Microbial fuel cell and method for enhancing electricity generation performance of microbial fuel cell

A technology of fuel cells and microorganisms, applied in the direction of biochemical fuel cells, fuel cells, fuel cells, etc., can solve the problems of expensive electron transfer intermediates, limited range of power increase, and microbial toxicity, so as to improve electron transfer efficiency and output The effect of large power increase and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in more detail below in conjunction with accompanying drawing example:

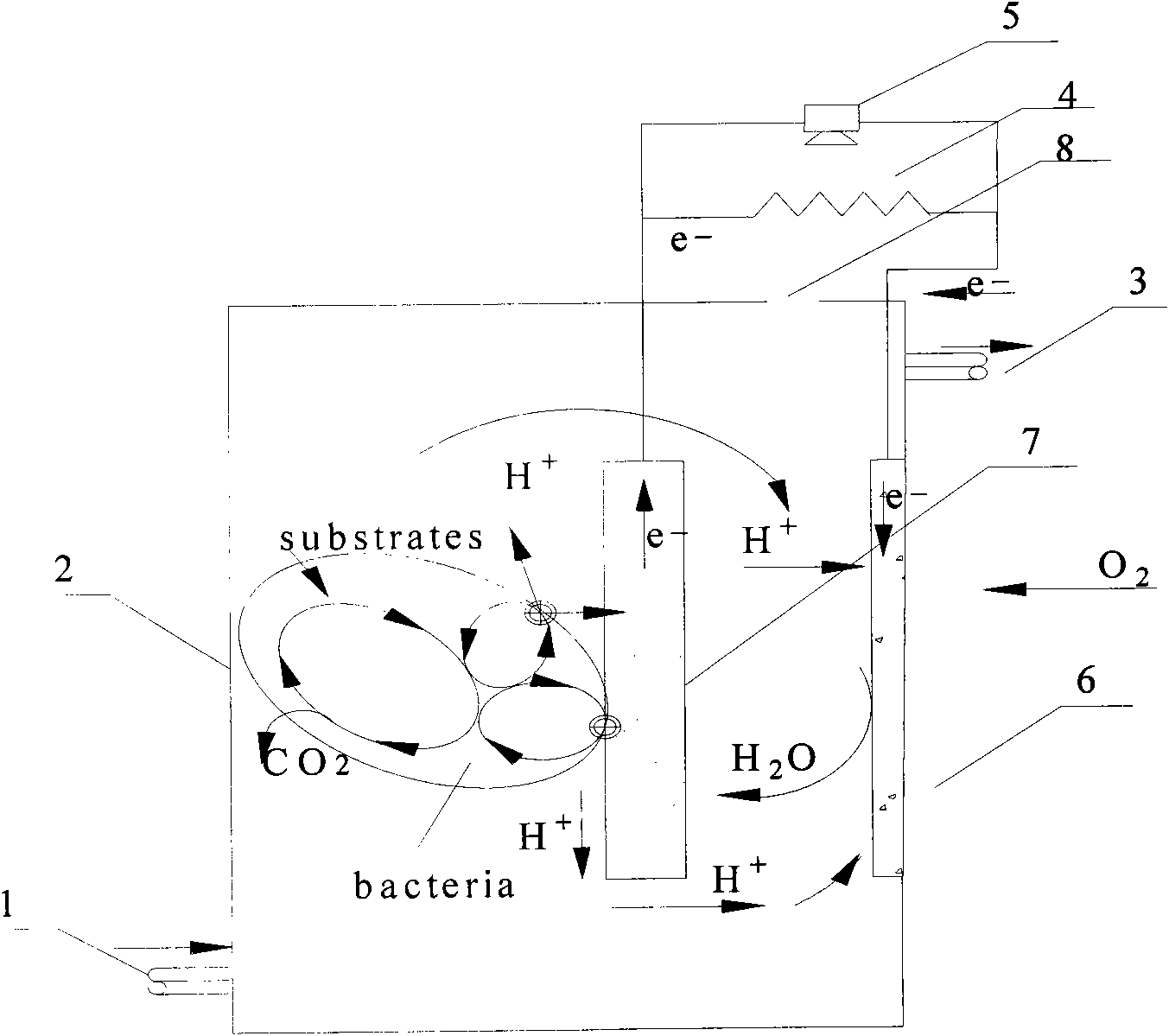

[0016] combine figure 1 , to construct a square reactor, that is, a single-chamber microbial fuel cell without a diaphragm and without a mediator. The anode material is carbon felt, the cathode is a gas electrode containing metal catalysts such as Ag, and the distance between the two poles is 0.5-2.0cm. There is a water inlet 1 at the lower end of the reactor, and a water outlet 3 at the upper end. The upper part of the container has a sealing cover, and the sealing cover is provided with a reference electrode jack 8. The two electrodes are connected by copper wires and connected with the load 4 to form a closed loop. The adjustment range of the load is 1-10000Ω, and the electricity production performance data of the battery is automatically collected and recorded by the data collection device 5 . The reaction chamber of the battery of the present invention is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com