New multifunctional inorganic material capable of turning desert into oasis

A multi-functional, new material technology, applied in the field of desertification control, can solve the problems of difficult to use effect, high cost, single function, etc., and achieve the effect of small investment, quick effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

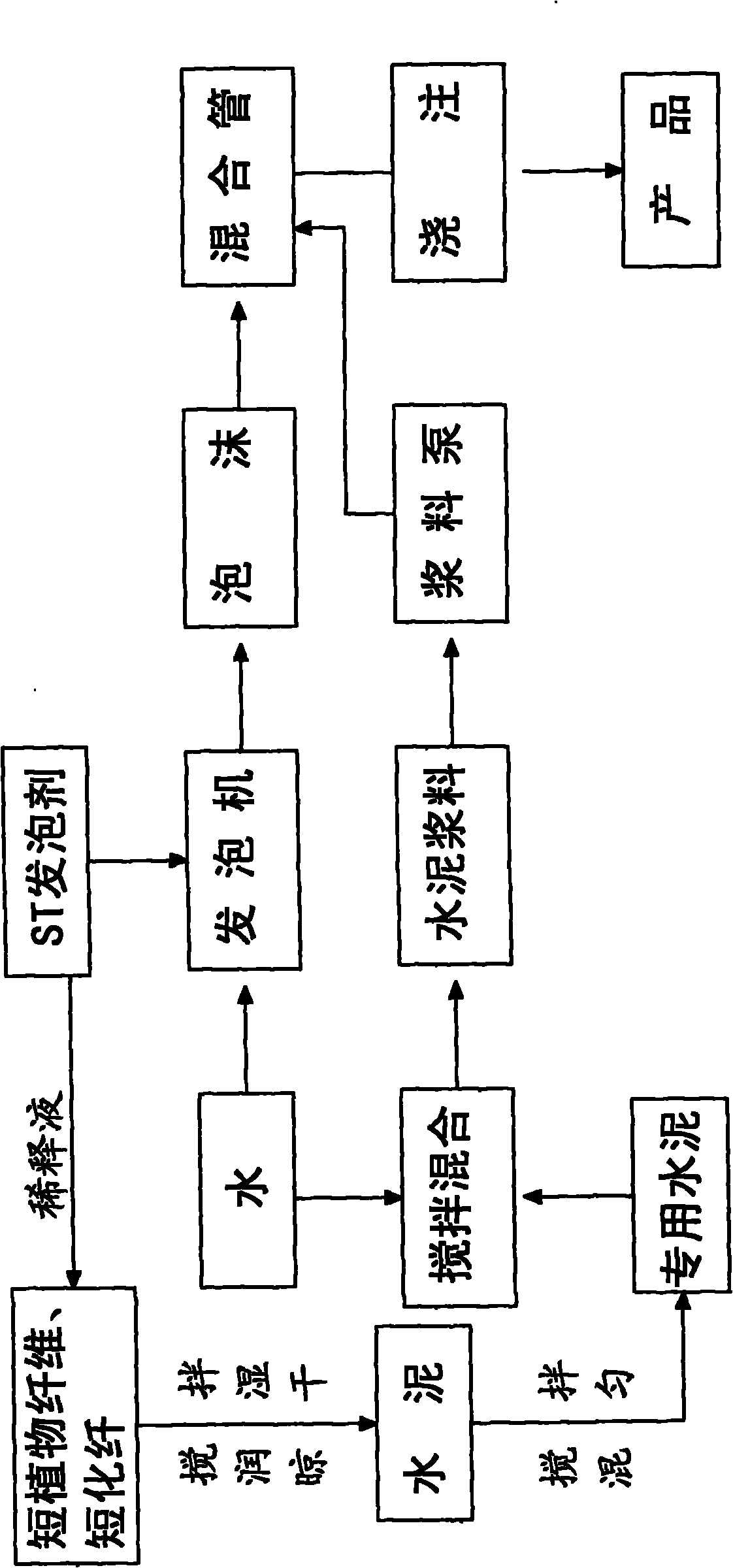

Method used

Image

Examples

Embodiment 1

[0041] Control the windward slope of the desert, slope = 12°, 2m 3 Product, laying thickness 50mm.

[0042] 1. Plant fibers and chemical fibers are selected according to the ratio of plant fibers: chemical fibers = 0.5, and the total mass of the two accounts for 0.3% of the cement mass.

[0043] 2. Put the selected short fibers in the 40-fold dilution of ST foaming agent, stir to make the short fibers all wet, take them out, and dry them for later use.

[0044] 3. Take label = 32.5 #700kg of cement, add the short fiber of the 2nd step gain in proportion, with " mace shape " stirring paddle, stir with the speed of 1450 revs / min, make material mix uniformly, obtain special cement of the present invention, enter next step.

[0045] 4. Add the special cement of the present invention into the mixing tank of the pulping machine, add 0.6 times the water of the cement quality, after stirring and mixing, transfer it to the concrete tank of the concrete mixing tank truck, send it to t...

Embodiment 2

[0056] Treatment of desert leeward slope, slope = 15°, 2m 3 Product, laying thickness 25mm.

[0057] 1. Plant fiber and chemical fiber are selected according to the ratio of plant fiber:chemical fiber=0.2~0.8 (mass, the same below), and the total mass of the two accounts for 0.2% of the cement mass.

[0058] 2. Put the selected short fibers in the 30-fold dilution of ST foaming agent, stir to make the short fibers all wet, take them out, and dry them for later use.

[0059] 3. Take label = 42.5 # Cement 500kg, add the short fiber of the 2nd step gained in proportion, with " mace shape " stirring paddle, stir with the speed of 1450 revs / min, make material mix homogeneously, obtain special cement of the present invention, enter next step.

[0060] 4. Add the special cement of the present invention into the mixing tank of the pulping machine, add water of 0.65 times the cement quality, after stirring and mixing, transfer it to the concrete tank of the concrete mixing tank truck...

Embodiment 3

[0070] Control rocky desertification barren hills. The slope is 30-60°, and the average thickness of 100m3 products is 25mm. Climate conditions: no rain within 24 hours after rain (or sunny day, temperature between 5-25°C).

[0071] 1. Plant fibers and chemical fibers are selected according to the ratio of plant fibers: chemical fibers=0.8 (mass, the same below), and the total mass of the two accounts for 0.4% of the cement mass.

[0072] 2. Put the selected short fibers in the 20-fold dilution of ST foaming agent, stir to make the short fibers all wet, take them out, and dry them for later use.

[0073] 3. Take label = 42.5 # According to the throughput capacity of the equipment, add the short fibers obtained in the second step in batches in proportion, and use a "mace-shaped" stirring paddle to stir at a speed of 1450 rpm to make the materials evenly mixed, and the product is obtained. Invent special cement and enter the next step.

[0074] 4. Add the special cement of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com