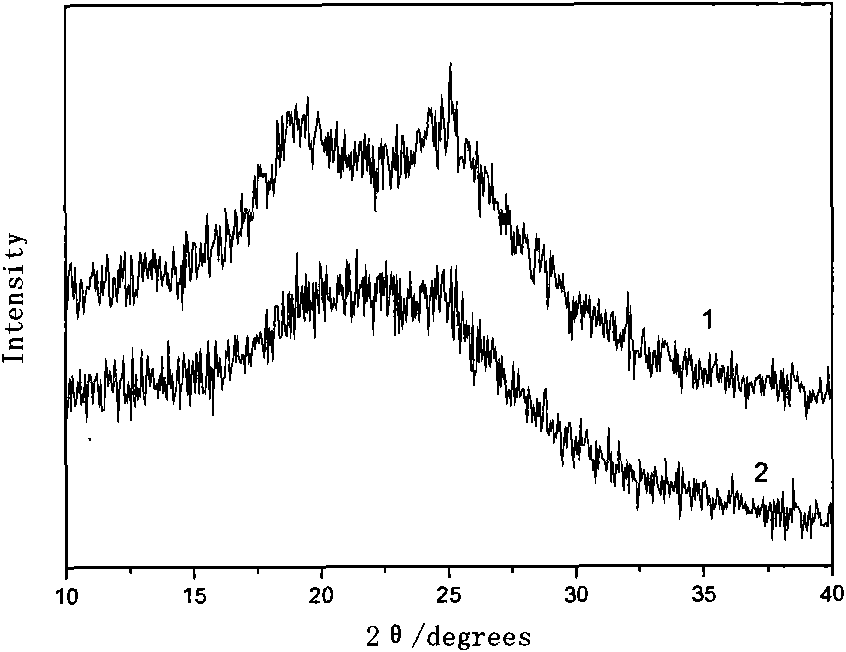

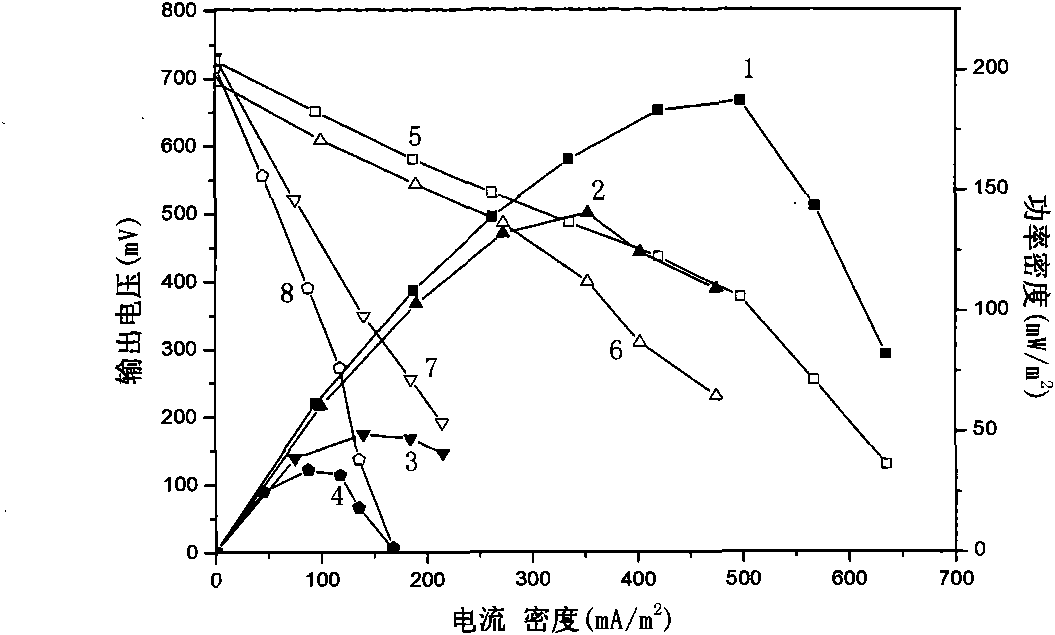

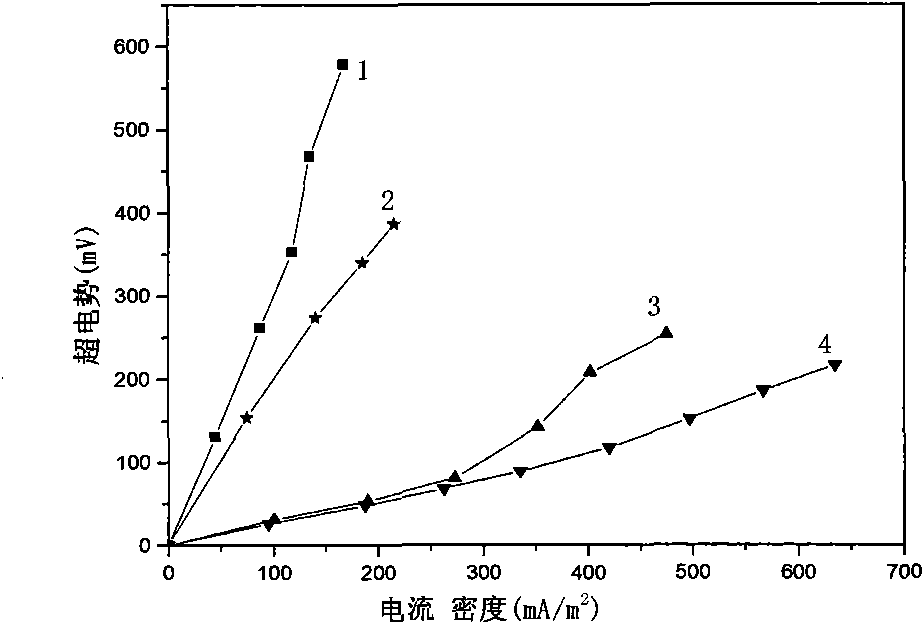

[0049] This example is used to illustrate the preparation method of the composite anode containing manganese salt and polyaniline.

[0050] Measure a certain amount of concentrated sulfuric acid (mass fraction 98%) into a beaker, then pour aniline monomer (re-distilled before use) to make a 300ml solution, and stir magnetically for 5 minutes to dissolve the precipitate. The concentration of sulfuric acid is 1M, and the concentration of aniline monomer is 0.2M. Add 4.45g of manganese dioxide, and stir quickly and evenly. Stand still, react for 15min, and filter with suction. The obtained product was dried in a blast drying oven at 60° C. and crushed. Add the above product to 12M concentrated sulfuric acid at 4°C for sulfonation treatment for 20 minutes, then perform suction filtration, rinse repeatedly with distilled water, dry the obtained product in a blast drying oven at 60°C, and crush it to obtain manganese salt containing and polyaniline anode materials. Connect 2×2cm...

Embodiment 2

[0052] This example is used to illustrate the preparation method of the composite anode containing manganese salt and polyaniline.

[0053] Measure a certain amount of concentrated sulfuric acid (mass fraction 98%) into a beaker, then pour aniline monomer (re-distilled before use) to make a 300ml solution, and stir magnetically for 5 minutes to dissolve the precipitate. The concentration of sulfuric acid is 0.5M, and the concentration of aniline monomer