Solar-thermal power generation steam heat receiver control and equipment protection method and system

A technology for solar thermal power generation and control methods, which is applied in control systems, lighting and heating equipment, steam generation, etc., can solve problems such as operation and control methods are not involved, and achieve improved control quality, small heat absorption area, and great difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

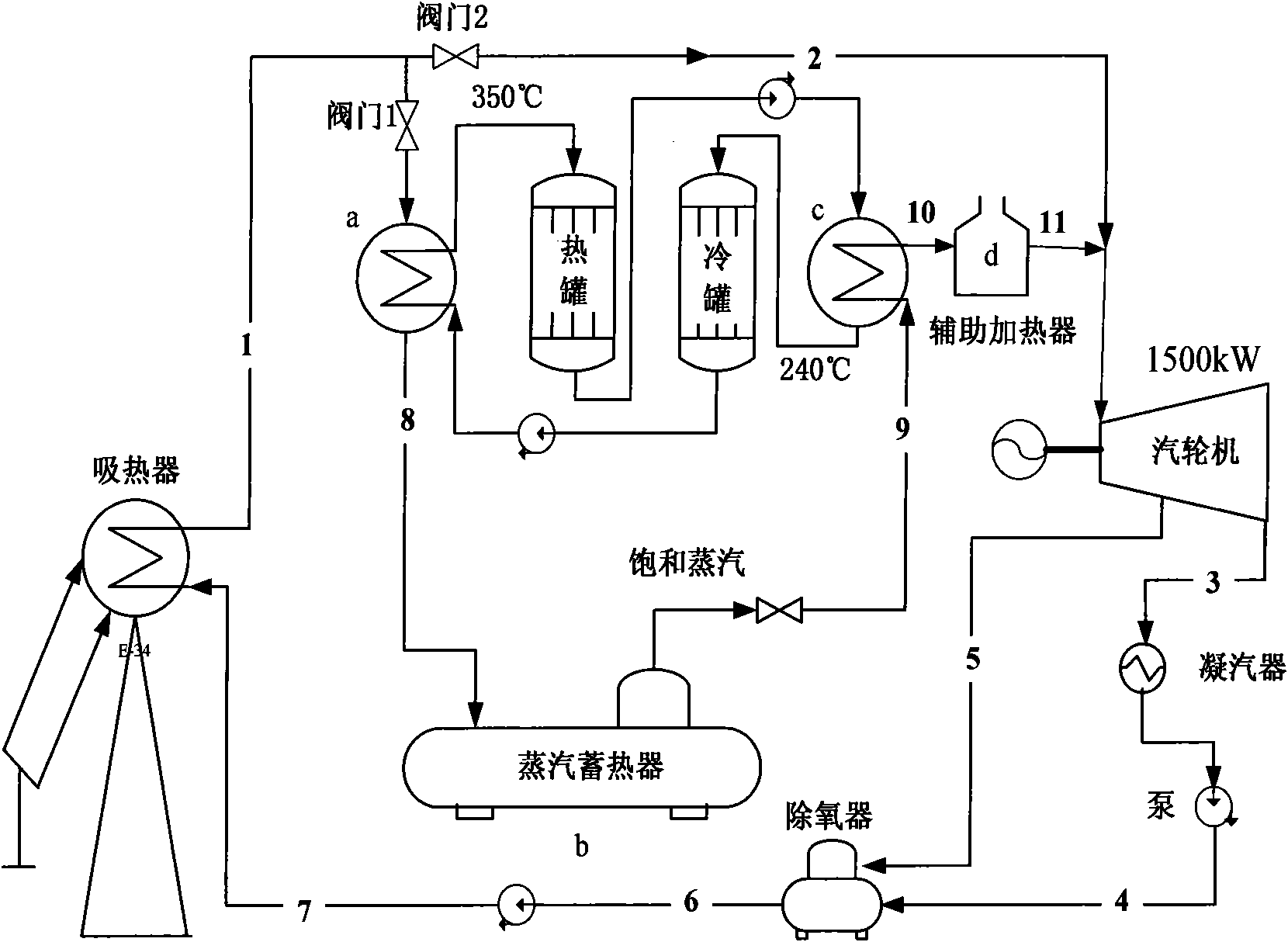

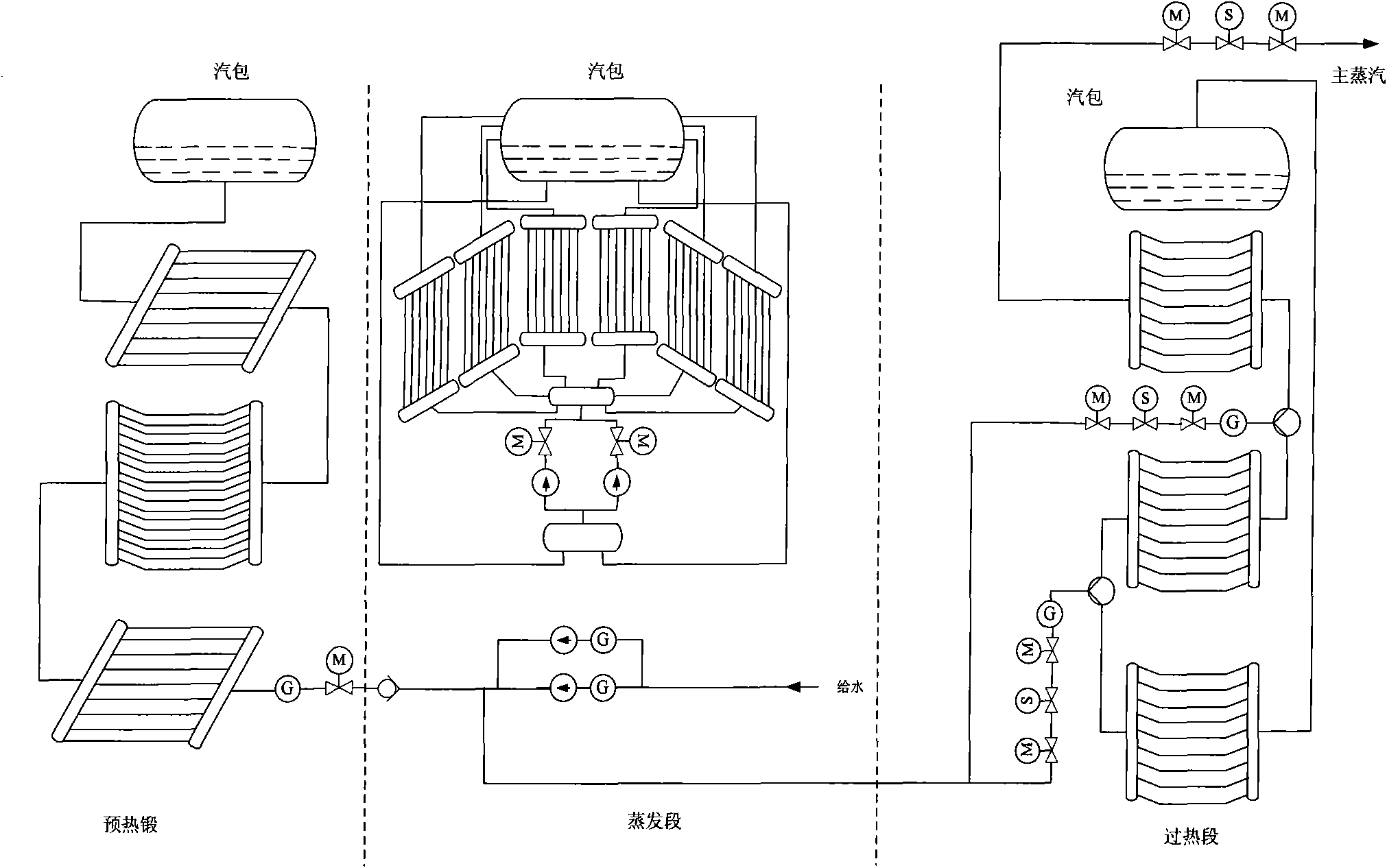

Method used

