Electric heating roasting preheating electrolytic bath and cleaning and roasting method

An electrolytic cell and electric heating technology, which is applied in the field of electrolytic cells, can solve the problems of cathode carbon block layer peeling, poor operating environment, and high labor intensity, and achieve the effects of reducing roasting costs, simplifying operations, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

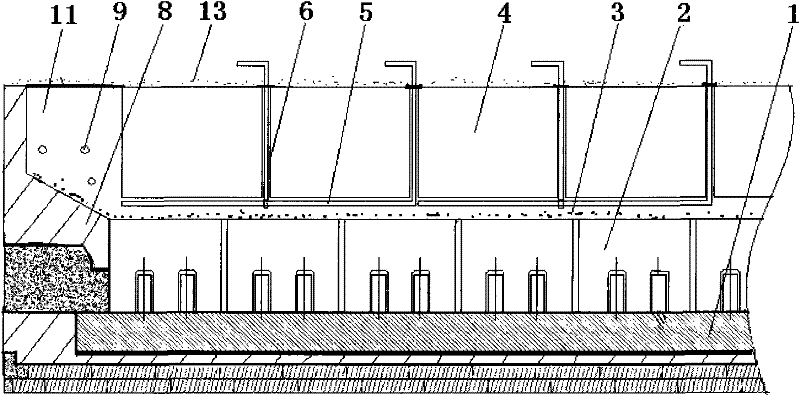

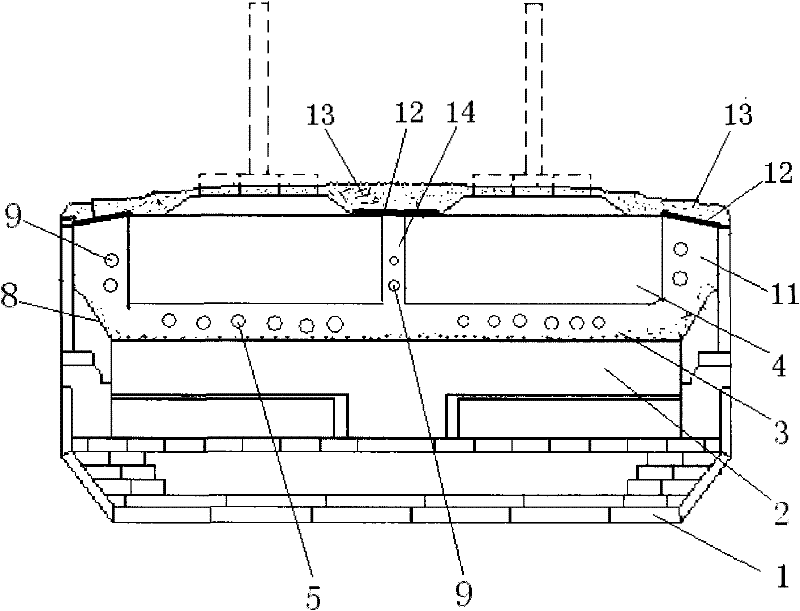

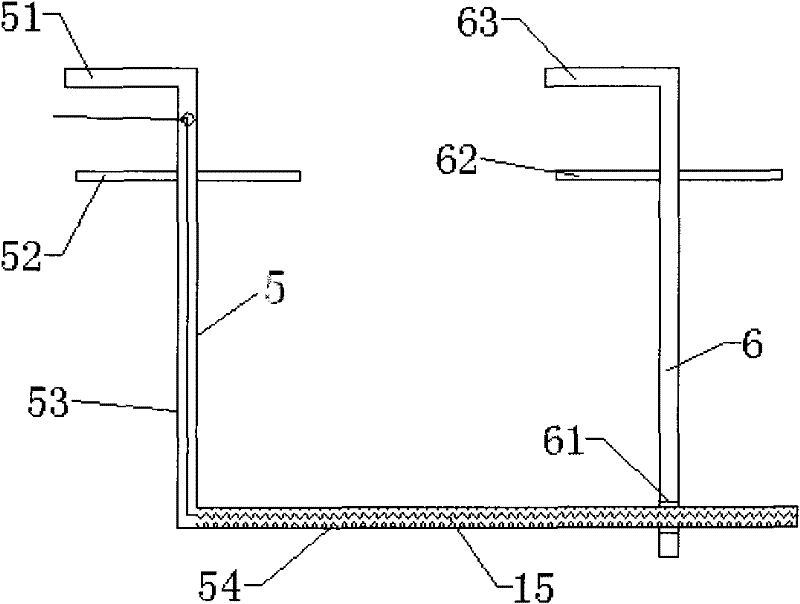

[0038] The electric heating roasting and preheating electrolytic cell provided by the present invention includes a cell body 1 and a cathode carbon block 2 fixed at the bottom of the cell body 1 and an artificial extension leg 8 around the cathode carbon block 2, as well as a cell body 1 capable of raising and lowering Anode 4, below the anode 4, the gap cavity 14 between the anode 4, the side cavity 11 between the anode 4 and the tank 1 is movably provided with an electric heating element, the electric heating element is a hollow straight stainless steel tube 9 and The hollow L-shaped stainless steel tube 5, the resistance wire 15 is placed in the stainless steel tube, and the lead out of the tube is electrically connected with the conventional electric control device of the prior art. The specific setting of the electrically heated stainless steel tube is: the vertical of the L-shaped stainless steel tube 5 The straight end 53 is provided with a handle 51, the lower part of th...

Embodiment 2

[0041] The method for clean roasting and preheating of the electric heating roasting and preheating electrolytic cell provided by the present invention goes through the following steps:

[0042] A. Install the anode 4 above the cathode carbon block 2 in the tank 1, and ensure that the anode 4 is in good contact with the horizontal bus, and the small box clamp is in a tight state;

[0043] B. Lift the anode 4, and spread cryolite 3 with a thickness of 20mm on the surface of the cathode carbon block 2 and the artificial leg 8;

[0044] C. Install multiple L-shaped electrically heated stainless steel tubes 5 between the cathode carbon block 2 and the anode 4 according to Example 1. After installation, appropriately reduce the height of the anode 4, and ensure that the L-shaped electrically heated stainless steel tube 5 and the cathode carbon block Keep a distance of 30mm between 2 and the anode 4; then install multiple straight electrically heated stainless steel tubes 9 in the slot cav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com