is 0.1M. Add 1.11 g of manganese dioxide, and stir quickly and evenly. Stand still, react for 30min, and filter with suction. The obtained product was dried in a blast drying oven at 55° C. and crushed. Add the above product to 8M concentrated sulfuric acid at 4°C for sulfonation treatment for 30 minutes, then perform suction filtration, rinse repeatedly with distilled water, dry the obtained product in a blast drying oven at 55°C, and crush it to obtain manganese salt containing and polyaniline anode materials. Connect 2×2...

Embodiment 3

[0055] This example is used to illustrate the preparation method of the composite anode containing manganese salt and polyaniline.

[0056] Measure a certain amount of concentrated sulfuric acid (mass fraction 98%) into a beaker, then pour aniline monomer (re-distilled before use) to make a 300ml solution, and stir magnetically for 5 minutes to dissolve the precipitate. The concentration of sulfuric acid is 2M, and the concentration of aniline monomer is 0.5M. Add 17.8 g of manganese dioxide, and stir quickly and evenly. Stand still, react for 10min, and filter with suction. The obtained product was dried in a blast drying oven at 95°C and crushed. Add the above product to 15M concentrated sulfuric acid at 4°C for sulfonation treatment for 10 minutes, then perform suction filtration, rinse repeatedly with distilled water, dry the obtained product in a blast drying oven at 95°C, and crush it to obtain manganese salt containing and polyaniline anode materials. Connect 2×2cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com