Method for preparing cobalt-doped zinc oxide (CoxZn1-xO) multifunctional magnetic nano powder by alcohol heating process

A technology of coxzn1-xo and magnetic nanometers, which is applied in the field of preparation of cobalt-doped zinc oxide multifunctional magnetic nanopowders by alcohol thermal method, can solve the problems of small nanopowder particles, difficulty in photocatalyst recycling, etc. Excellent room temperature ferromagnetism and photocatalytic properties, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

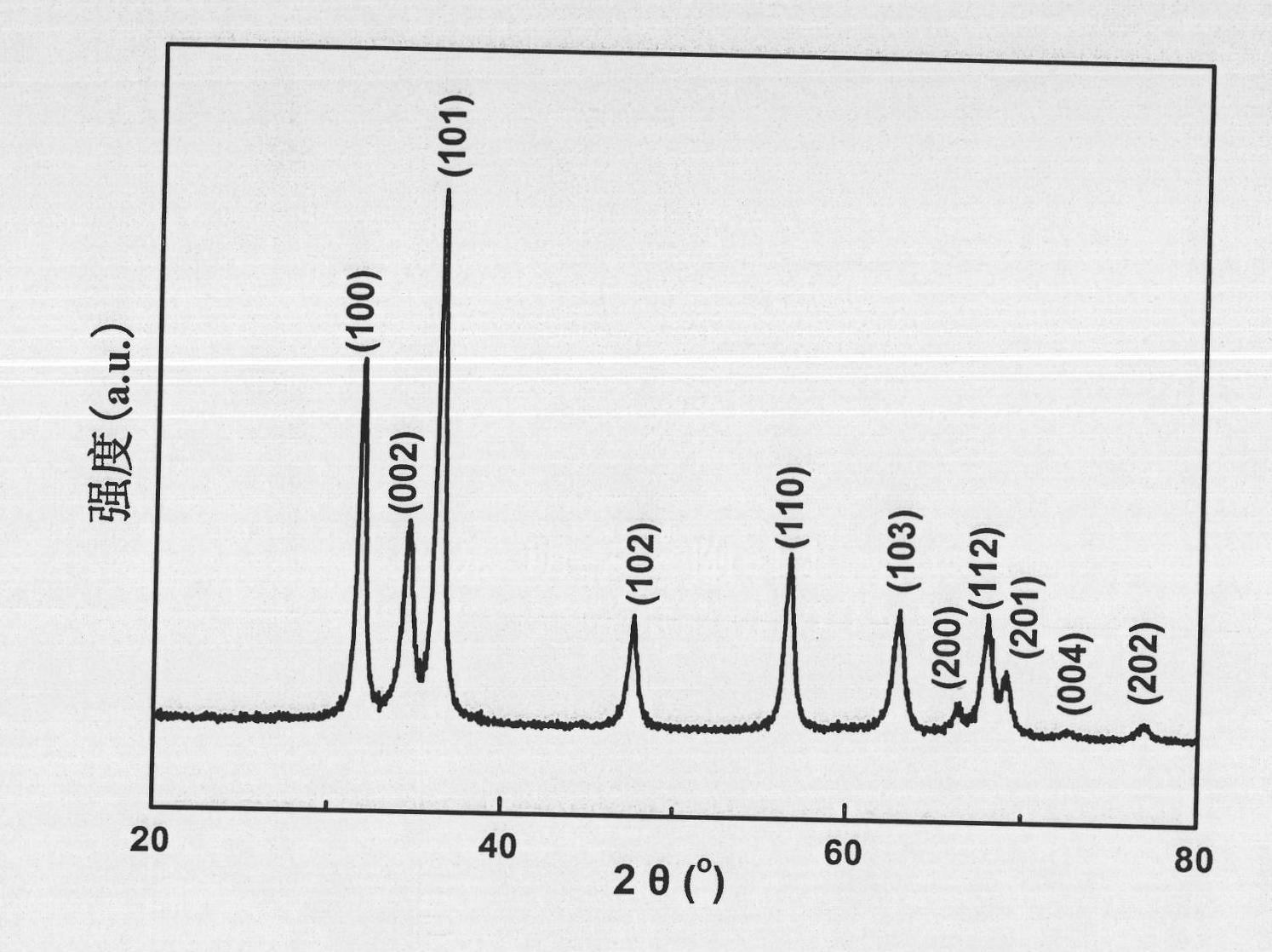

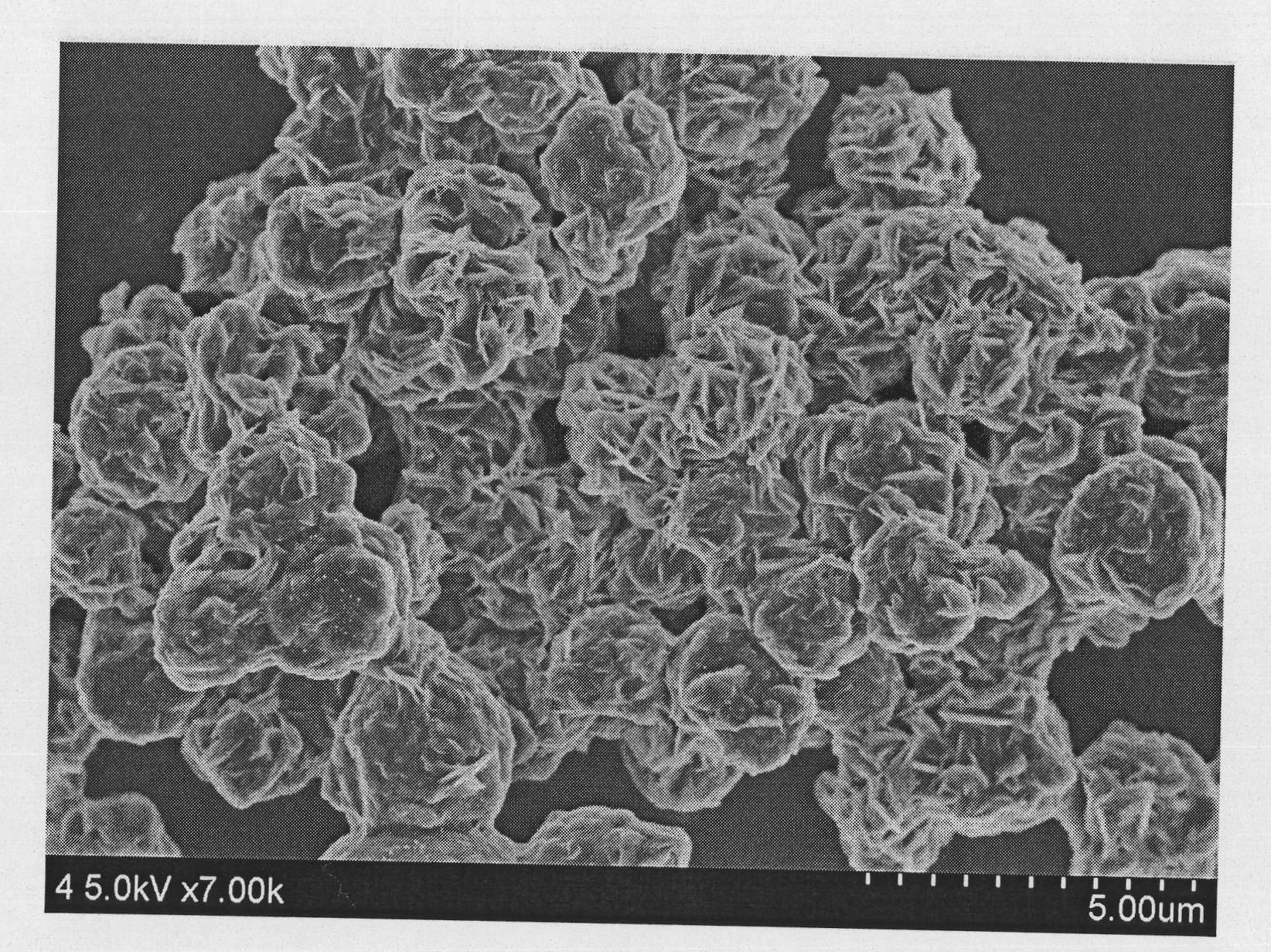

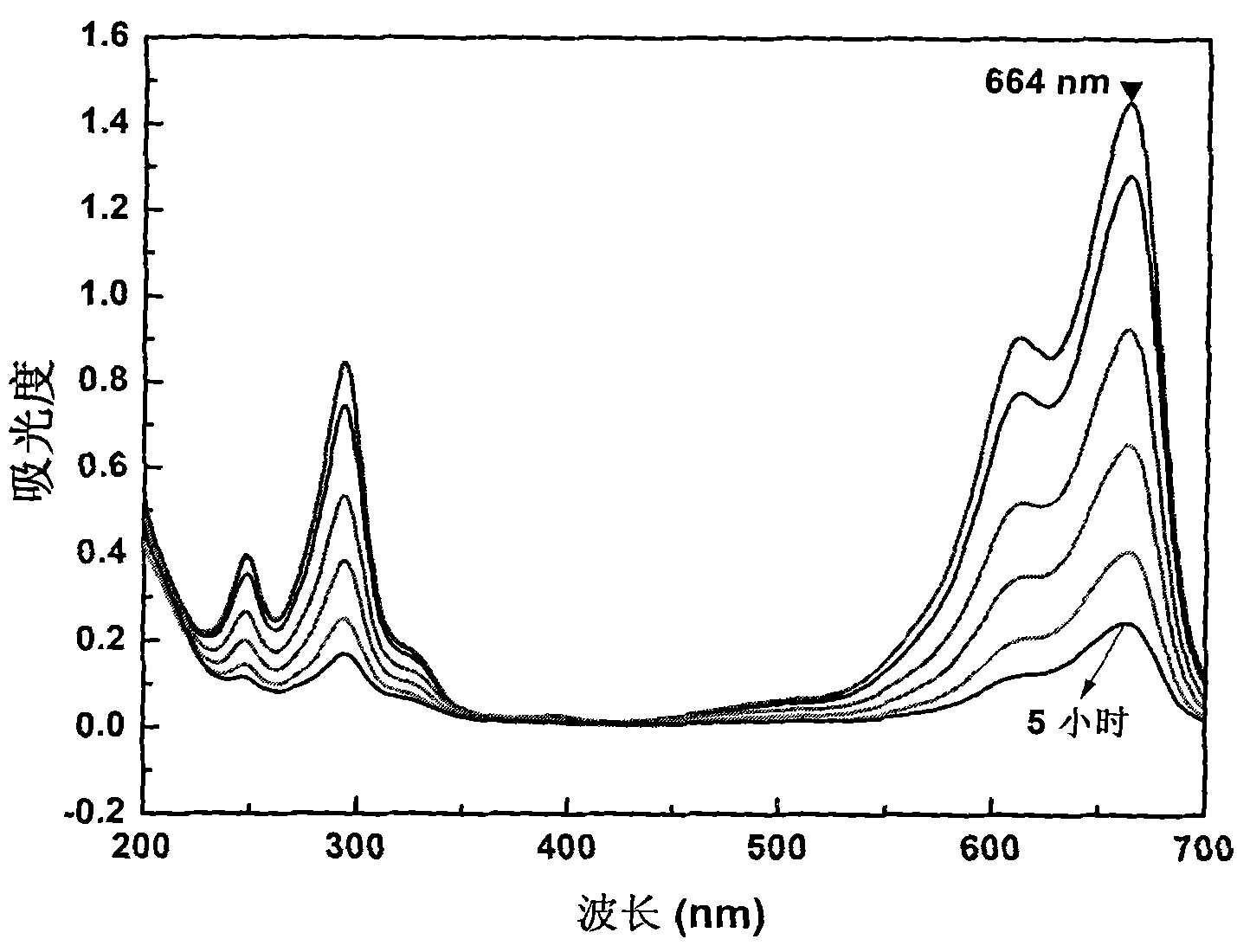

[0043] At room temperature, weigh 1.0412g Zn(NO 3 ) 2 ·6H 2 O(0.0035mol), 0.4365g Co(NO 3 ) 2 ·6H 2 O (0.0015mol), measure 55ml of ethylene glycol and put it into a three-necked flask, mechanically stir at a speed of 500rpm for 20 minutes, then add 3.6g of anhydrous sodium acetate and 1.1ml of polyethylene glycol-200 for ultrasonic dispersion for 40 minutes, and wait for complete After dissolving and dispersing evenly, pour the above solution into the reaction kettle, raise the temperature to 200° C., and react for 12 hours. After the reaction was completed, it was