Alarm control system and method for fuel oil system of excavator

A fuel system and control system technology, which is applied in the direction of charging system, earthmoving machine/shovel, mechanical equipment, etc. Easy to observe, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

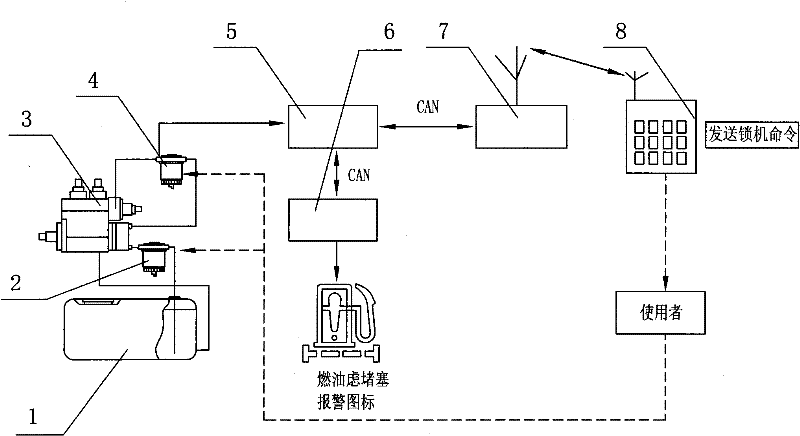

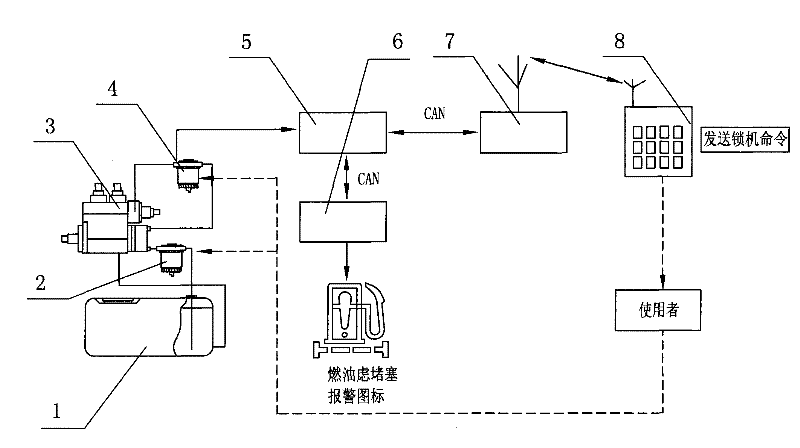

[0021] Embodiment one: see figure 1 As shown, an alarm control system for excavator fuel system, the fuel system includes a fuel tank 1, pre-filter 2, high-pressure oil pump 3 and fine filter 4, the outlet of the fine filter 4 is provided with a pressure sensor, The signal output end of described pressure sensor is connected with the input end of main controller 5, and the output end of described main controller 5 is connected with display device 6 and GPS transmission module 7 respectively via CAN bus, and described GPS transmission module is connected with remote monitoring The lock machine control center 8 is connected.

[0022] When the excavator is in use and the fuel system is blocked, the pressure at the outlet of the fine filter will change. This pressure change will be detected by the pressure sensor installed here and transmitted to the main controller. The controller processes the received information and divides the congestion situation into three levels, and tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com