Piler adaptive fuzzy optimal control method

An adaptive fuzzy and optimal control technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problem of not raising the speed optimization of the stacker, not considering the real-time change of the operating speed, and not considering the stacking Machine speed optimization and other issues to achieve the effect of low cost, convenient implementation, and reduced vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

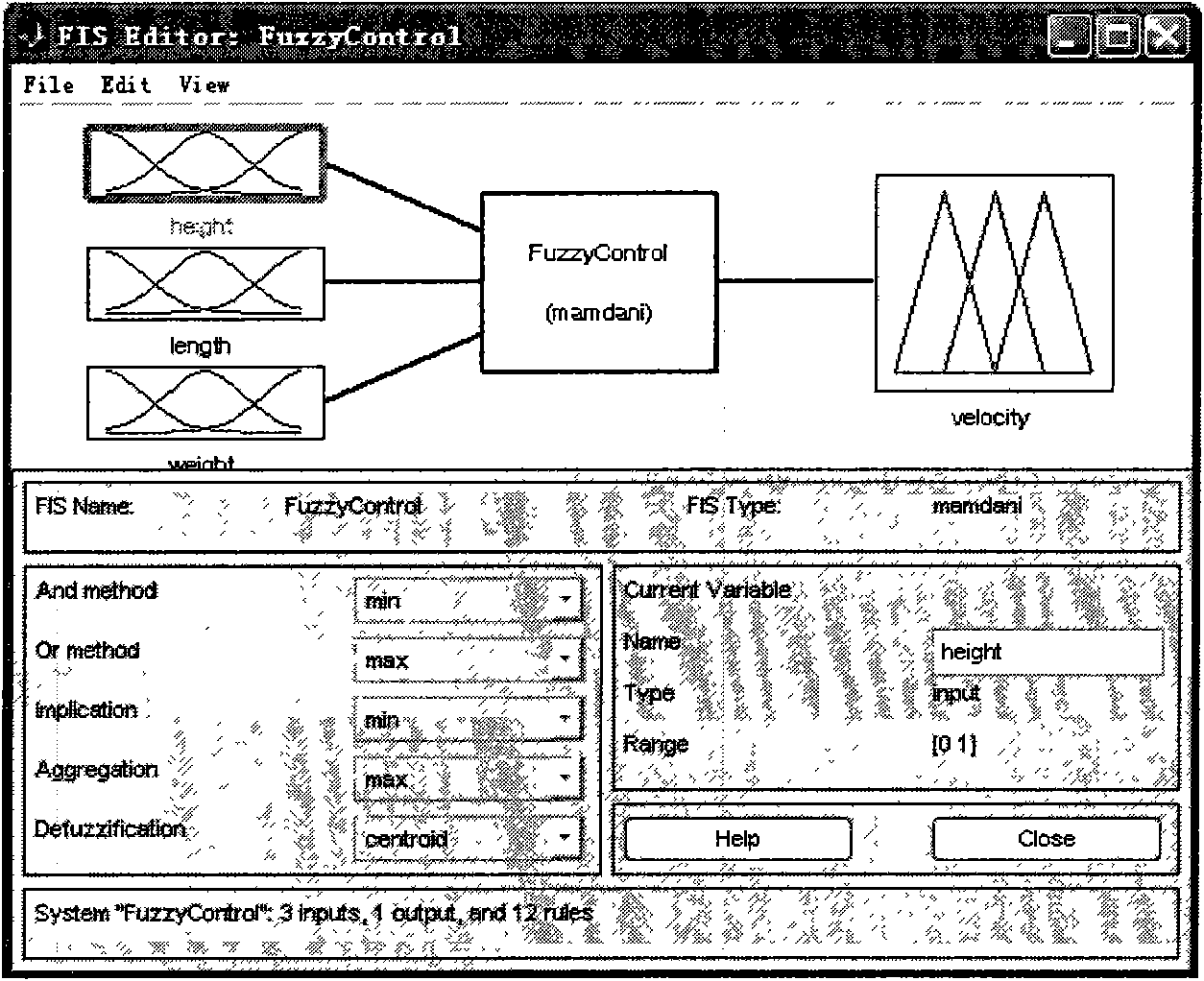

[0026] control figure 1 , fuzzy controller structure design

[0027] We use the fuzzy fuzzy toolbox under Matlab to design the fuzzy control algorithm, the control structure is as follows figure 1 As shown, the input variables of the fuzzy control module include the height of the stacker, the horizontal distance length between the stacker and the target location, and the weight of the cargo on the loading platform. The output variable is the horizontal speed of the stacker.

