Liquid-nitrogen freeze drying machine and control method thereof

A technology of liquid nitrogen freezing and drying machine, which is applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., and can solve the problems of only reaching -80°C, the limitation of reproducibility of the freeze-drying process, and large heat intrusion. , to improve the temperature range and accuracy, overcome the limitations of the heat transfer oil properties, and reduce the number of heat transfers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

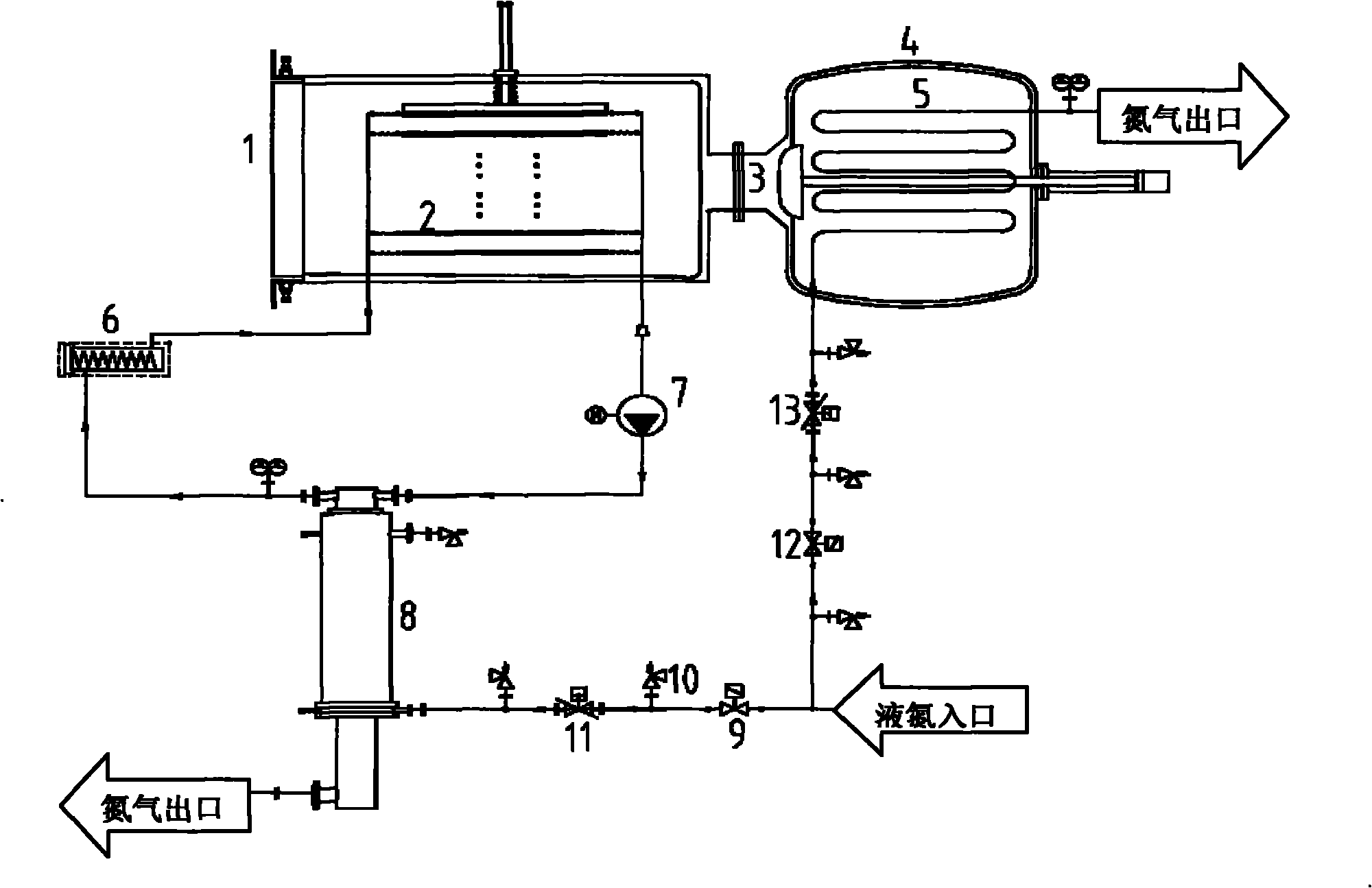

[0041] figure 2 It is a structural schematic diagram of the liquid nitrogen freeze dryer of the present invention.

