Method for preparing monoclinic lead tungstate nano belt crystal material

A monoclinic lead tungstate and crystal material technology, applied in polycrystalline material growth, crystal growth, single crystal growth, etc., to achieve low synthesis cost, easy surface modification, and environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

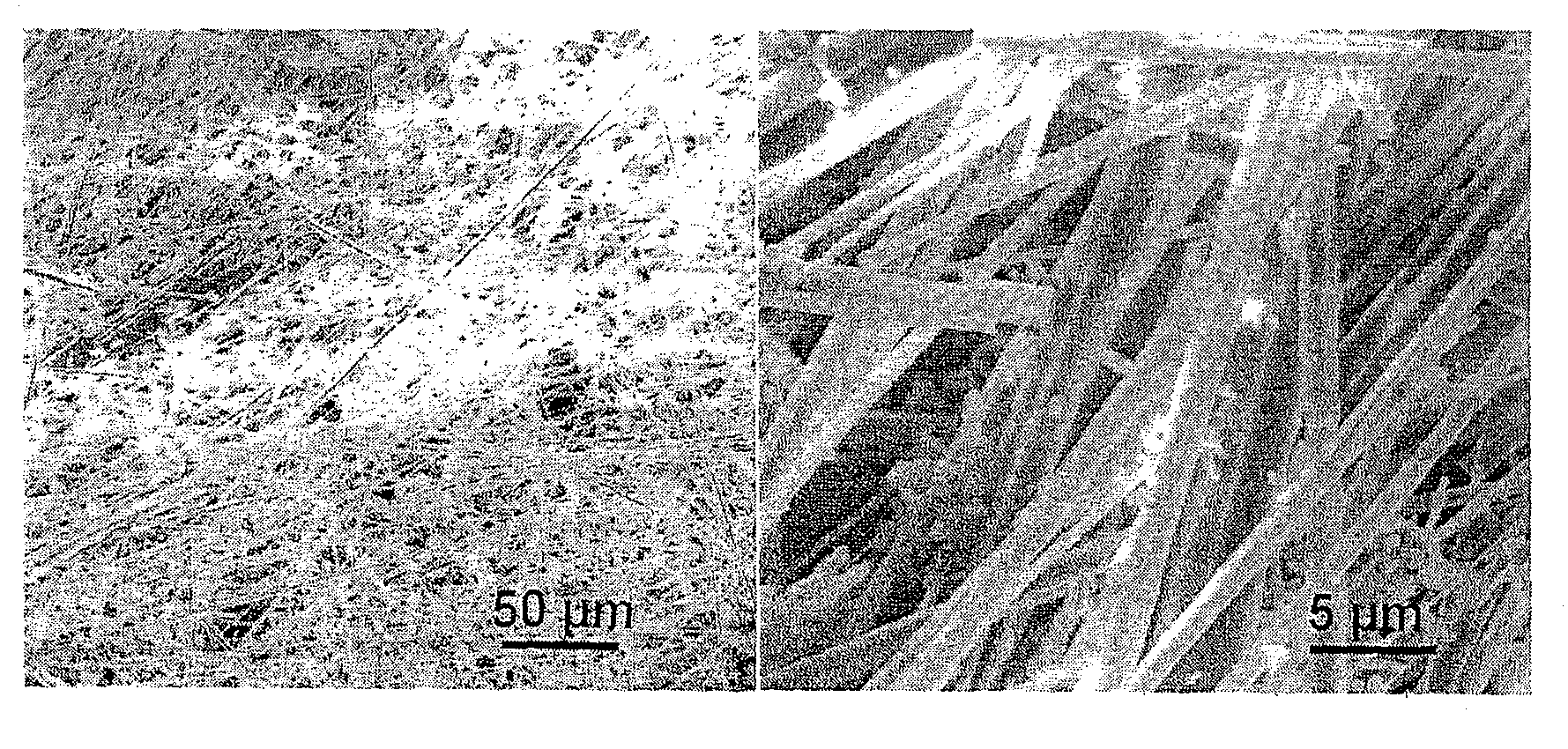

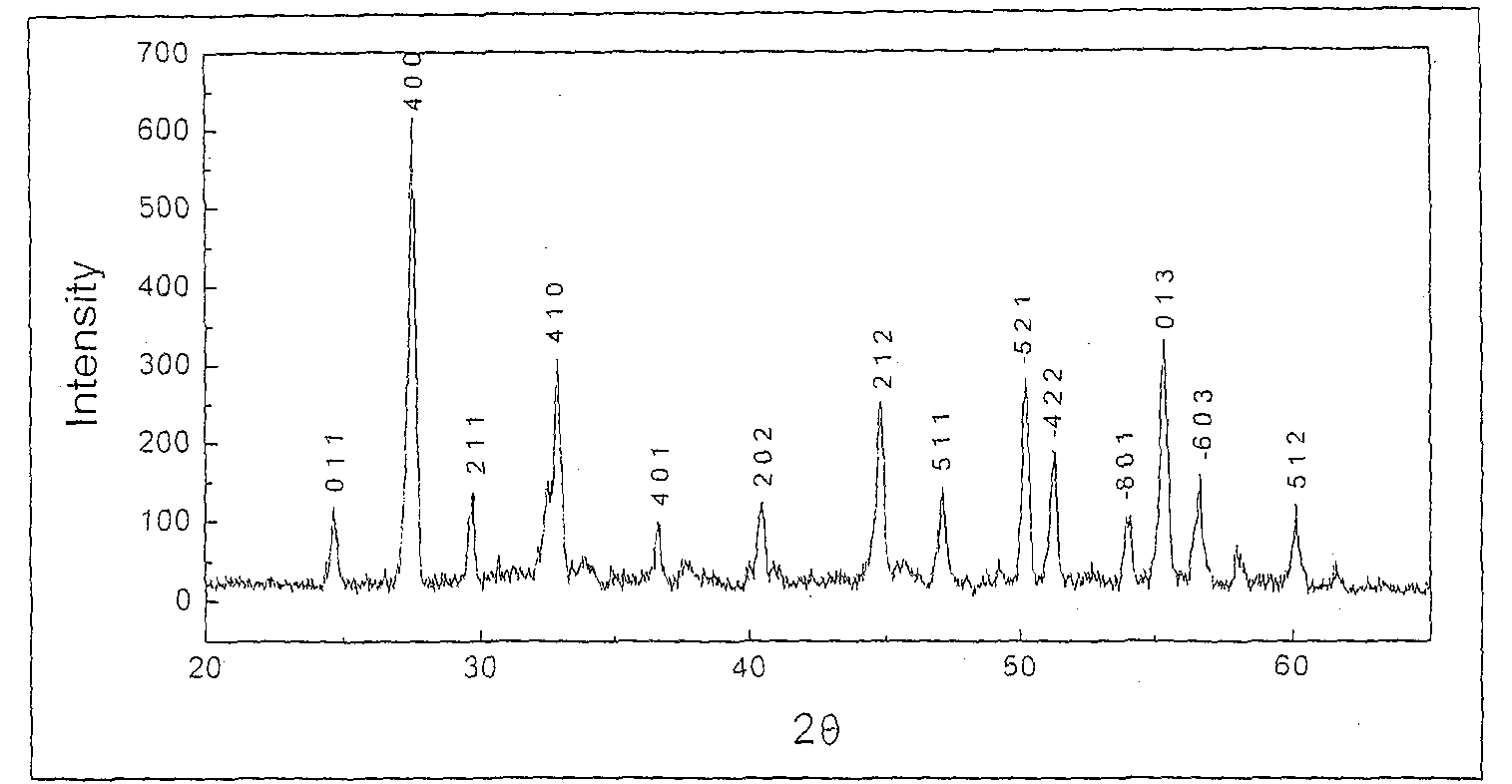

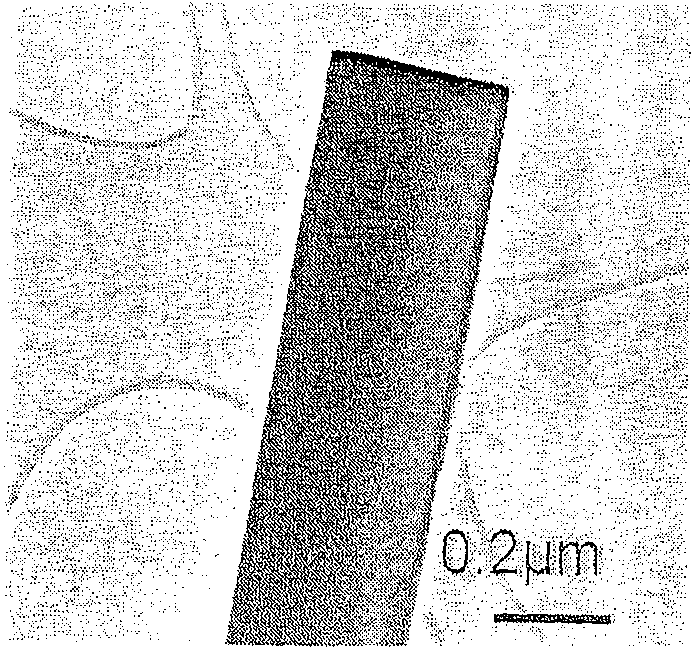

Image

Examples

Embodiment 1

[0030] Specific synthesis method of monoclinic lead tungstate nanobelt crystal material

[0031] The raw material for the synthesis of lead tungstate nanobelt crystal material is LiNO 3 、KNO 3 , lead nitrate (Pb(NO 3 ) 2 ), sodium tungstate (Na 2 WO 4 ), ammonia (NH 3 ·H 2 O), the reaction that takes place is as follows:

[0032] (a)Pb(NO 3 ) 2 +2NH 3 ·H 2 O→Pb(OH) 2 ↓+2NH 4 NO 3 ,

[0033]

[0034] The specific operation steps are as follows:

[0035] Step 1. LiNO3 = 10% and KNO3 = 90% are weighed and mixed as reaction solvents.

[0036] Step 2. Weighing as the reactants according to the weight percent of lead nitrate (Pb(NO3)2) = 10%, and the weight percent of sodium tungstate (Na2WO4·2H2O) = 90%.