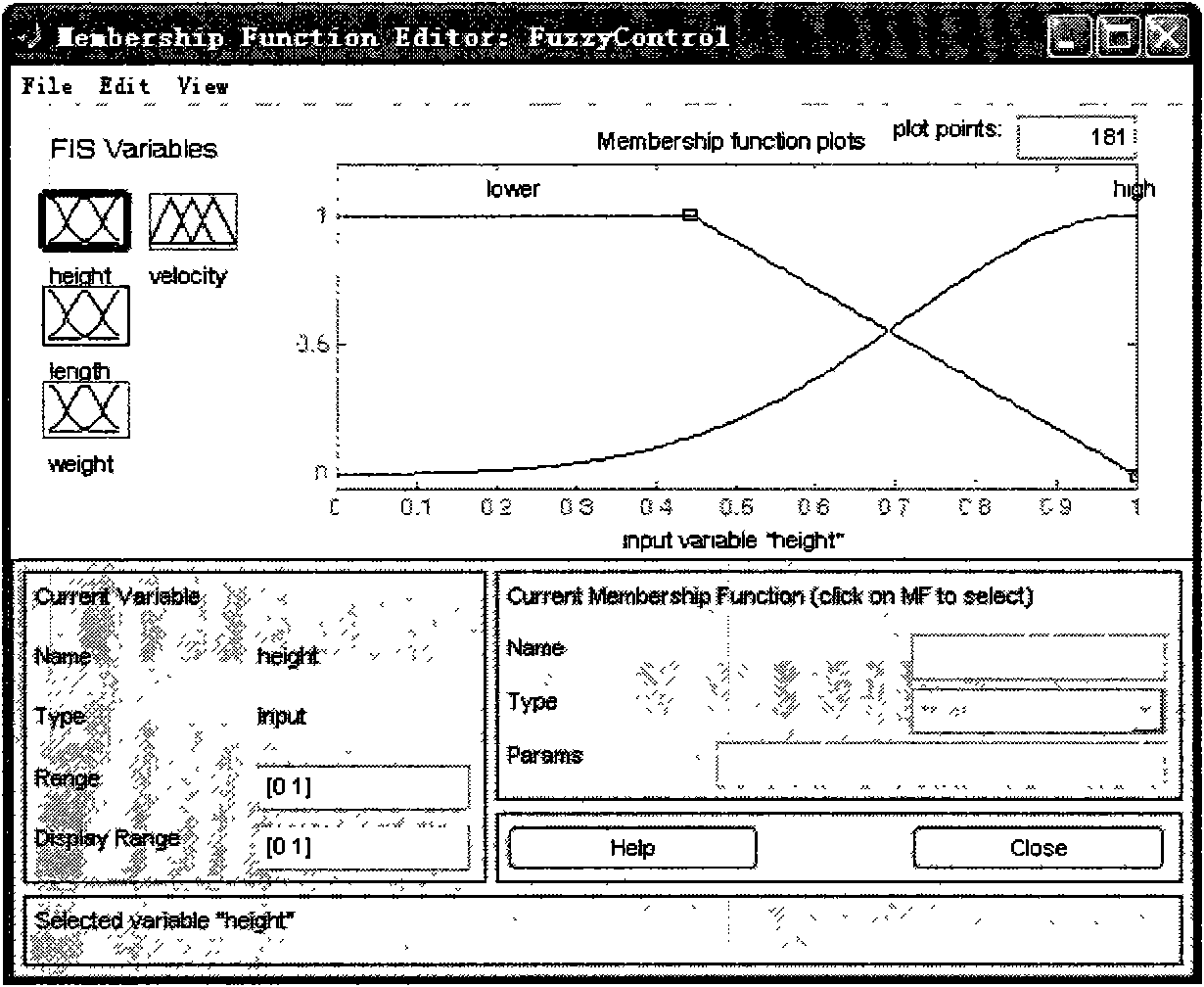

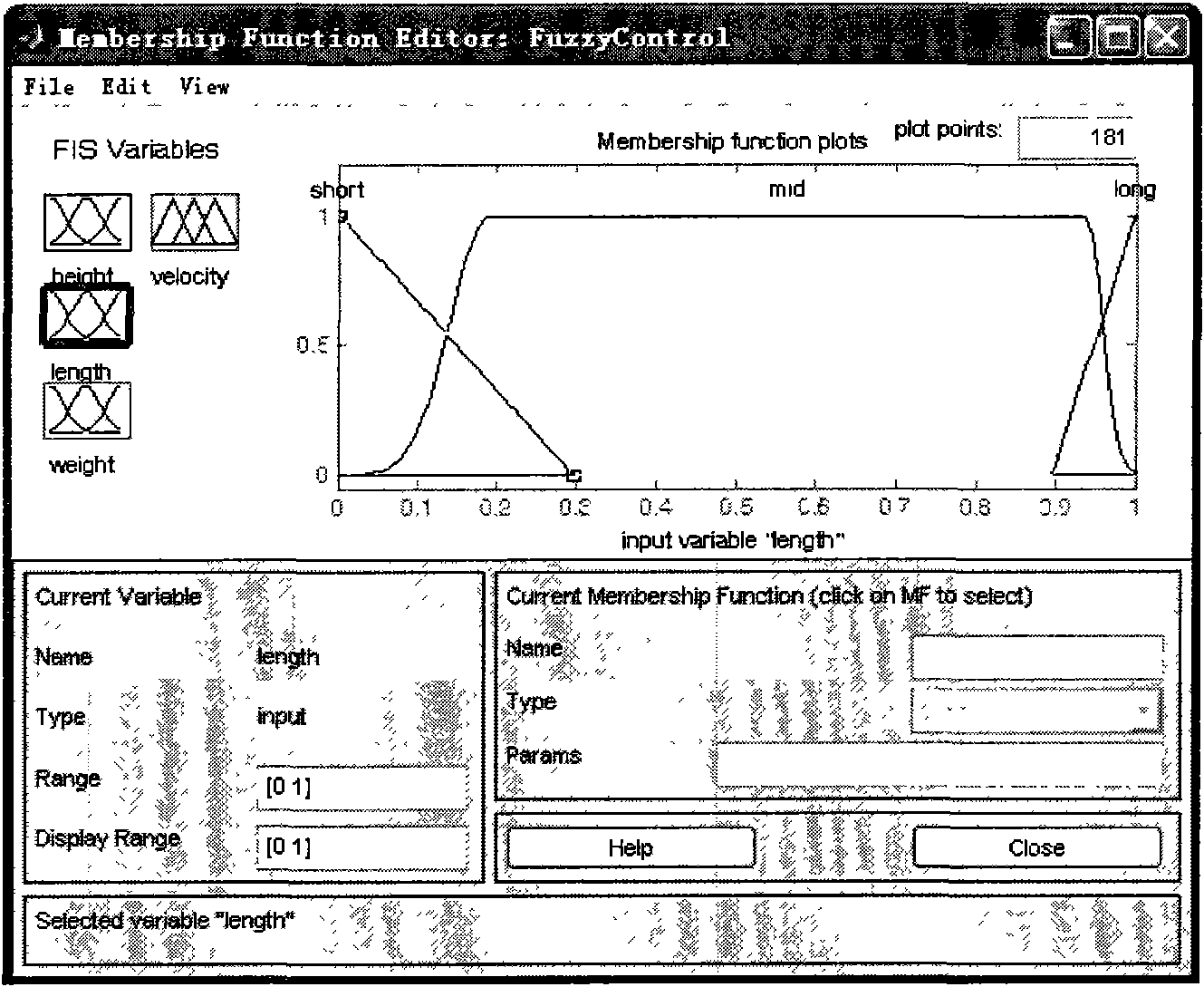

[0028] control Figure 2-5 , fuzzy variable membership function design

[0029] The design of membership function in fuzzy control is the key to whether the output of fuzzy control is smooth or not. Before designing the membership function, we assume that the value ranges of the height of the cargo, the length of the horizontal distance between the stacker and the target location, the weight of the loading platform, and the horizontal speed of the stacker are all 0 ~1 (normalized).

[0030] The membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com