Method for producing sulfur through separation, vulcanization and hydrogen oxidation of circling foam

A foam separation and hydrogen sulfide technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of low sulfur content, increased energy consumption, loss of desulfurization agent, and unsatisfactory separation effect, and achieve desulfurization liquid. Low entrainment, low energy and agent consumption, and low filtrate volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

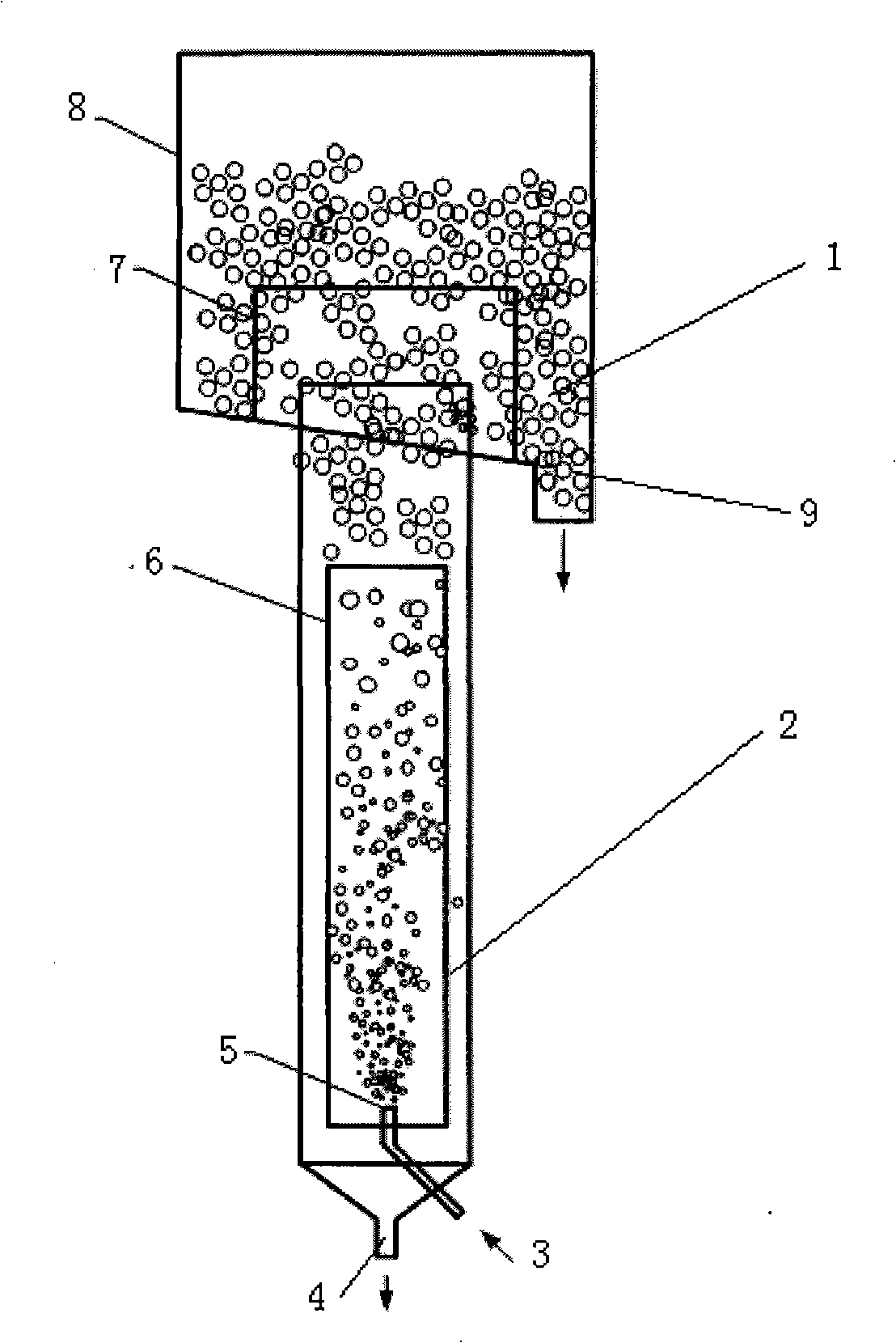

[0020] The loop foam separation tower is composed of a bubbling section 2 and a foam collection section 1. The bubbling section 1 is an airlift inner loop reactor, including a reactor guide tube 6 and a gas distributor 5; the foam collection section 1 is an overflow The trough-type gas-liquid separator is provided with an overflow weir 7 . The diameter ratio of the bubbling section and the foam collection section is 1:1.4~1:1.7, and the height ratio is 1:0.5~1:0.9; the diameter ratio of the overflow tank weir and the foam collection section of the foam collection section is 1:1~1 :1.4, the height ratio is 0.1:1~0.3:1.

[0021] Continuous operation: the surfactant and the solution containing sulfur particles are mixed and then pumped into the circulation foam separation tower, and the air is blown into the circulation reactor guide tube of the bubbling section 2 in the tower through the air inlet pipe 3 and the gas distributor 5 at the bottom of the tower In 6, a stable foam i...

Embodiment 1

[0024] The present embodiment adopts the continuous operation mode, and the circulation foam separates H 2 Sulfur particles obtained by oxidation of S. The average particle size of the sulfur particles is 21 μm, and when the pH is 8-10, the surface potential of the sulfur particles is 10-1 mV. The bubble section of the circulating foam separation tower has a diameter of 170mm and a height of 1300mm. The foam collection section has a diameter of 290mm and a height of 660mm, and the overflow weir has a diameter of 228mm and a height of 100mm. Continuous operation is adopted. After the surfactant SDBS is mixed with the solution containing sulfur particles, it is pumped in from the bottom of the separation tower. After the foam is enriched, it is discharged from the bottom of the foam collection section. After the sulfur is filtered, the filtrate is merged into the desulfurization solution to be separated, and the sulfur is dried and recovered. . The desulfurization solution af...

Embodiment 2

[0026] The present embodiment adopts the batch mode of operation, and the circulating foam separates H 2 Sulfur particles obtained by oxidation of S. The properties of the sulfur granules are the same as in Example 1. The structure of the bubbling section of the circulating foam separation tower is the same as in Example 1, the diameter of the foam collecting section is 240mm, the height is 1000mm, and the overflow weir is 240mm high. The solution containing sulfur particles (with a content of 2g / L) is added to the circulation foam separation device at one time, and the liquid volume in the separation tower is controlled to be 27-30L. Surfactant SDS is fed into the circulating foam separation device at a certain rate to ensure that the content of surfactant is 0.12g per desulfurization solution containing 1g of sulfur particles, and the superficial velocity of air is 1.0cm / s. After 20 minutes of stable operation under the above conditions, the separation rate of sulfur parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface potential | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com