Method for producing superfine talcum powder by adopting mixed grinding technology

A technology of ultra-fine talc powder and mixed grinding, which is applied in chemical instruments and methods, inorganic pigment treatment, dyeing physical treatment, etc. It can solve the problems of reducing production costs, talc powder structure changes, and poor particle uniformity, so as to improve mechanical properties. , Narrow particle size distribution and low degree of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

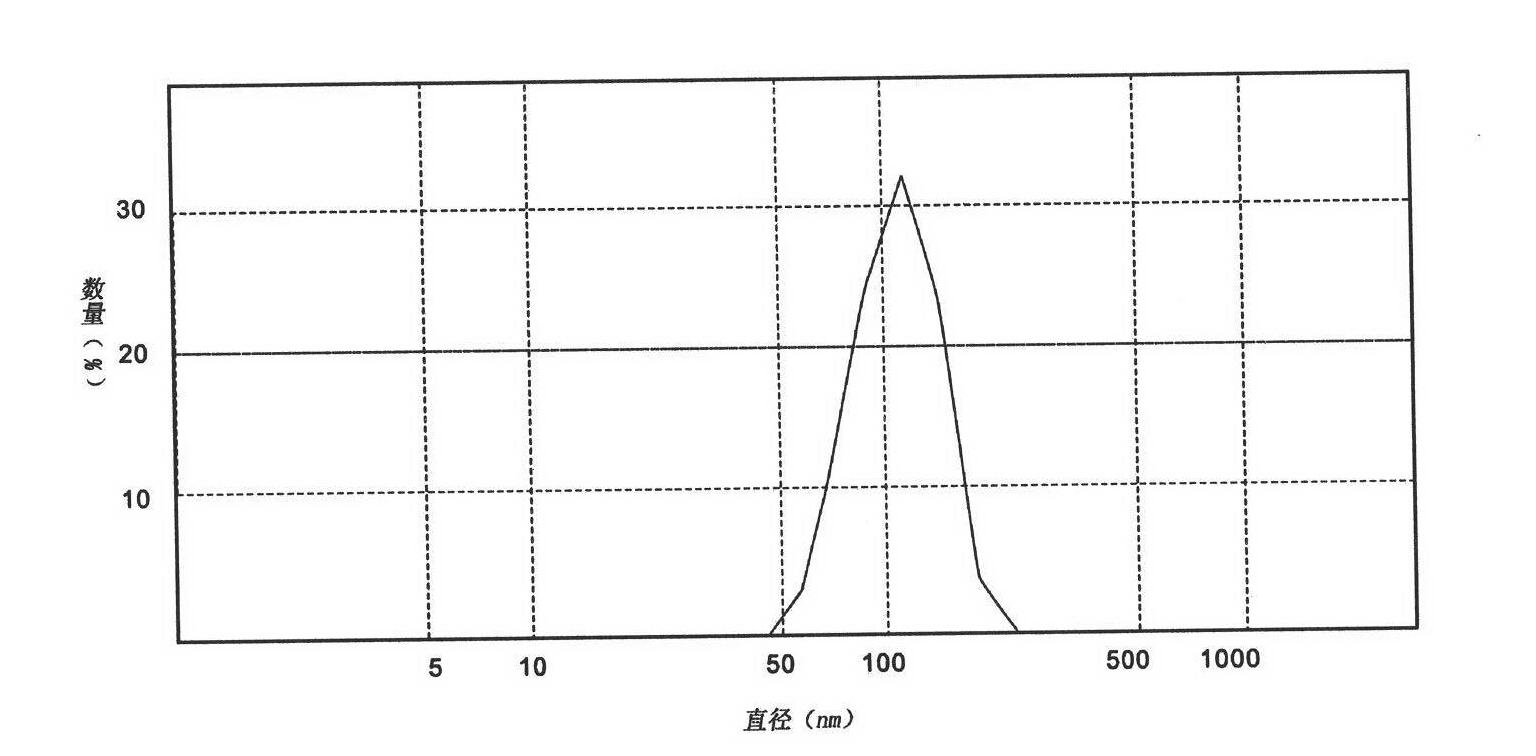

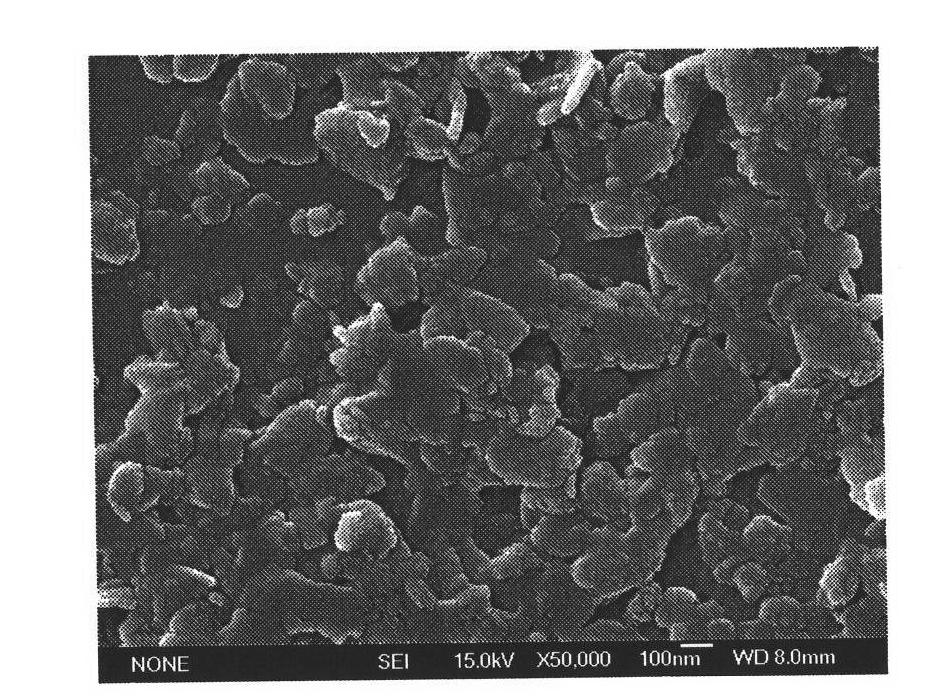

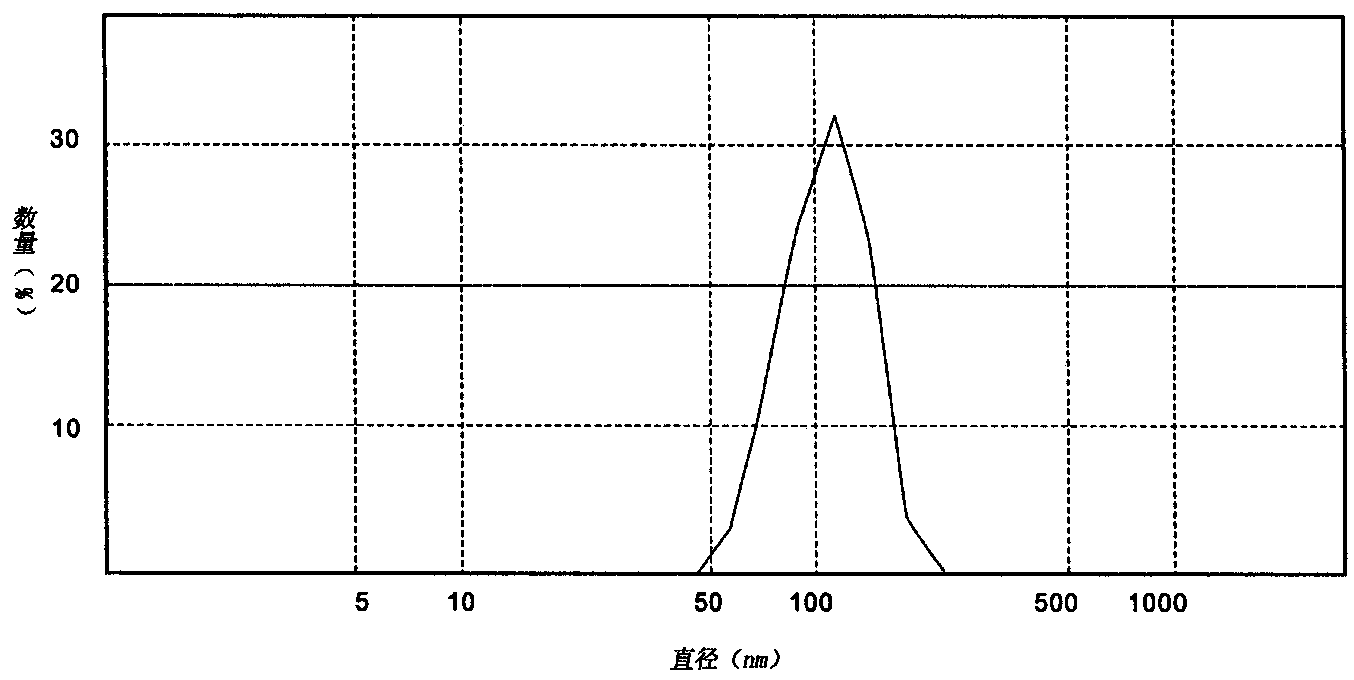

[0023] Weigh 40g of talcum powder with a fineness of 1250 mesh, mix it evenly with 800g of zirconia microspheres with a diameter of 0.1-0.2mm, and then add it to the grinding container of the sand mill. The effective volume of the grinding container is 750mL. The linear speed of the sand mill is 4.7m / s, and the dry grinding is carried out, and the grinding time is 30min; then 160g of deionized water is added, and the linear speed of the sand mill is adjusted to 12.6m / s, and the wet grinding is carried out, and the grinding time is 25min. After grinding, the obtained slurry is filtered, spray-dried and air-jet pulverized to obtain an ultrafine talc powder with an average particle size of 367.4 nm.

Embodiment 2

