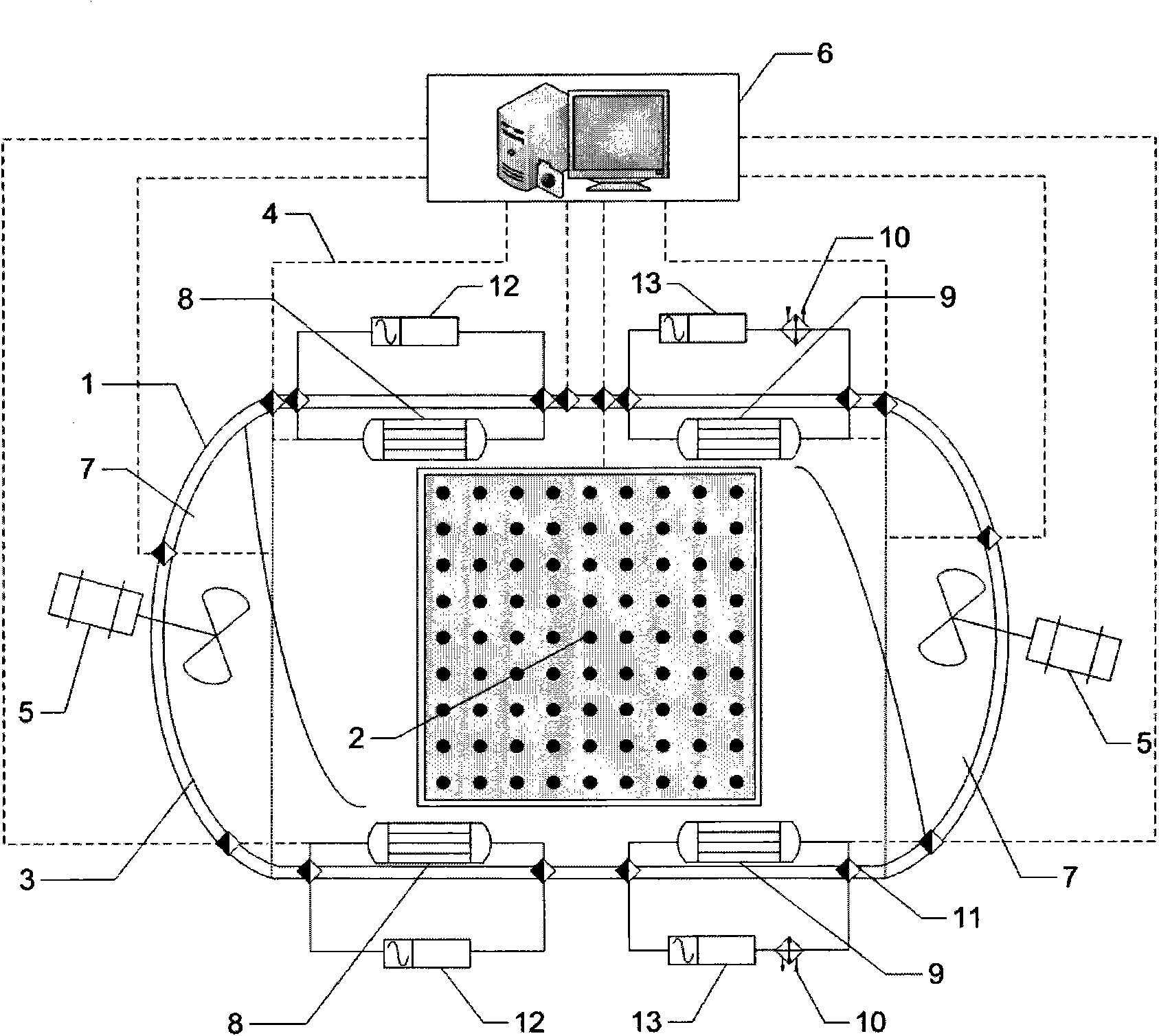

Method and device for simulating formation temperature in multi-element thermal fluid injected oil extraction three-dimensional simulation test

