Surface acoustic wave resonant pressure sensor

A pressure sensor, surface acoustic wave technology, applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, instruments, etc., can solve the problems of low stability, poor reliability, low precision, etc., to improve repeatability and shorten lead wires , the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

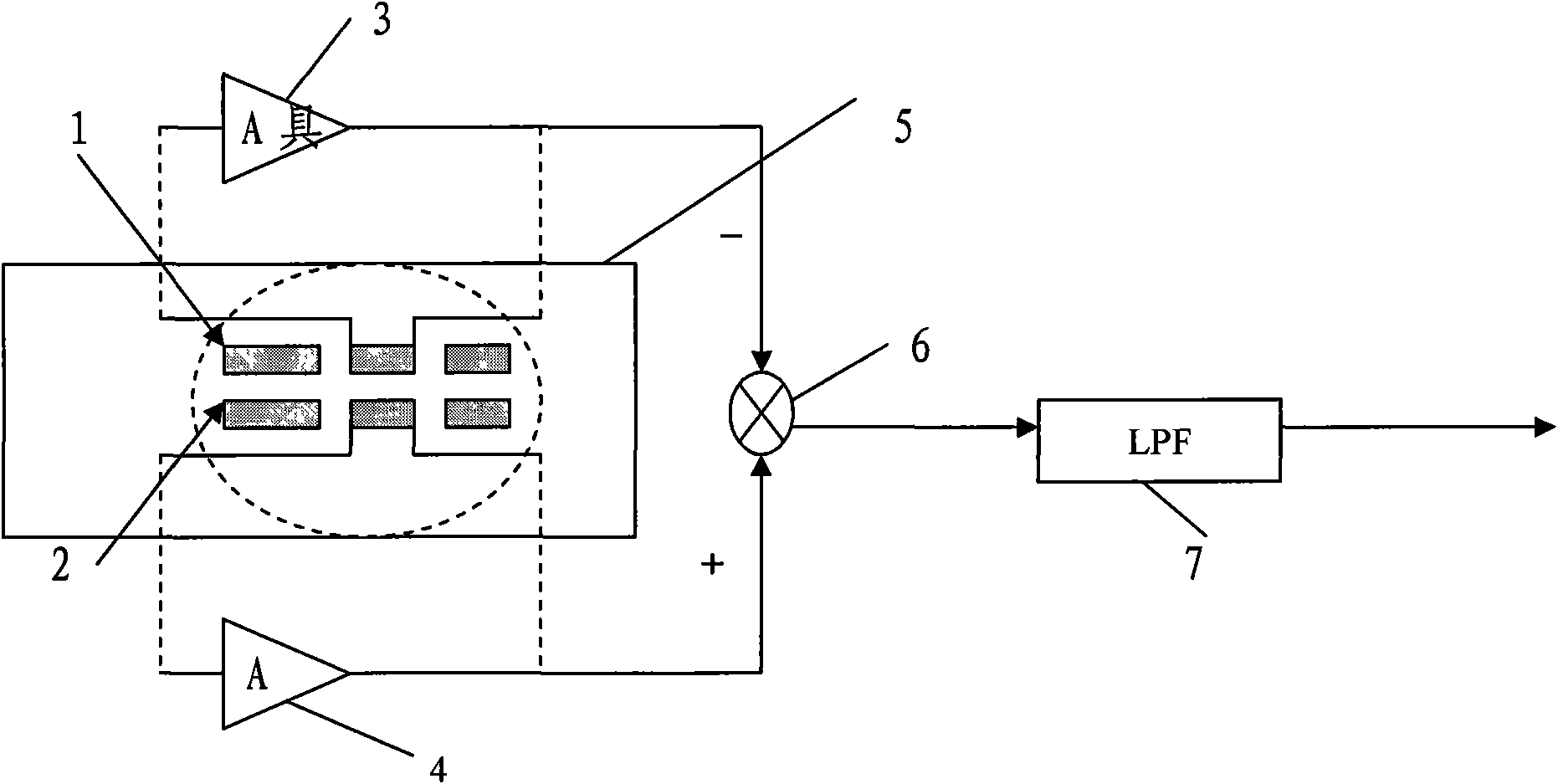

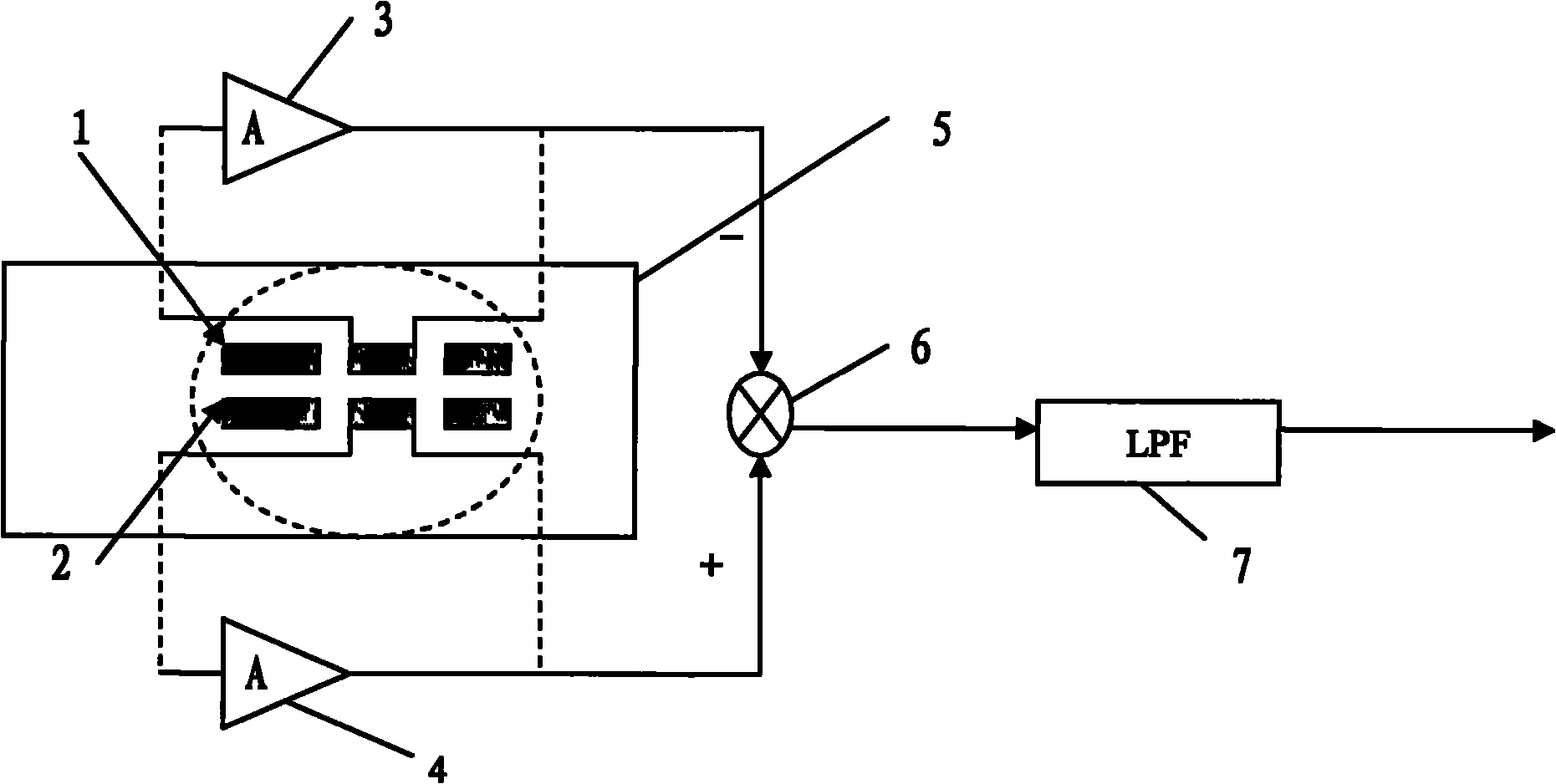

[0016] Sensor embodiment: reference figure 1 The system composition of the specific implementation of the surface acoustic wave resonant pressure sensor proposed by the present invention is as described above, including resonators 1 and 2, low-noise monolithic integrated amplifiers 3 and 4, and the two resonators are respectively connected to the amplifier In the feedback loop, an oscillator with a certain output frequency is formed, the interdigital transducer 5, the double-balanced mixer 6, and the LC low-pass filter 7. The frequencies of the two outputs are mixed, low-pass filtered and amplified to obtain A difference frequency output corresponding to the applied pressure one by one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com