[0025] Weigh 40g of talcum powder with a fineness of 1250 mesh, mix it evenly with 800g of zirconia microspheres with a diameter of 0.1-0.2mm, and then add it to the grinding container of the sand mill. The effective volume of the grinding container is 750mL. The linear speed of the sand mill is 6.3m / s, and the dry grinding is carried out, and the grinding time is 30min; then 160g of deionized water is added, and the linear speed of the sand mill is adjusted to 12.6m / s, and the wet grinding is carried out, and the grinding time is 25min. After the grinding is finished, the obtained slurry is filtered, spray-dried and air-jet pulverized to obtain an ultrafine talc powder with an average particle diameter of 293.2 nm.

Embodiment 3

[0027] Weigh 40g of talcum powder with a fineness of 1250 mesh, mix it evenly with 800g of zirconia microspheres with a diameter of 0.1-0.2mm, and then add it to the grinding container of the sand mill. The effective volume of the grinding container is 750mL. The linear speed of the sand mill is 7.9m / s, and the dry grinding is carried out, and the grinding time is 30min; then 160g of deionized water is added, and the linear speed of the sand mill is adjusted to 12.6m / s, and the wet grinding is carried out, and the grinding time is 25min. After the grinding is finished, the obtained slurry is filtered, spray-dried and air-jet pulverized to obtain an ultrafine talc powder with an average particle diameter of 421.1 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com