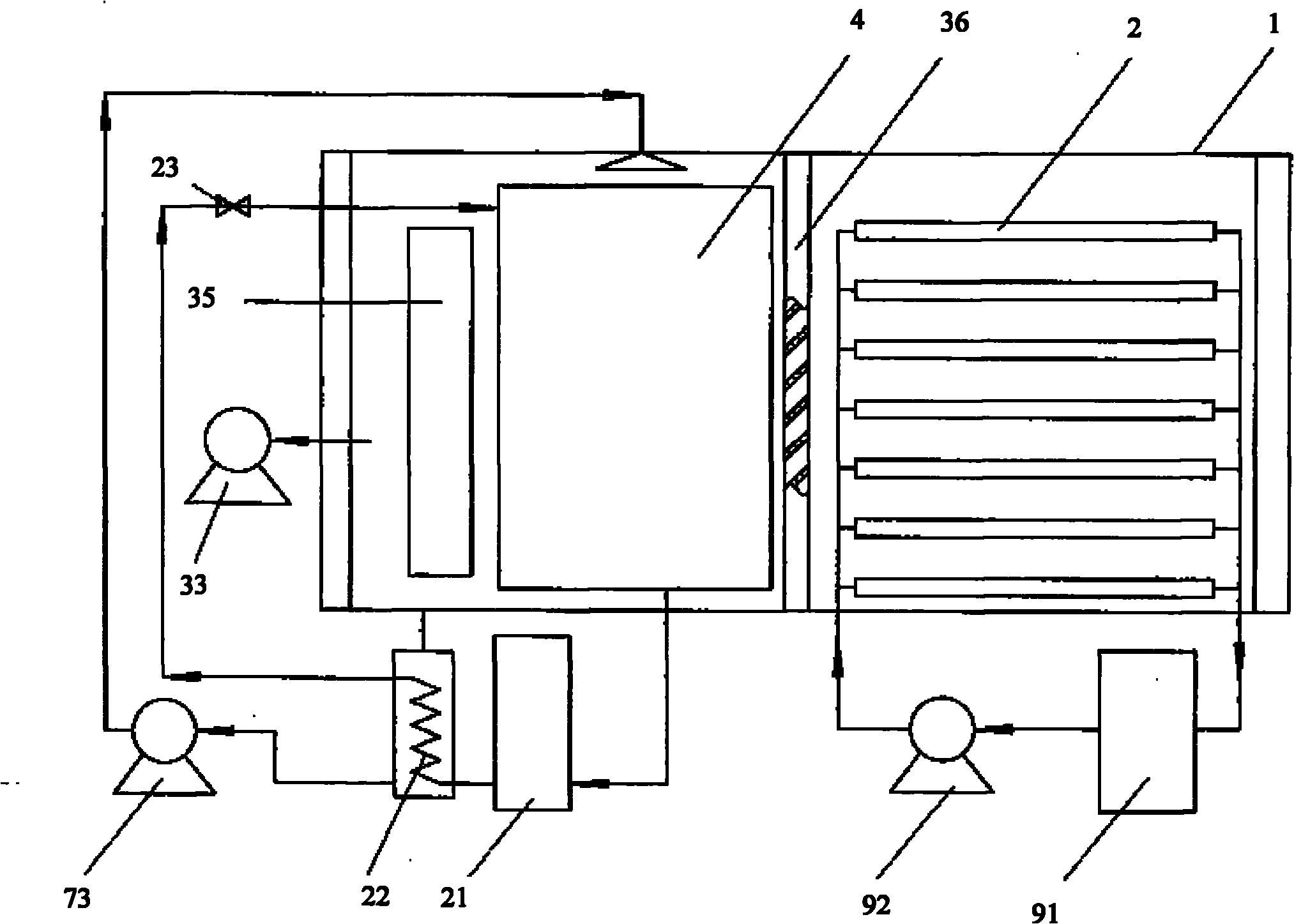

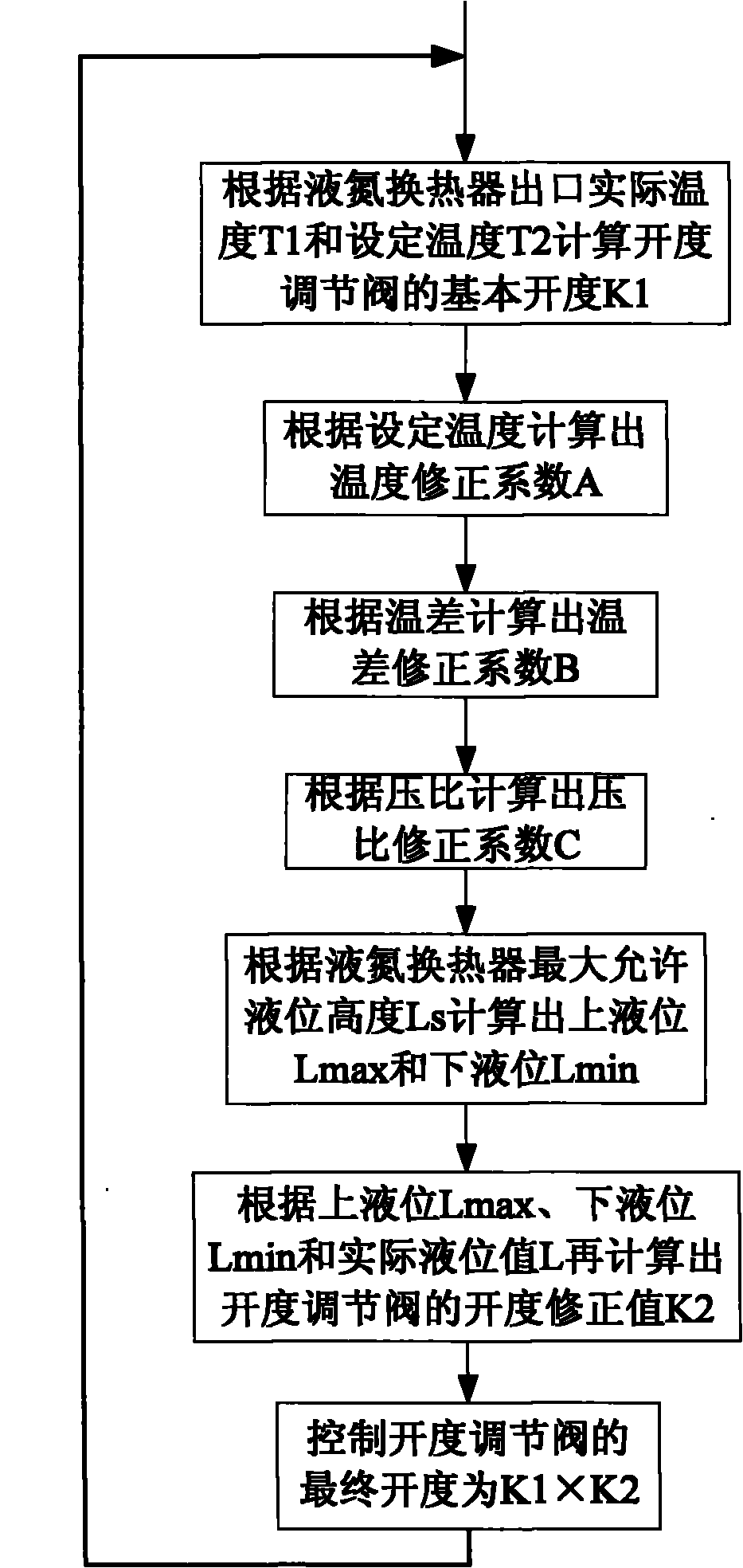

[0042] See figure 2 , the liquid nitrogen freeze-drying machine of the present invention comprises a freeze-drying box 1, and described freeze-drying box 1 is provided with plate layer 2, and described plate layer 2 is connected with circulating pump 7, liquid nitrogen heat exchanger 8, electric heater 6 ; a cold trap 4, the coil 5 is arranged in the cold trap 4; wherein, the freeze-drying box 1 and the cold trap 4 are connected through the septum valve 3; the liquid nitrogen heat exchanger 8 and the first electromagnetic valve 9. The first opening regulating valve 11 is connected; the coil 5 is connected with the second solenoid valve 12 and the second opening regulating valve 13; the first solenoid valve 9 and the second solenoid va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com