naturally cooled to room temperature, centrifuged at 7000rpm for 10 minutes to obtain the product; the product was washed with deionized water 4 times and absolute ethanol twice, and then dried at 50°C for 6 hours to obtain Co 0.3 Zn 0.7 O multifunctional magnetic nano powder. figure 1 This is the X-ray diffraction pattern of the product synthesized in this example, and compared with the standard XRD pattern,...

Embodiment 2

[0045] At room temperature, weigh 0.8766g Zn(CH 3 COO) 2 2H 2 O(0.004mol), 0.2491g Co(CH 3 COO) 2 4H 2 O (0.001mol), measure 60ml of ethylene glycol into a three-necked flask, mechanically stir at 600rpm for 40 minutes, then add 3g of anhydrous sodium acetate, 1.2ml of polyethylene glycol-200 and ultrasonically disperse for 60 minutes, until completely dissolved After uniform dispersion, the above solution was poured into the reaction kettle, the temperature was raised to 180° C., and the reaction was carried out for 14 hours. After the reaction was completed, it was naturally cooled to room temperature, and centrifuged at 6000rpm for 20 minutes to obtain the product; the product was washed with deionized water and absolute ethanol three times, and then dried at 60°C for 5 hours to obtain Co 0.2 Zn 0.8 O multifunctional magnetic nano powder. Figure 4 This is the X-ray diffraction pattern of the product synthesized in this example, and compared with the standard XRD pat...

Embodiment 3

[0047] At room temperature, weigh 0.6133g ZnCl 2 (0.0045mol), 0.1189g CoCl 2 ·6H 2 O (0.0005mol), measure 45ml of ethylene glycol into a three-necked flask, mechanically stir at 700rpm for 30 minutes, then add 4g of anhydrous sodium acetate, 1ml of polyethylene glycol-200 and ultrasonically disperse for 30 minutes, until completely dissolved and dispersed After uniformity, the above solution was poured into the reaction kettle, the temperature was raised to 200°C, and the reaction was carried out for 10 hours. After the reaction was completed, it was naturally cooled to room temperature and centrifuged at 8000 rpm for 5 minutes to obtain the product; the product was washed 6 times with deionized water and 1 time with absolute ethanol, and then dried at 40°C for 12 hours to obtain Co 0.1 Zn 0.9 O multifunctional magnetic nano powder. Image 6 This is the X-ray diffraction pattern of the product synthesized in this example, and compared with the standard XRD pattern, it show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com