Method for controlling centrifugal granulation of molten blast furnace slag

A control method and a blast furnace slag technology are applied in the control field of intelligent centrifugal granulation of molten blast furnace slag, and can solve the problems of affecting the service life of the water cooling wall, the heat exchange effect of the cooling medium, the uneven distribution of slag particles, the splashing of the slag particles, and the like. Conducive to energy recovery, easy operation, avoiding local overheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

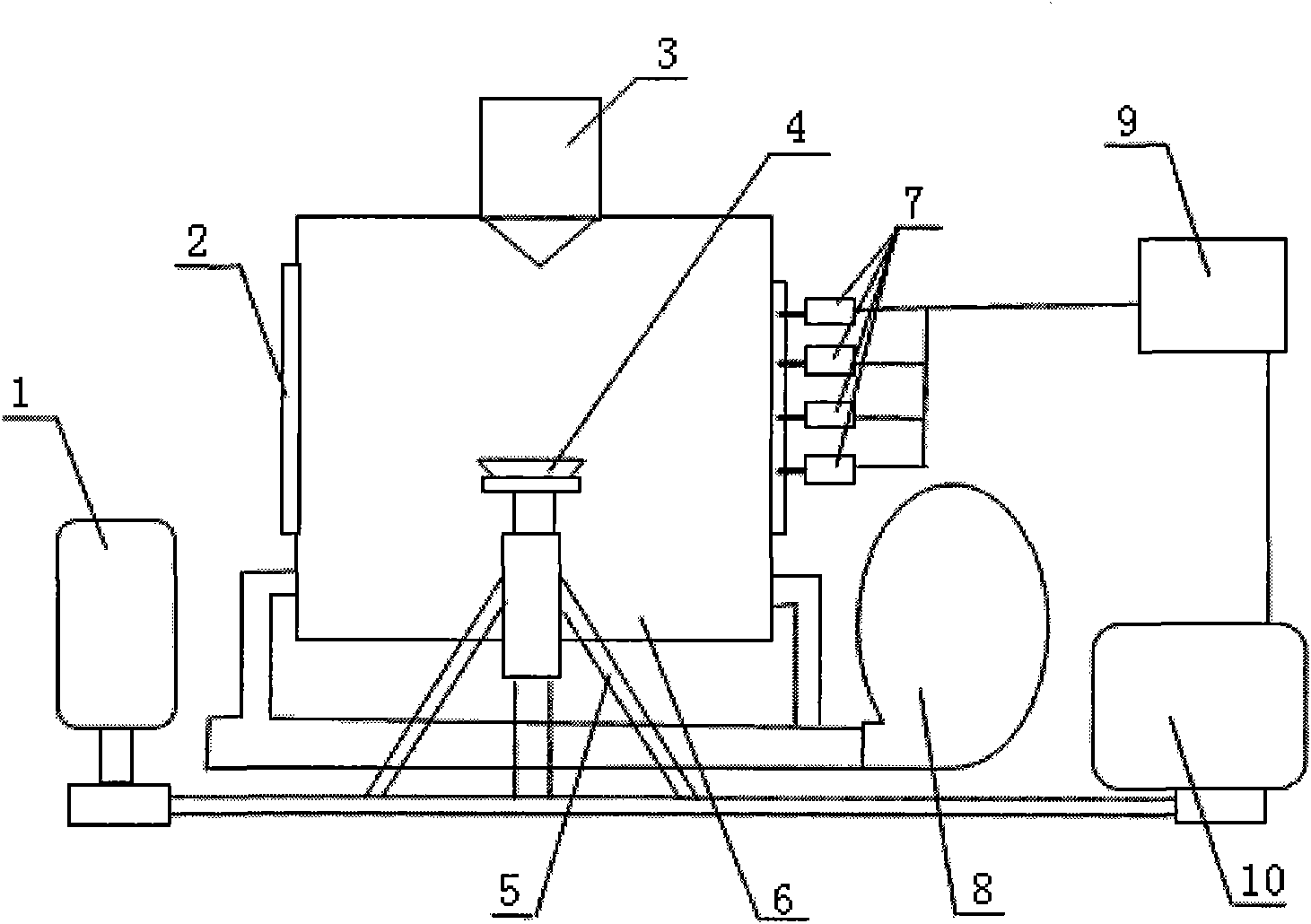

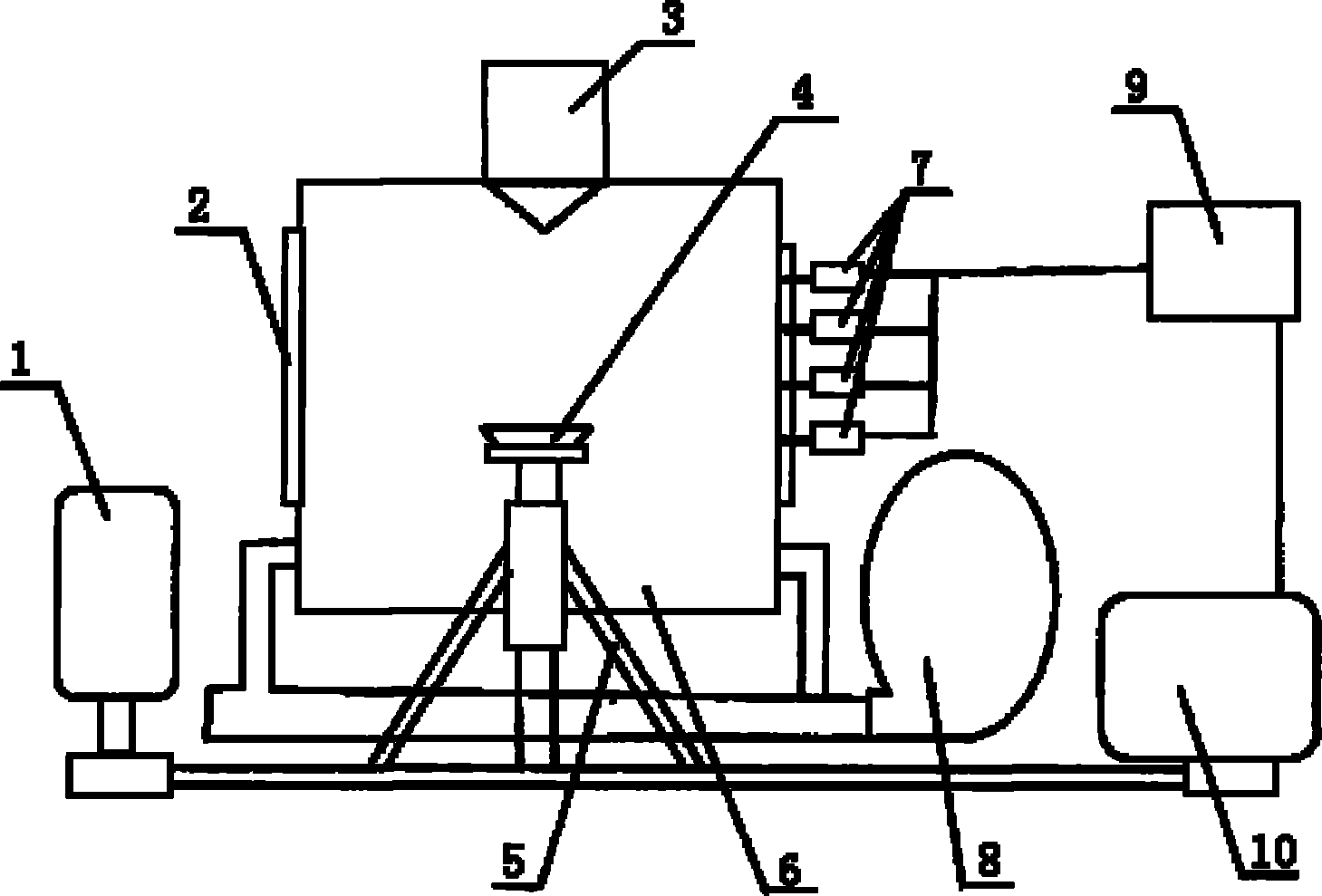

[0013] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0014] See figure 1 , a control method for centrifugal granulation of molten blast furnace slag, the top of the device is provided with a tundish 3, the bottom is provided with a collecting pan 6, the side wall is provided with a water cooling wall 2, and 4 to 8 thermal resistors 7 are arranged on the water cooling wall 2 , the lower part of the rotor 4 is connected with the hydraulic device 10 through the fixed bracket 5, the hydraulic device 10 can control the lifting of the rotor 4, the rotor 4 at the lower part of the tundish 3 is driven by the rotor motor 1 at a speed of 800-1600 rpm Rotating at high speed, the molten blast furnace slag drips from the tundish 3 into the rotor 4, and due to the centrifugal force formed by the high-speed rotor, the blast furnace slag at 1400-1500°C is granulated into particles with a diameter of 1-5 mm, and It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com