Manufacturing method of shallow trench isolation structure

A technology of isolation structure and manufacturing method, which is applied in the field of manufacturing shallow trench isolation structures, can solve problems such as repeated operations, achieve the effects of repairing damaged substrates, saving manufacturing costs, and ensuring product yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The simple grinding liquid supply system of the present invention will be further described in detail below with reference to the drawings and specific embodiments.

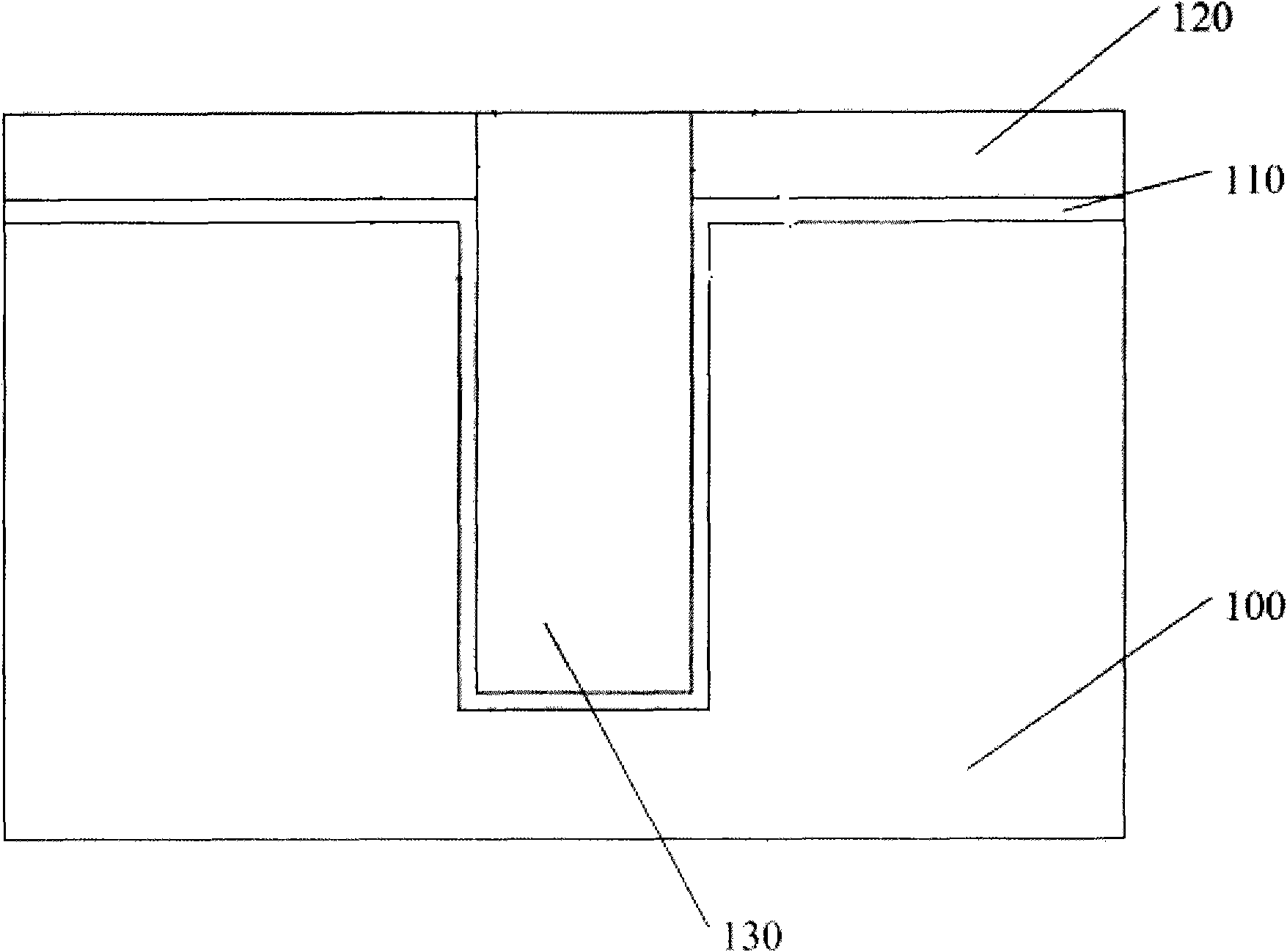

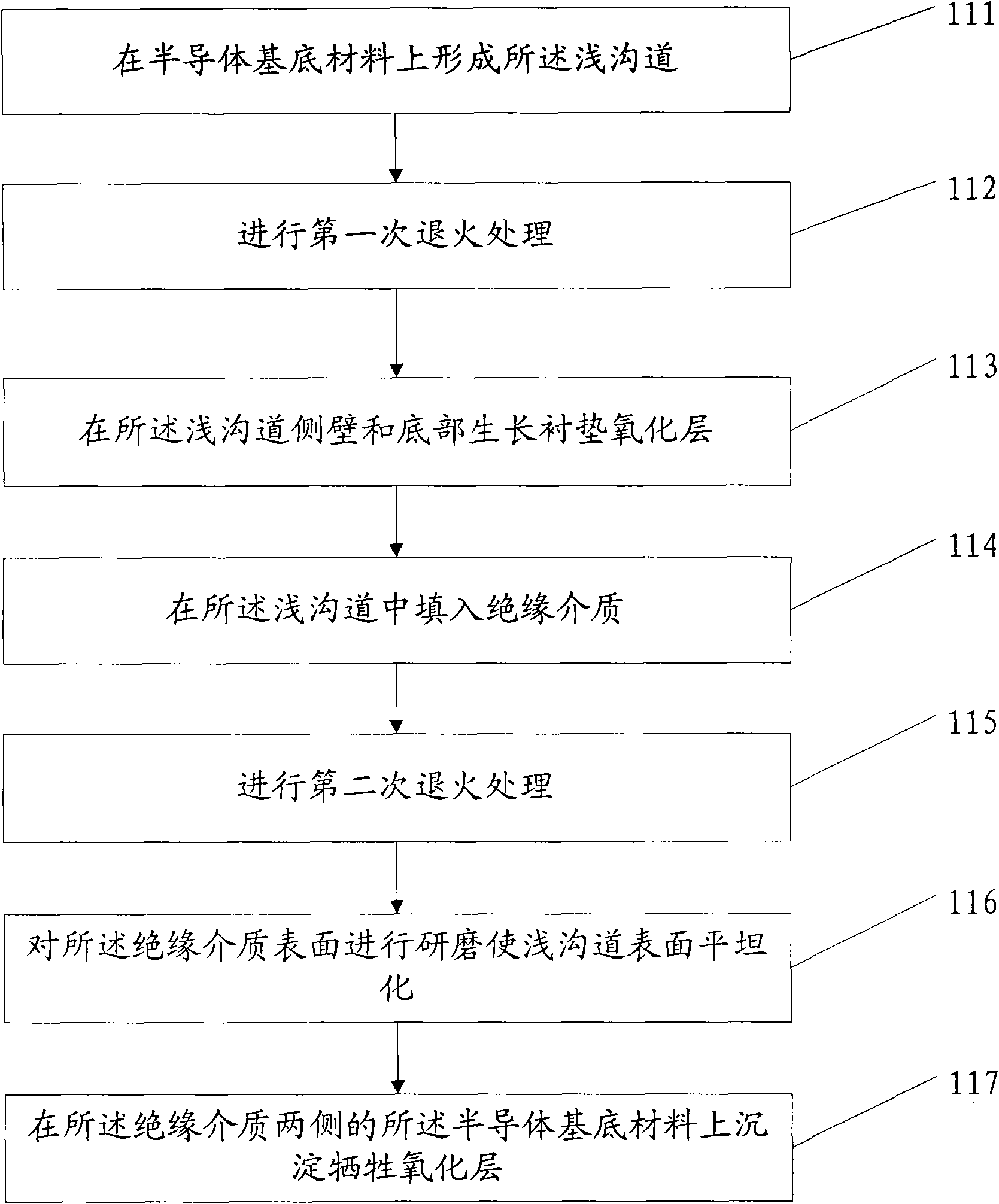

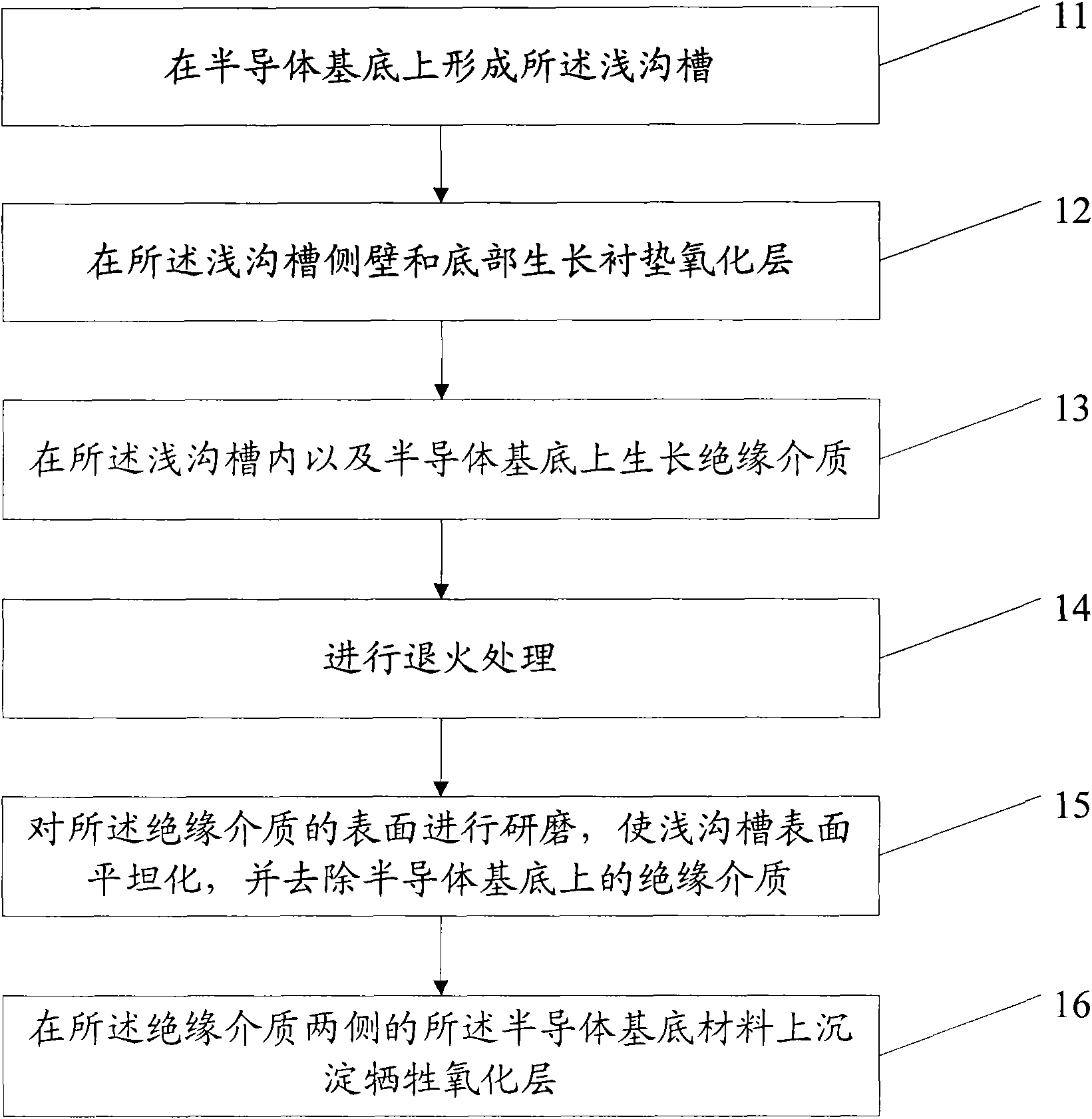

[0023] First please refer to image 3 , image 3 It is a flow chart of the first embodiment of the present invention. It can be seen from the figure that the first embodiment includes the following steps: Step 11: forming the shallow trench on the semiconductor base material, the semiconductor base material is silicon, and the The general shape of the shallow trench can be referred to figure 1 , form shallow trench isolation, generally use silicon nitride as a hard mask, define a steep trench on the semiconductor substrate with anisotropy (anisotropy) etching method (dry etching); step 12: in the shallow trench The pad oxide layer is grown on the side wall and the bottom. The purpose of growing the pad oxide layer is to avoid the corner effect (Corner Effect). If the corner of the shallow trench is too s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com