[0037] Step 3, preparing an alkaline solution by dissolving ammonia in an appropriate amount of water.

[0038] Step 4, heating the reaction, taking the reaction raw materials and reaction solvent added to the reaction vessel as the total weight, the reaction...

Embodiment 2

[0042] Specific synthesis method of monoclinic lead tungstate nanobelt crystal material

[0043] The raw material for the synthesis of lead tungstate nanobelt crystal material is LiNO 3 、KNO 3 , lead chloride (PbCl 2 ), sodium tungstate (Na 2 WO 4 ), ammonia (NH 3 ·H 2 O), the reaction that takes place is as follows:

[0044] (c) PbCl 2 +NH 3 ·H 2 O→Pb(OH) 2 ↓+NH 4 Cl,

[0045]

[0046] The specific operation steps are as follows:

[0047] Step 1, by weight percentage LiNO 3 = 42% and KNO 3 =58% weighed and mixed as a reaction solvent.

[0048] Step 2, press lead nitrate (PbCl 2) weight percentage=51%, sodium tungstate (Na 2 WO 4 2H 2 O) % by weight = 49% Weighed as reactant.

[0049] Step 3, preparing an alkaline solution by dissolving ammonia in an appropriate amount of water.

[0050] Step 4, heating the reaction, taking the reaction raw materials and reaction solvent added to the reaction vessel as the total weight, preparing the reaction raw materi...

Embodiment 3

[0054] Specific synthesis method of monoclinic lead tungstate nanobelt crystal material

[0055] The raw material for the synthesis of lead tungstate nanobelt crystal material is LiNO 3 、KNO 3 , lead acetate ((CH 3 COO) 2 Pb), sodium tungstate (Na 2 WO 4 ), the reaction that occurs is as follows:

[0056]

[0057]

[0058] The specific operation steps are as follows:

[0059] Step 1, by weight percentage LiNO 3 = 42% and KNO 3 =58% weighed and mixed as a reaction solvent.

[0060] Step 2, press lead nitrate (PbCl 2 ) weight percentage=51%, sodium tungstate (Na 2 WO 4 2H 2 O) % by weight = 49% Weighed as reactant.

[0061] Step 3, heating reaction, take the reaction raw materials and reaction solvent added to the reaction vessel as the total weight, prepare the reaction raw materials with a weight percentage of 0.5% to 50% and the reaction solvent with a weight percentage of 50% to 99.5%, and put them into the reaction together Add an appropriate amount of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com