Method for preparing hydroxyapatite/composite hole bioactive glass

A technology of bioactive glass and hydroxyapatite, applied in phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of slow bone formation, poor mechanical properties, complicated operation, etc., achieve simple equipment and relieve pain , the effect of shortening the time of bone formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

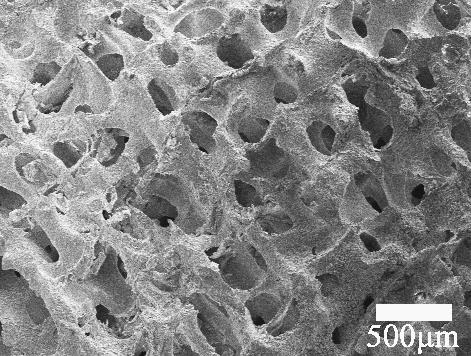

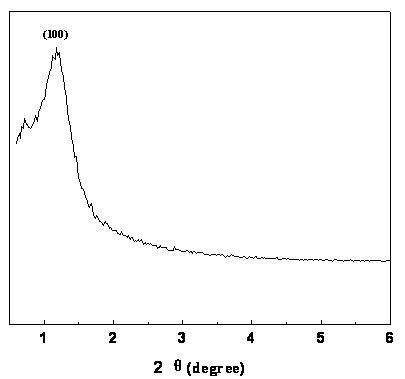

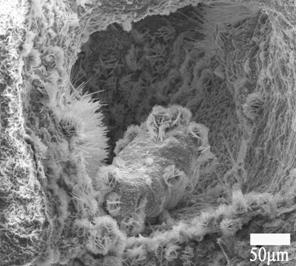

[0011] Specific embodiment 1: The preparation method of hydroxyapatite / composite pore bioactive glass in this embodiment is realized according to the following steps: 1. Dissolve 3 to 5 g of triblock copolymer P123 in a mixed solution of absolute ethanol and hydrochloric acid , and then sequentially add 5-7g of tetraethyl orthosilicate, 1-2g of calcium nitrate and 0.5-1g of ethyl triphosphate, and stir for 1-5h to obtain solution A; 2. Wash the coral with deionized water, and then immerse it to a concentration of 0.1~0.3mol / L NaHPO 4 -NaH 2 PO 4 5-12 hours in the buffer solution, then washed with deionized water, and dried to obtain macroporous hydroxyapatite; 3. Immerse the macroporous hydroxyapatite in solution A for 2-6 hours, take it out and dry it at room temperature, and repeat the operation Immerse and dry once, then immerse in solution A for 2-6 hours, take it out and rinse with deionized water for 3-5 times to obtain an amorphous material; 4. Put the amorphous mater...

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, 3g of triblock copolymer P123 is dissolved in the mixed solution of absolute ethanol and hydrochloric acid, and then sequentially add 5g of tetraethyl orthosilicate, 1g of calcium nitrate and 0.5g of ethyl triphosphate were stirred for 1h to obtain solution A. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0018] Specific embodiment three: the difference between this embodiment and specific embodiment one is that in step one, 5g of triblock copolymer P123 is dissolved in a mixed solution of absolute ethanol and hydrochloric acid, and then 7g of tetraethyl orthosilicate, 2g of calcium nitrate and 1g of ethyl triphosphate were stirred for 5 hours to obtain solution A. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com