Oxygen carrier for smokeless combustion technology and preparation method thereof

A technology of smokeless combustion and oxygen carrier, which is applied in the direction of fuel, fuel additives, petroleum industry, etc. It can solve the problems of undiscovered oxygen storage capacity and good cycle performance, and achieve strong anti-sintering ability, good cycle performance, and no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

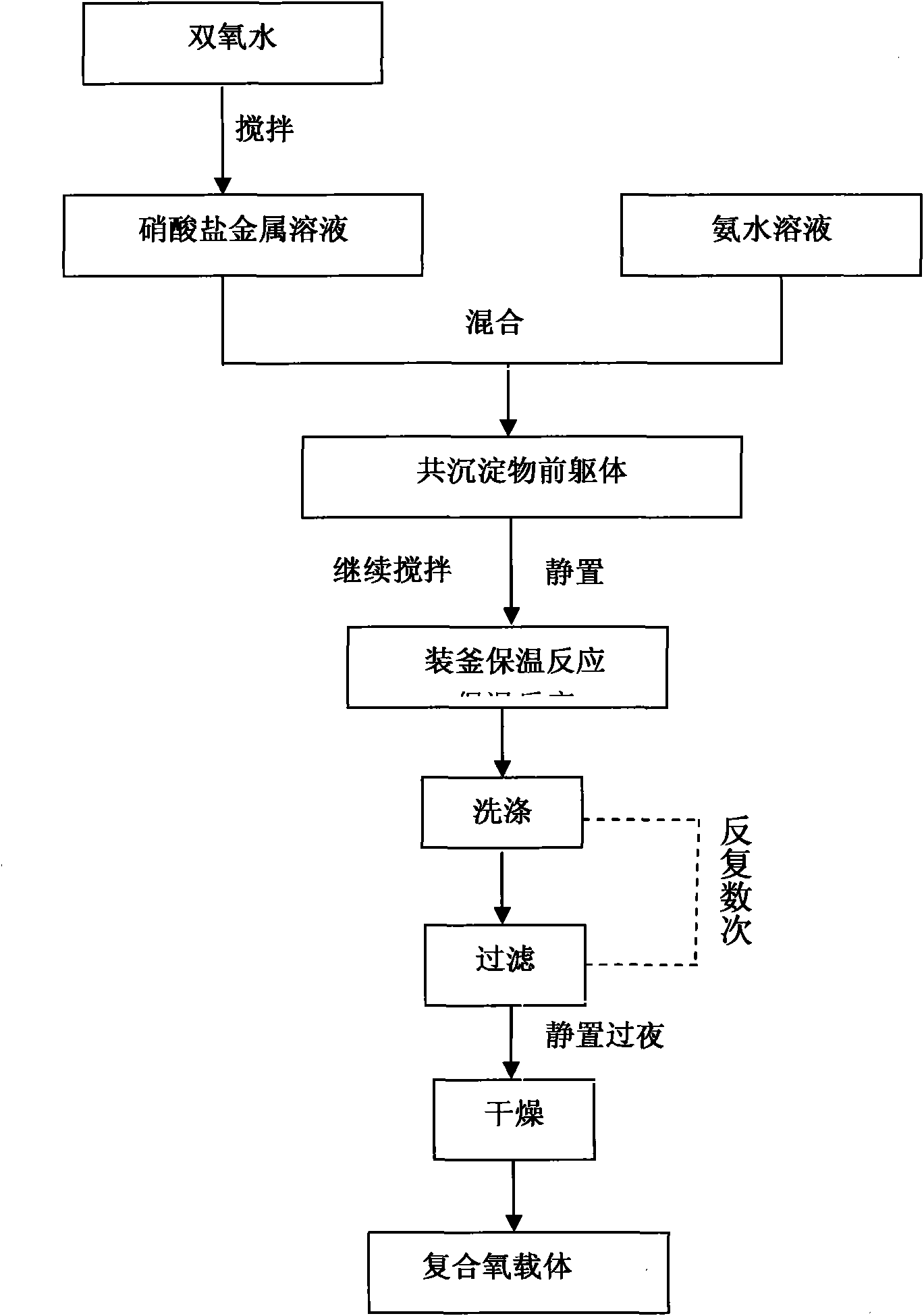

[0021] Prepare Ce and Fe nitrates with a molar ratio of 5:5 into a solution with a total concentration of 0.2mol / L, and then add an appropriate amount of H 2 o 2 , mix evenly. The mixed solution was dropped into 5mol / L ammonia water at a speed of 3ml / min to obtain a precipitate. Continue to stir for 30 min after the precipitation is complete. After aging for 60 minutes, the resulting slurry was moved into a high-pressure reactor (filling degree: 65%), and kept at 200° C. for 48 hours. The obtained product is washed with water, washed with alcohol and dried to obtain a cerium-iron composite oxygen carrier. The oxidation degree X of the prepared oxygen carrier can be recovered from 0.15 to above 0.90, indicating that the lattice oxygen of the oxygen carrier can be restored to more than 90%. It took 42 hours for the oxygen carrier to complete 60 cycle reactions at 800°C, and the methane conversion rate reached 78%. % above, reflects a higher reaction performance.

