Construction engineering structure mode for tower wind power generation station

A technology for wind turbines and towers, applied in wind turbine components, wind power generation, wind engines, etc., can solve the problems of high power network cable connection costs, low unit installation density, and adverse effects on service life, so as to facilitate maintenance and management , Expand the total installed capacity, reduce the effect of power line loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

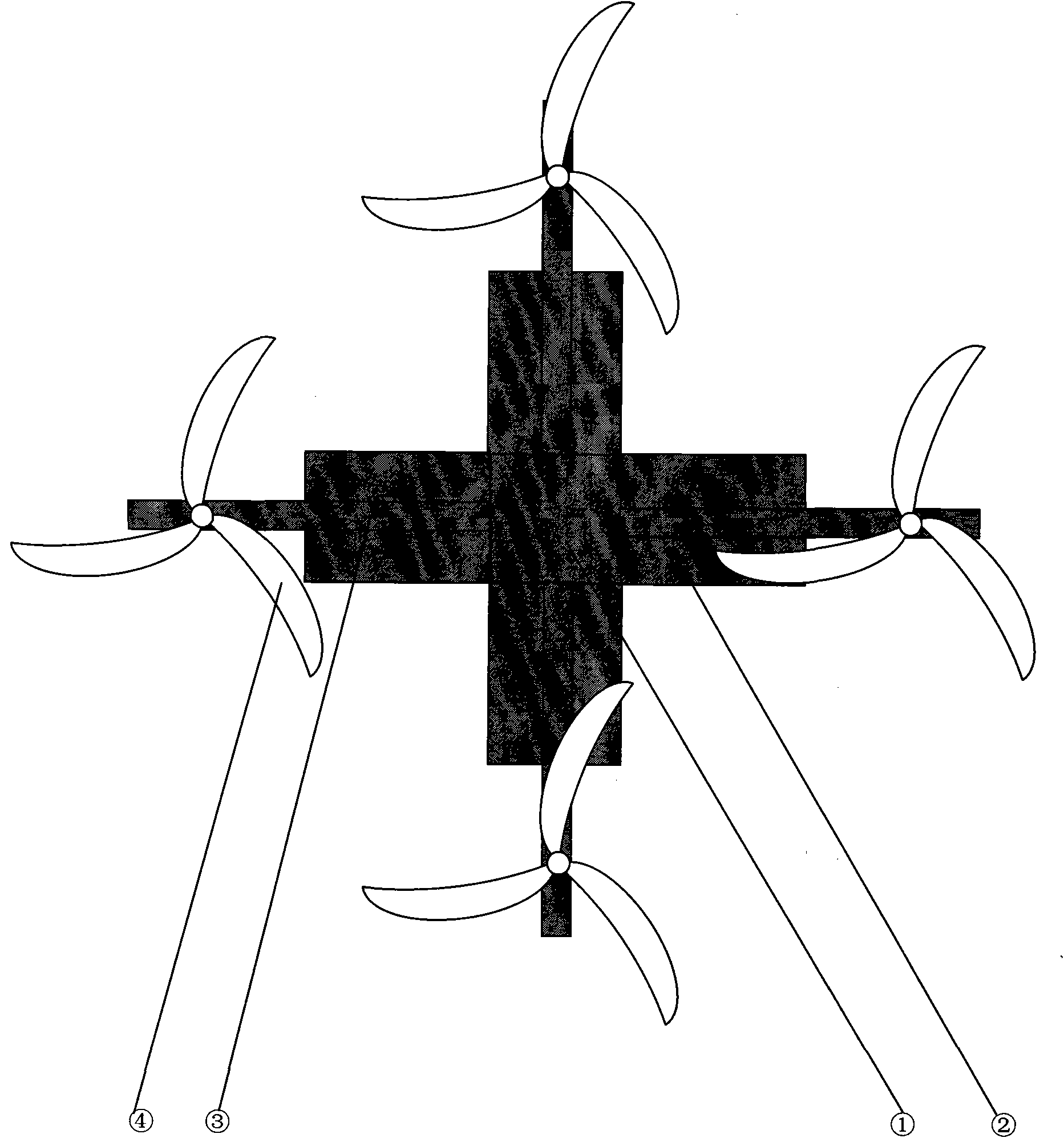

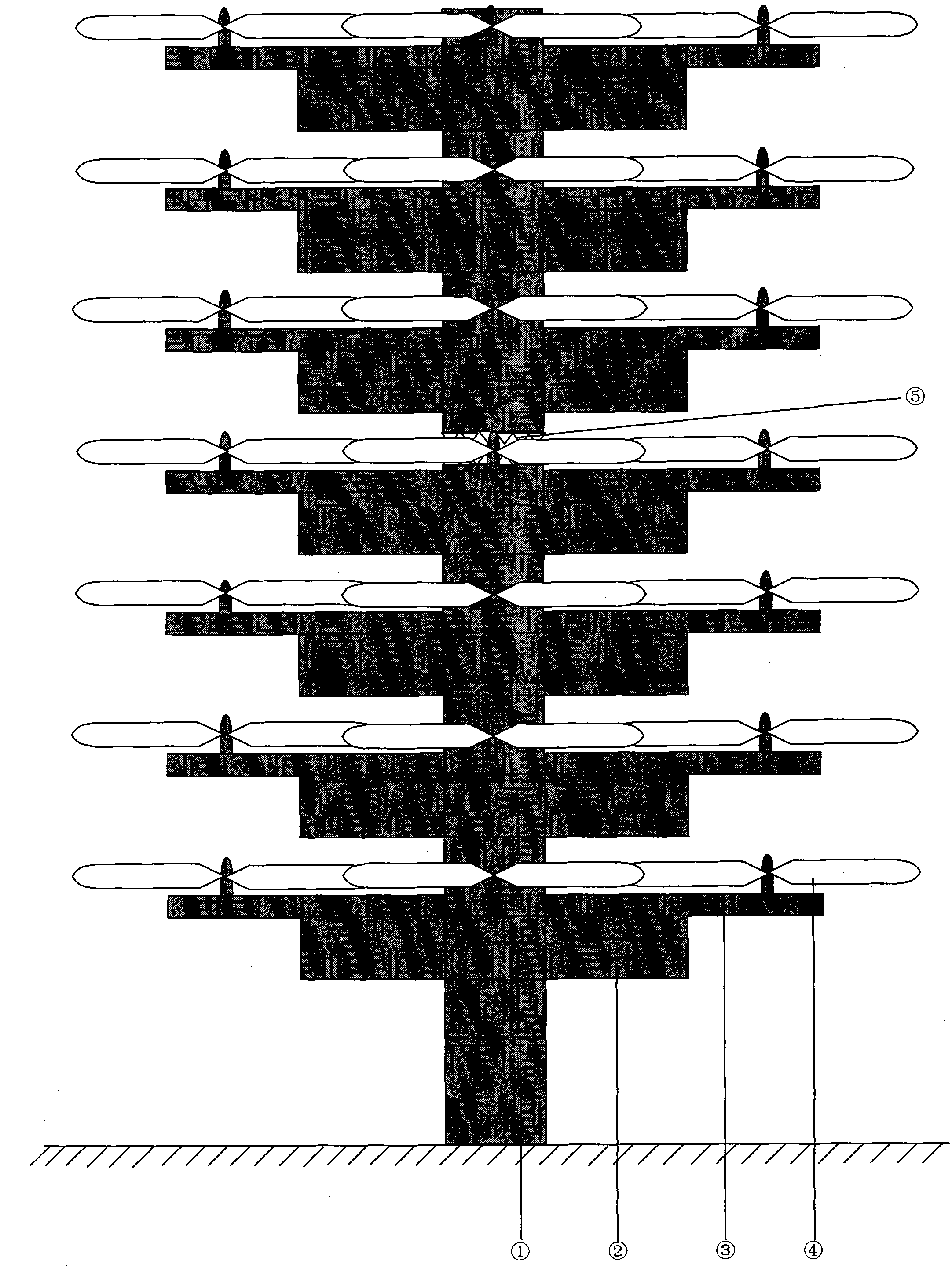

[0018] 1. Choose the combination and construction method of the towers according to the terrain, landform and region. In general, in flat open areas such as plains, grasslands, Gobi, beaches, etc., towers can be distributed in rows and columns to form large and super large wind power stations; in uneven areas such as mountains, hills, and islands In a narrow area, a single or multiple combined towers can be built to build medium and small wind power stations.

[0019] 2. Tower design. The height design of the tower, in general, in plains, grasslands, Gobi, beaches and other open areas with flat terrain, the height of the tower should exceed 300 meters, and can even be designed according to the technical limit; in uneven areas such as mountains, hills, islands, etc. In a narrow area, the height of the tower should be determined according to the specific conditions of all aspects. The floor height of cantilever beams and suspended buildings can generally be designed as a floor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com