Method for separating dichlorophenol mixture by cross-current dissociation extraction

A dichlorophenol and mixture technology, applied in the field of chemical separation of mixed dichlorophenol, can solve the problems of high equipment requirements, difficult separation, low product yield, etc., and achieve simple process and equipment, low production cost and high product quality. The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

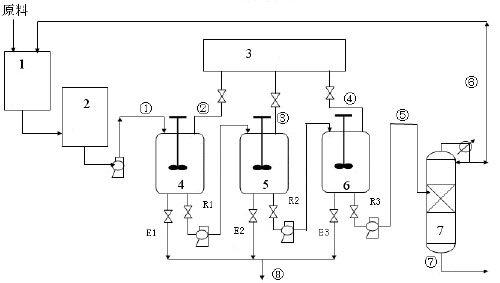

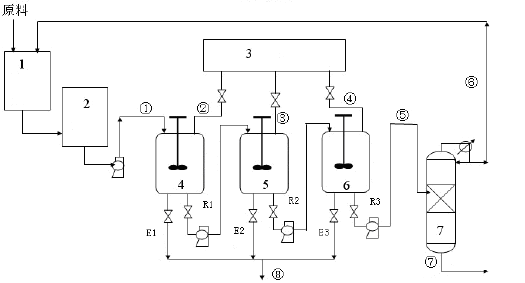

[0019] Cross-flow dissociation extraction method for separating dichlorophenol mixture, refer to figure 1 Shown technological process and process parameter shown in table 1, 2, in raw material batching kettle 1, 30g raw material thick dichlorophenol (in terms of mass percent, containing 2,4-dichlorophenol 89%, 2,6-dichlorophenol Phenol 6%, 2,4,6-trichlorophenol 5%) and 100mL organic solvent tetrachlorethylene are made into raw material solution and enter raw material solution storage tank 2, prepare sodium hydroxide aqueous solution 45mL simultaneously (internal dissolved solid sodium hydroxide 1.5g) and enter the lye storage tank 3, the first time 20mL lye ( figure 1 The middle stream ②) is added to the extraction kettle 4 of I, and all the raw materials are added ( figure 1 Middle stream ①), stirring at room temperature, stirring shaft speed 150 rpm, stirring for about 10 minutes, standing still for about 20 minutes, taking out the organic layer R1 (lower layer) and water l...

Embodiment 2

[0027] Substantially the same as Example 1, but the tetrachlorethylene consumption is changed into 80mL.

Embodiment 3

[0029] Substantially the same as Example 1, but the tetrachlorethylene consumption is changed into 120mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com