Embodiment 2

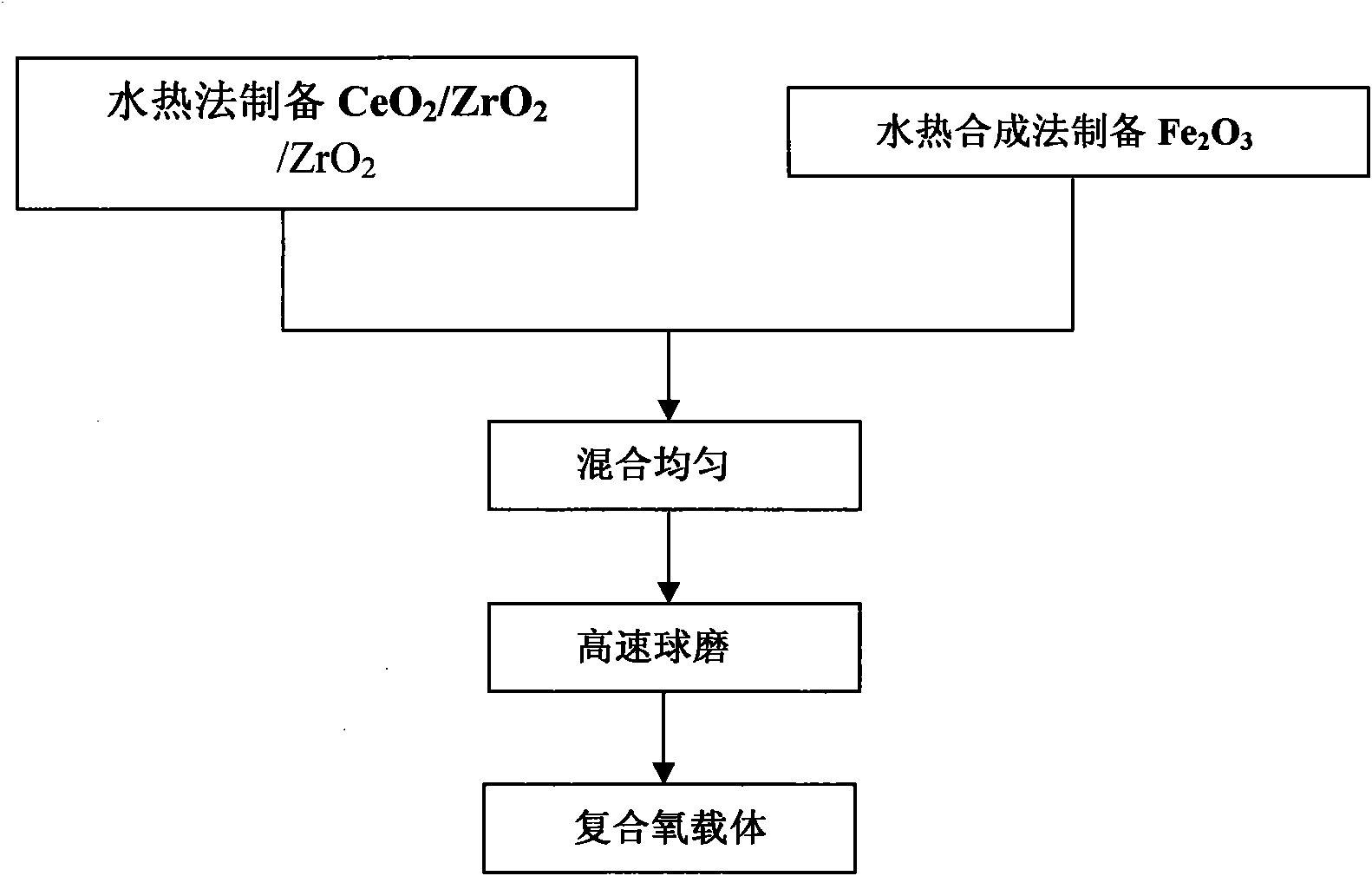

[0023] The nitrates of Ce and Fe were respectively prepared into salt solutions with a concentration of 0.25mol / L, and then an appropriate amount of H 2 o 2 , mix evenly. The mixed solution was dropped into 6M ammonia water at a speed of 5 ml / min to obtain a precipitate. Continue stirring for 60 min after the precipitation is complete. After aging for 60 minutes, the resulting slurry was moved into a high-pressure reactor (filling degree: 65%), and kept at 220° C. for 48 hours. The resulting product was washed with water, washed with alcohol, and dried to obtain pure CeO 2 and Fe 2 o 3 powder. According to the molar ratio of Ce and Fe is 5:5, the CeO 2 and Fe 2 o 3 Mix evenly, and after high-speed ball milling for 30 minutes, a cerium-iron composite oxygen carrier is obtained. The oxidation degree X of the prepared oxygen carrier can be recovered from 0.12 to above 0.92, indicating that the lattice oxygen of the oxygen carrier can be restored to more than 92%. It too...

Embodiment 3

[0025] Prepare Ce, Fe, Zr nitrate with a molar ratio of 0.5:0.35:0.15 into a solution with a total concentration of 0.25mol / L, and then add an appropriate amount of H 2 o 2 , mix evenly. The mixed solution was dropped into 5M ammonia water at a speed of 5 ml / min to obtain a precipitate. Continue stirring for 60 min after the precipitation is complete. After aging for 90 minutes, the resulting slurry was moved into a high-pressure reactor (filling degree: 60%), and kept at 220° C. for 48 hours. The obtained product is washed with water, washed with alcohol and dried to obtain a cerium-iron-zirconium composite oxygen carrier. The oxidation degree X of the prepared oxygen carrier can be recovered from 0.10 to above 0.95, indicating that the lattice oxygen of the oxygen carrier can be restored to more than 95%. It took 35 hours for the oxygen carrier to complete 55 cycle reactions at 850°C, and the methane conversion rate reached 90. % above, reflects a higher reaction perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com