Process for synthesizing diamond

A synthesis process, diamond technology, applied in the application of ultra-high pressure process, etc., can solve the problems of irregular crystal shape, time-consuming, low efficiency, etc., and achieve the effect of complete and regular crystals, improved extraction rate, and avoiding more nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

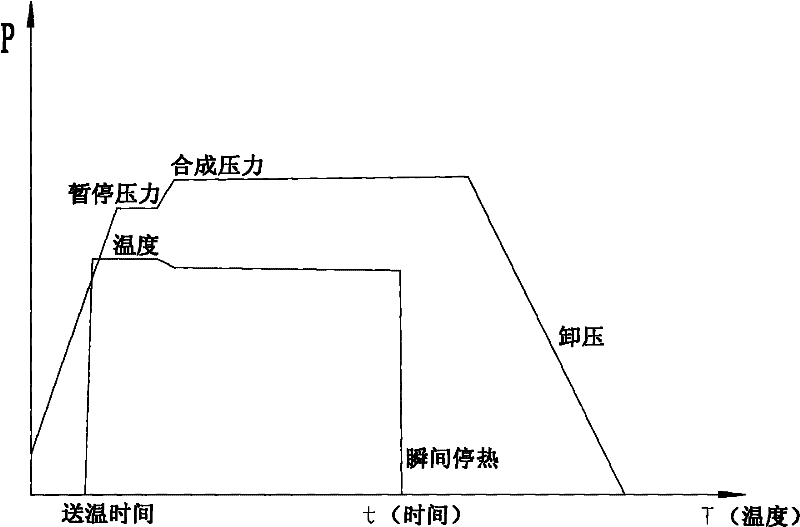

[0020] Diamond synthesis process, the steps are: (1) Put the synthetic block of pyrophyllite into the high-pressure chamber of the six-sided press, and push the six pistons of the six-sided press forward under the action of the booster pump to make the six-sided press The six cemented carbide tops of the press are filled with liquid and pressurized. After the pressure reaches 4MPa, the six-sided top press is connected to the overpressure to 55MPa. During the process of increasing from normal pressure to 55MPa, the pressure increase speed is controlled at 1Mpa / s; Press for 4 minutes, then pressurize to a synthesis pressure of 70MPa in 15 seconds, in order to fully melt the graphite column (graphite powder and metal catalyst powder) in the synthesis cavity of the pyrophyllite synthesis block, so that the graphite is fully converted; During the pressurization process, start heating when the pressure is 35MPa, so as to prevent the pyrophyllite from being unable to seal the heat und...

Embodiment 2

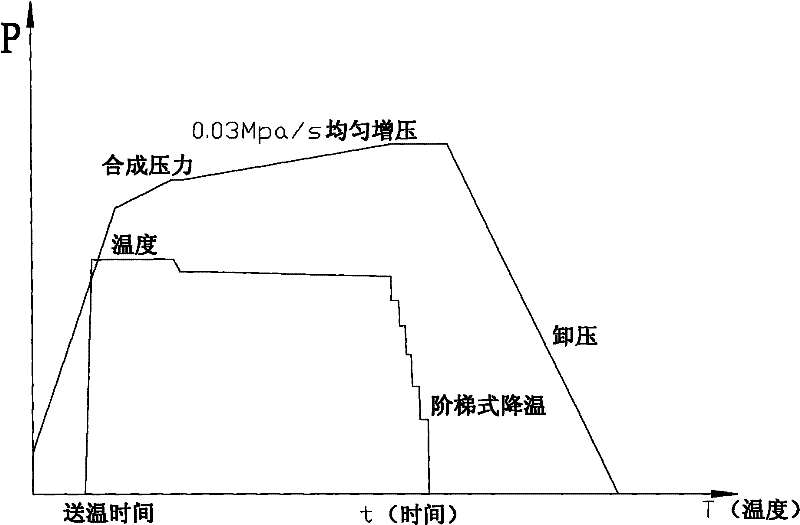

[0022] Diamond synthesis process, the steps are: (1) Put the synthetic block of pyrophyllite into the high-pressure chamber of the six-sided press, and push the six pistons of the six-sided press forward under the action of the booster pump to make the six-sided press The six tungsten carbide tops of the press are filled with liquid and pressurized. After reaching the pressure of 5MPa, the six-sided top press is connected to overpressure to 59MPa, and the pressure increase speed is controlled to 0.5Mpa / s during the process of increasing from normal pressure to 59MPa; Hold the pressure for 6 minutes, then pressurize to a synthesis pressure of 75MPa in 18 seconds, in order to fully melt the graphite column (graphite powder and metal catalyst powder) in the synthesis cavity of the pyrophyllite synthesis block, so that the graphite is fully converted; from normal pressure to 75MPa During the supercharging process, the heating starts when the pressure is 38MPa, so as to prevent the ...

Embodiment 3

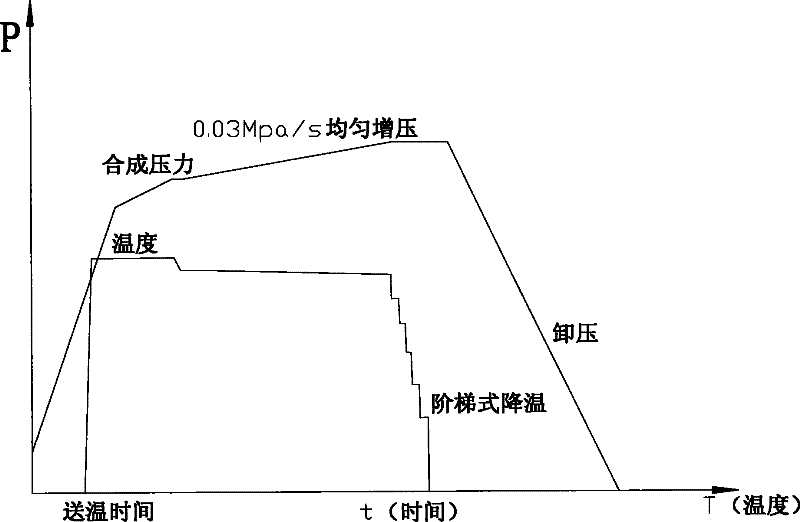

[0024] Diamond synthesis process, the steps are: (1) Put the synthetic block of pyrophyllite into the high-pressure chamber of the six-sided press, and push the six pistons of the six-sided press forward under the action of the booster pump to make the six-sided press The six cemented carbide tops of the press are filled with liquid and pressurized. After the pressure reaches 6MPa, the six-sided top press is connected to overpressure to 65MPa, and the pressure increase speed is controlled to 0.1Mpa / s during the process of increasing from normal pressure to 65MPa; Hold the pressure for 8 minutes, then pressurize to a synthesis pressure of 80MPa in 20 seconds, in order to fully melt the graphite column (graphite powder and metal catalyst powder) in the synthesis cavity of the pyrophyllite synthesis block, so that the graphite is fully converted; increase from normal pressure to 80MPa When the pressure is 40MPa during the pressurization process, start heating to prevent pyrophylli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com