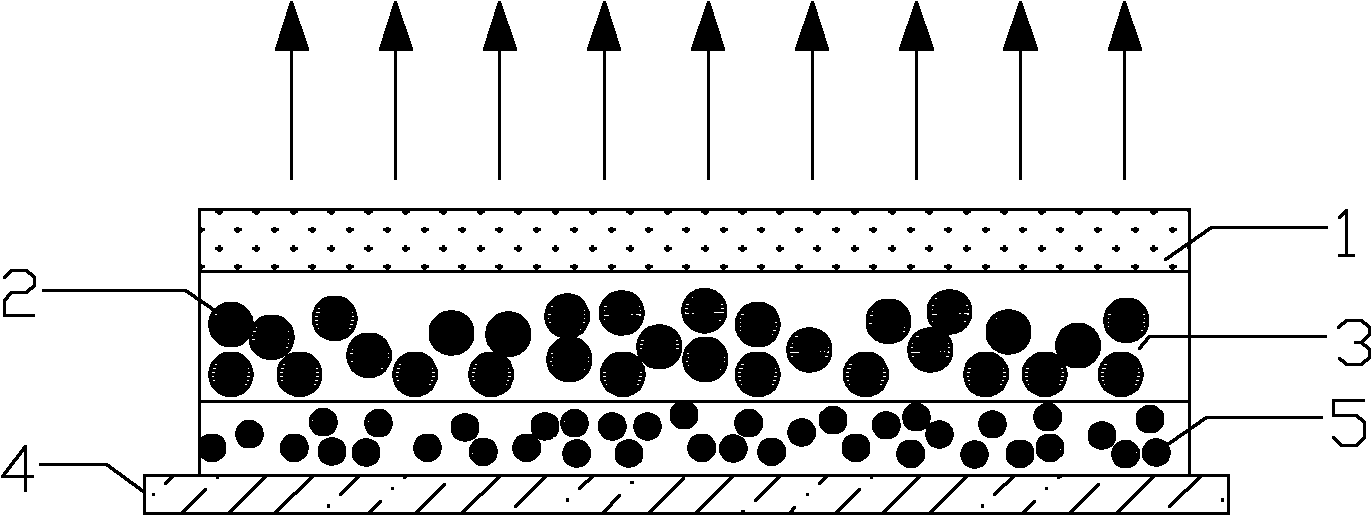

Long-persistence fluorescent source and preparation method thereof

A technology with long afterglow and production method, which is applied in the directions of light source, fluorescence, lighting and heating equipment, etc., can solve the problems of increasing production cost and many production steps, and achieves the effect of saving cost, improving light efficiency and simplifying process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

