Shaft furnace and rotary furnace combined type fire refining process for raw red copper

A pyro-refining and rotary technology, applied in the field of non-ferrous metal smelting, can solve the problems of low utilization rate of shaft furnace, high fuel consumption, increased energy consumption, etc., and achieve the goal of ensuring continuity, increasing large-scale, and improving energy utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

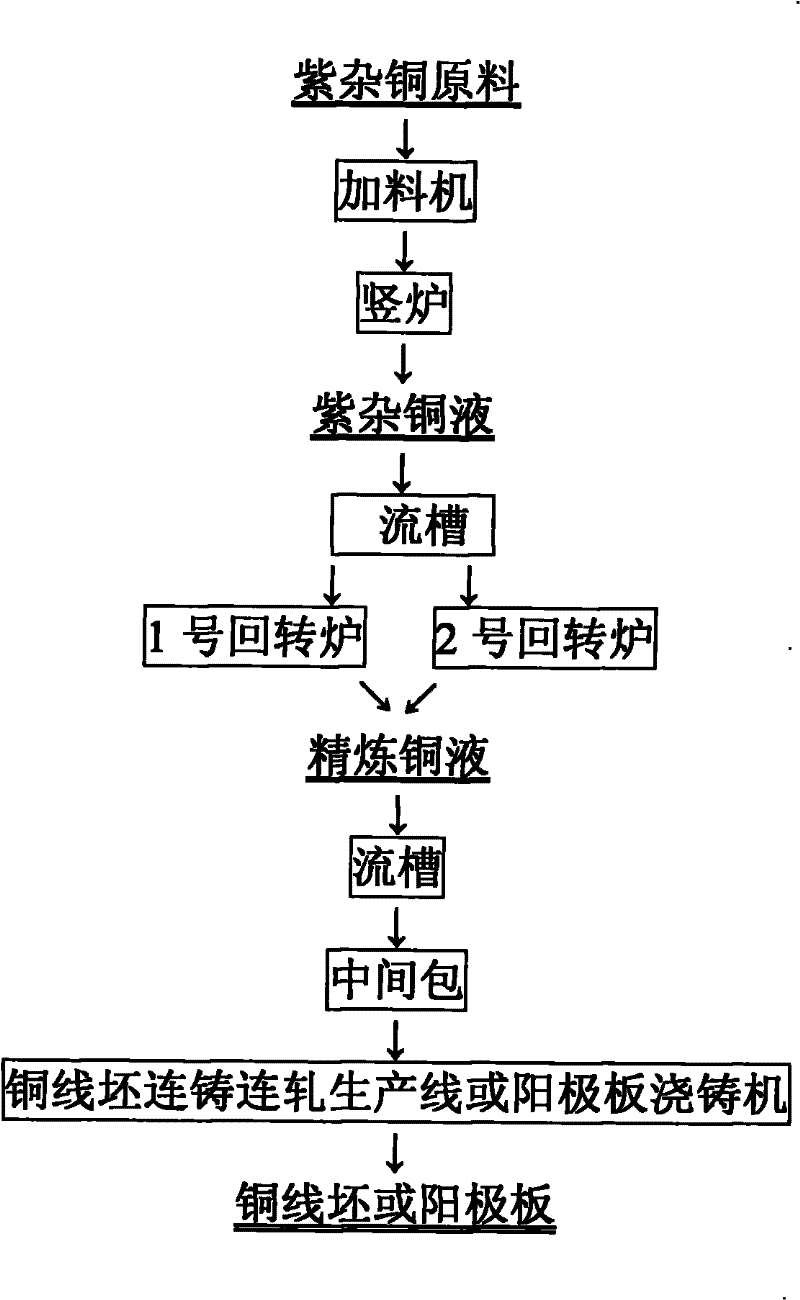

[0044] The fire refining of the project with an annual output of 220,000 tons of copper wire blanks using red copper as raw material, and the method of transporting red copper liquid in the launder, the process steps are as follows:

[0045] ① Pre-treat the raw materials of red copper, remove the inclusions as much as possible, and the processing length or block size should be suitable for loading into the feeder.

[0046] ②Use a forklift to load the red miscellaneous copper raw materials into the feeder type feeder.

[0047] ③ The feeder-type feeder feeds the red miscellaneous copper charge into the shaft furnace with a production capacity of 35t / h.

[0048] ④ The shaft furnace with a production capacity of 35t / h melts the charge, and continuously produces copper liquid, which is introduced into two rotary furnaces with a capacity of 300t through two sets of upper moving launders.

[0049] ⑤ The red miscellaneous copper liquid is first introduced into the first rotary furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com