A multi-component thermal fluid and formation temperature technology, which is applied in the fields of production fluids, earthwork drilling, wellbore/well components, etc. The effect of fast cooling process, high degree of automation and compact system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

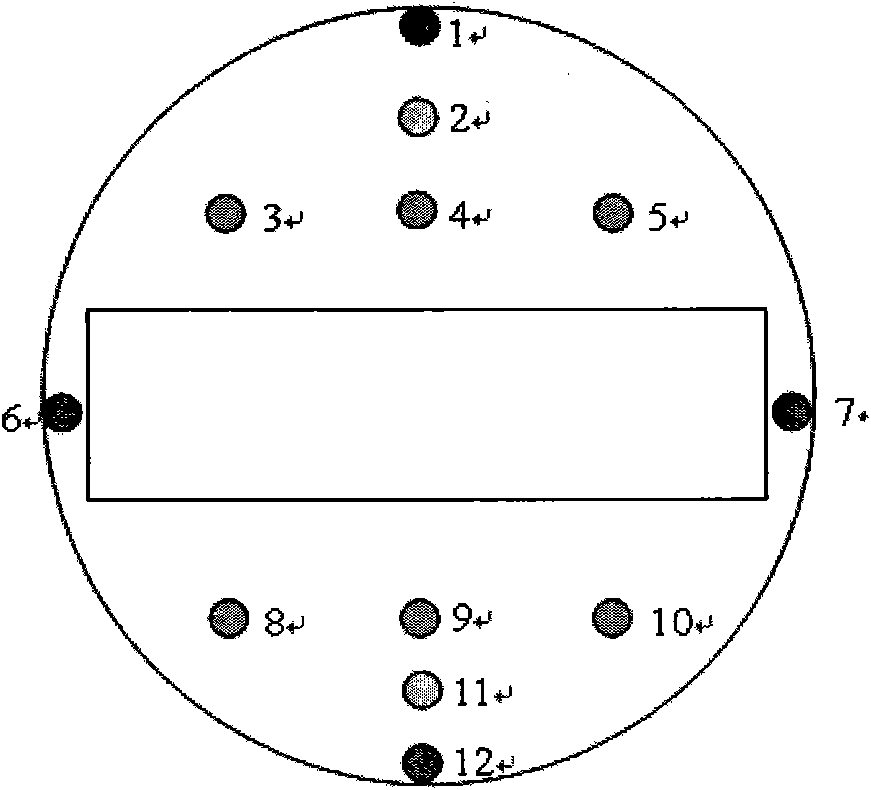

Method used

Image

Examples

Embodiment 1

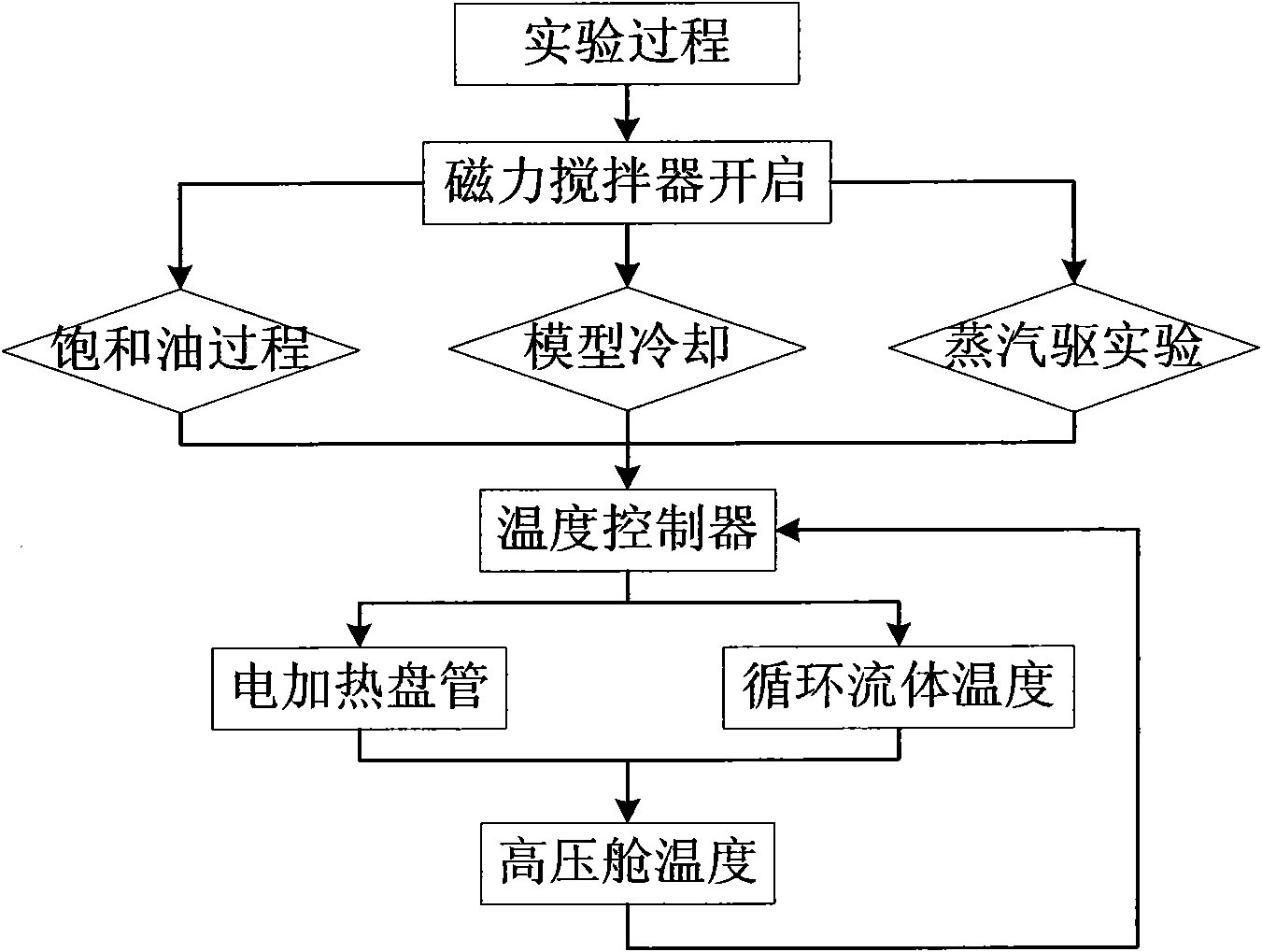

[0066] In an embodiment according to the present invention, the experimental operating pressure is 2MPa, and the power of the electric heating coil is 5KW.

[0067] Saturated oil process:

[0068] 1. Turn on the magnetic stirrer 5;

[0069] 2. Turn on the temperature controller 12, and set the control temperature to 80°C;

[0070] 3. The confining pressure gas in the hyperbaric chamber is heated by the electric heating coil under normal pressure until it reaches 80°C;

[0071] 4. Start the normal-pressure saturated oil process. During this process, the setting of the temperature controller remains unchanged, and the electric heating coil maintains the temperature of the high-pressure chamber at 80°C; (heavy oil has a high viscosity, and it can only have certain fluidity under higher temperature conditions )

[0072] 5. Start the process of pressurizing saturated oil, and the confining pressure gas in the hyperbaric chamber is continuously filled, and the electric heating co...

Embodiment 2

[0085] In an embodiment according to the present invention, the experimental operating pressure is 20MPa, and the power of the electric heating coil is 20KW.

[0086] Saturated oil process:

[0087] 1. Turn on the magnetic stirrer 5;

[0088] 2. Turn on the temperature controller 12, and set the control temperature to 90°C;

[0089] 3. The confining pressure gas in the hyperbaric chamber is heated by the electric heating coil under normal pressure until it reaches 90°C;

[0090] 4. Start the normal-pressure saturated oil process. During this process, the setting of the temperature controller remains unchanged, and the electric heating coil maintains the temperature of the high-pressure chamber at 90°C; (heavy oil has a high viscosity, and can only have certain fluidity under higher temperature conditions )

[0091] 5. Start the process of pressurizing the saturated oil, the confining pressure gas in the hyperbaric chamber is continuously filled, and the electric heating coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com