Image

Examples

Embodiment Construction

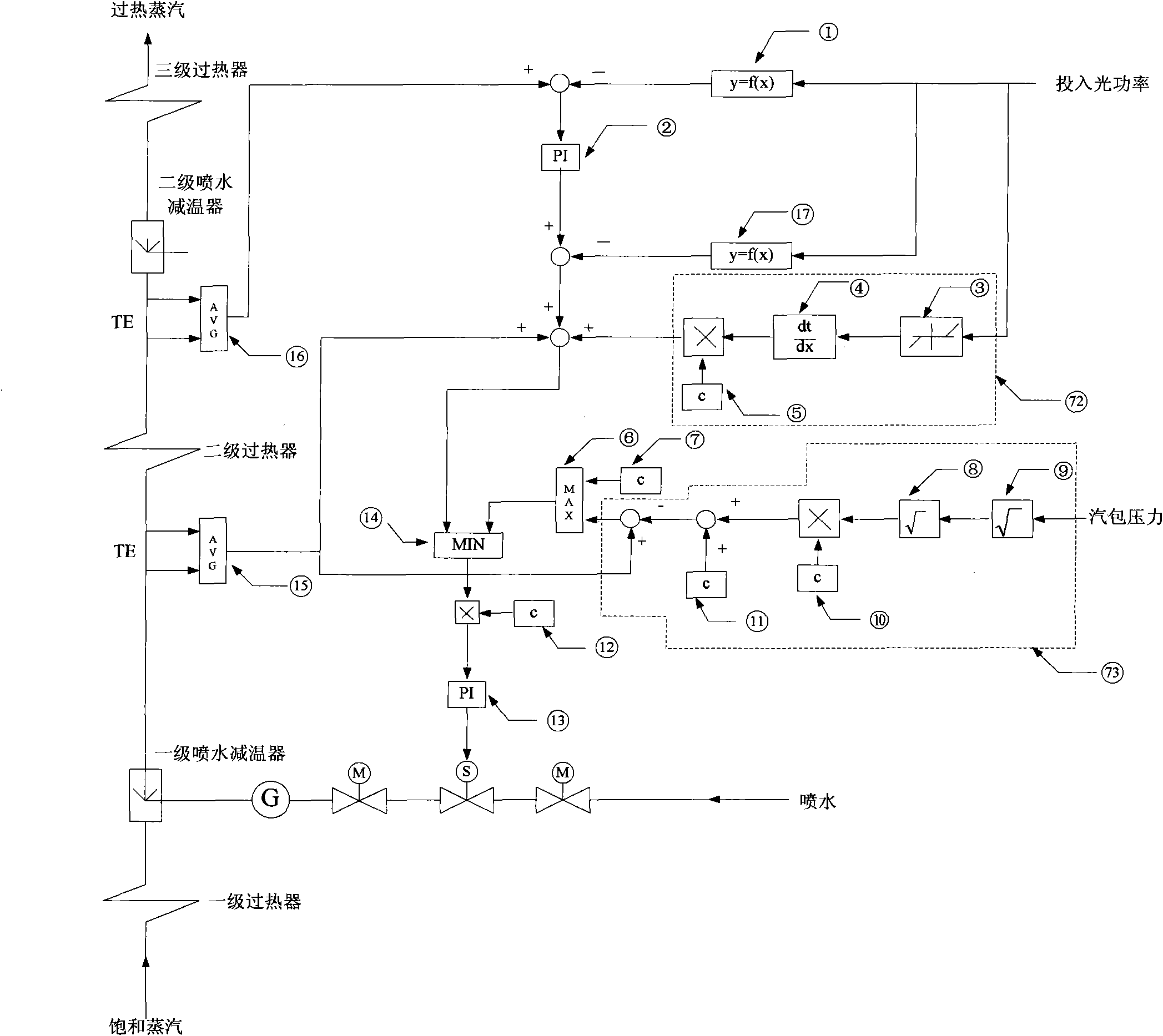

[0031] Such as image 3 As shown, the superheated steam temperature control method of the solar tower thermal power generation receiver includes two-stage steam temperature control. The characteristics of the first-stage steam temperature control include: an outer loop control loop and an inner loop control loop. The outer loop control loop includes the following links: function generator ①, the function describes the relationship between the temperature of the superheated steam after the secondary superheater and the effective radiant light power of the input cavity heat absorber; the average link of collecting data Collect the temperature of the superheated steam after the two secondary superheaters of the cavity heat absorber, and then make an arithmetic mean; PI controller ②, its control algorithm is to perform proportional and integral operations on the deviation of ① and ②. The inner control loop includes: collecting data averaging link It is the arithmetic average o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com