Positive temperature coefficient macromolecular composition, positive temperature coefficient protection component and manufacturing methods

A positive temperature coefficient, polymer technology, applied in the field of positive temperature coefficient polymer composition, can solve the problems of limited delivery time, processing rate, large-scale cracking, affecting the time and cost of the preparation process, etc., to improve the burden Temperature coefficient effect, effect of saving preparation process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

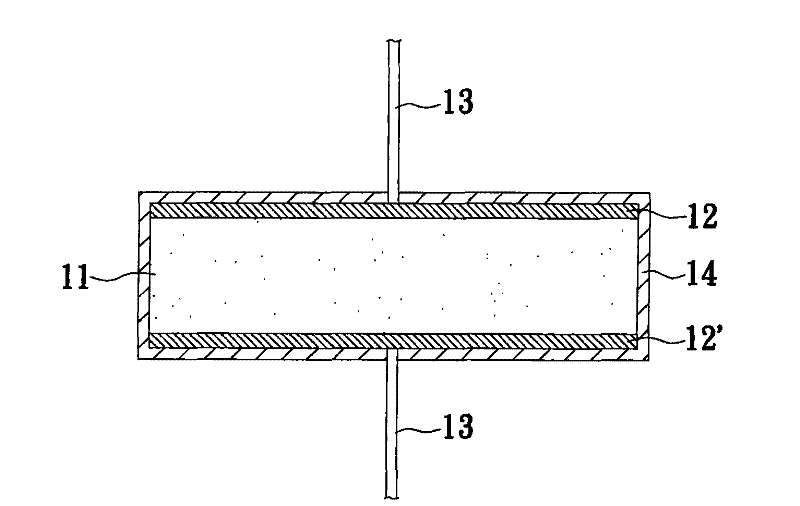

preparation example Construction

[0026] Preparation of silane-grafted polyamide:

[0027] Add a silane crosslinking agent containing unsaturated carbon bonds and alkoxy groups, and an organic peroxide to the polyamide, optionally add a catalyst, and put it into a plastic spectrometer (Brabender Plasti-Corder TorqueReometer / PLE-330) to mix evenly , react at a temperature range of 160 to 280 ° C and a screw speed range of 5 to 200 rpm / min for 6 to 25 minutes, wherein the organic peroxide first forms free radicals due to thermal fracture, and the free radicals are transferred to the polyamide, and then combined with The unsaturated carbon bond on the silane crosslinking agent undergoes grafting reaction, so that silane grafted polyamide can be obtained.

[0028] The types of polyamides mentioned above are not limited, and the polyamides to be used can be selected according to the operating temperature required by the positive temperature coefficient protection components, such as nylon 6, 9, 12, 6-6, 5-10, 6-12,...

Embodiment 1

[0050] In 99.2 parts by weight of nylon 12 (model: Grilamid L20G, produced by EMS), add 0.8 parts by weight of vinyltrimethoxysilane (Vinyltrimethyloxysilane, VTMS, Dow Corning Co.), 0.6 parts by weight of diisopropyl peroxide Benzene (dicumyl peroxide, DCP, Aldrich Chemical Co.) and 0.5 parts by weight of dibutyltin dilaurate (DBTDL) were put into a plastic spectrometer and mixed evenly, at a temperature of 250 °C and a screw speed of 40 rpm / min, the Following the reaction shown in Scheme 1, vinyltrimethoxysilane-grafted nylon 12 can be obtained after 15 minutes of reaction.

[0051] Process 1

[0052]

[0053] The silane-grafted nylon 12 obtained above was pulverized and pulverized using a pulverizer (Retsch) and a mill (Retsch / ZM-2000) to form a powder. Linked for 3 hours to obtain cross-linked silane-grafted nylon 12.

[0054] Process 2

[0055] 1. Hydrolysis reaction

[0056]

[0057] 2. Condensation reaction

[0058]

[0059] Mix 35 parts by weight of nano-...

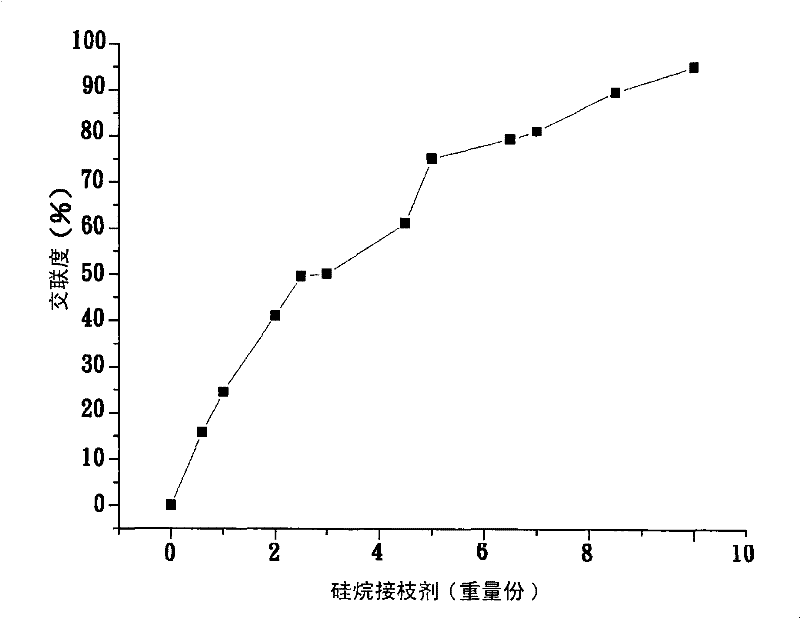

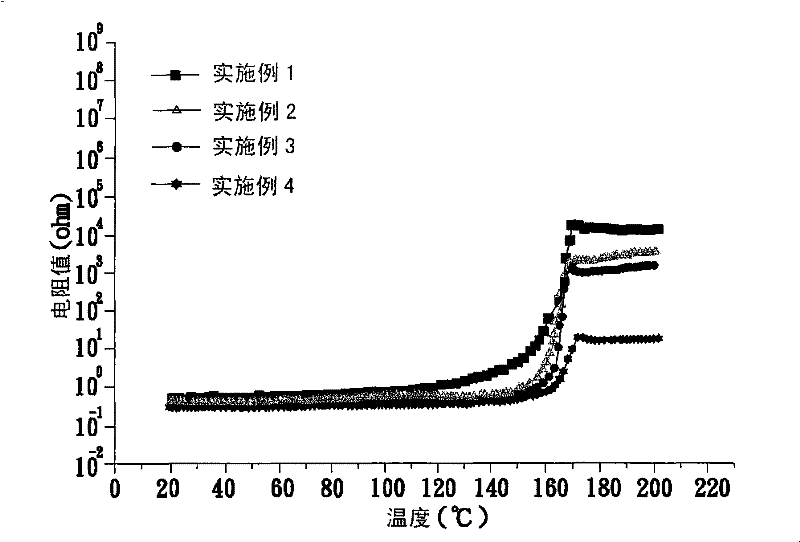

Embodiment 2 and 4

[0061] The preparation method of the positive temperature coefficient polymer compositions of Examples 2 and 4 is substantially the same as that of Example 1, the main difference lies in the content of vinyltrimethoxysilane and nylon 12 as shown in Table 1 below.

[0062] Table 1

[0063] Nylon 12 (parts by weight)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com