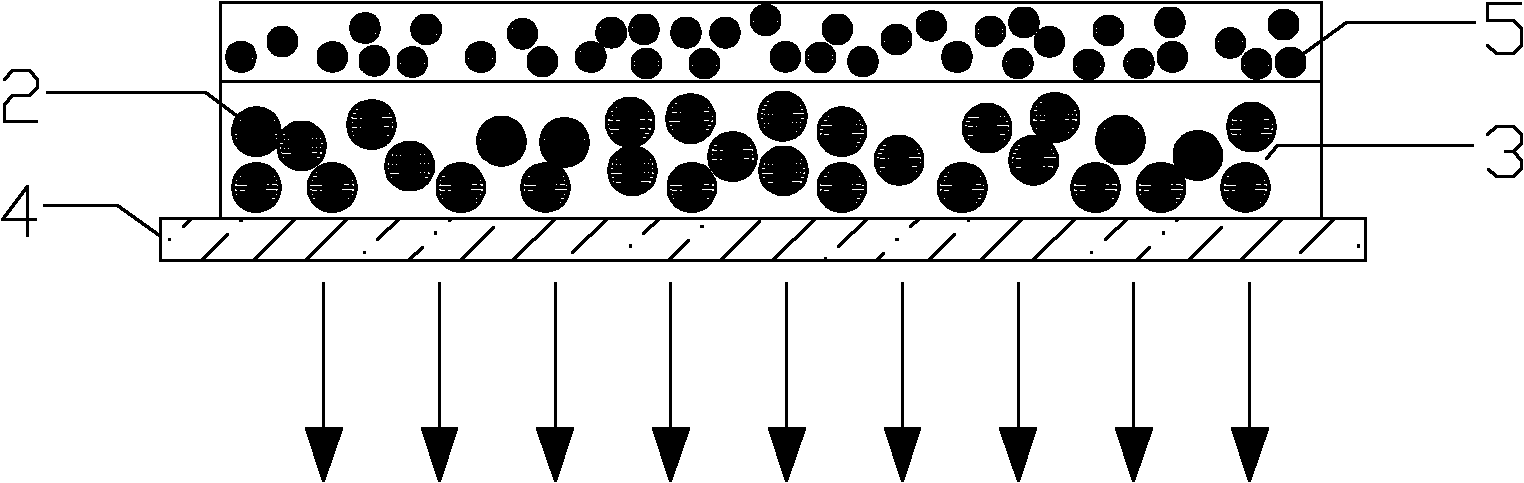

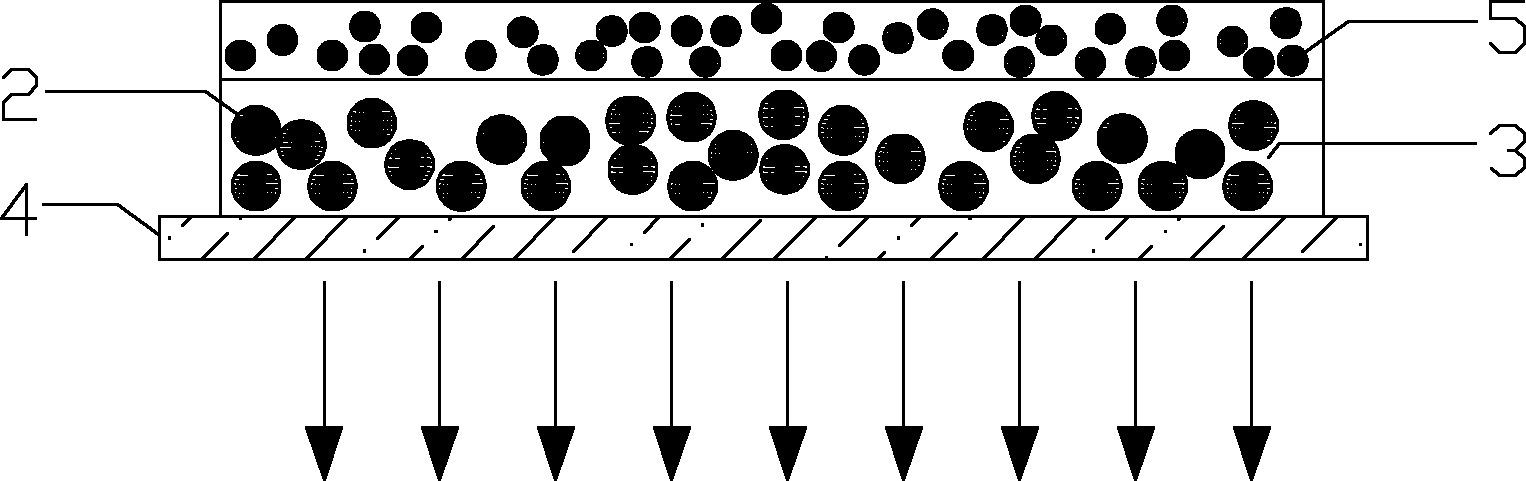

Method used

Image

Examples

Embodiment 11

[0019] Embodiment 11) material selection: (according to the percentage by weight is 100g meter) fluorescent powder filler or glass bead filler 75g; Vinyl resin 5g; Terpineol 20g; Above-mentioned base material selects transparent PET film for use; The selected fluorescent powder filler is luminescent Material ZnS: Cu; selected glass beads filler: BaO, SiO 2 A mixture mixed in any proportion; the average particle size range is 20 μm, and its refractive index is 1.8.

[0020] 2) Weigh the vinyl acetate resin and terpineol in the above materials in proportion, place them in a container, and heat them in a water bath to 80°C to completely dissolve the vinyl acetate resin in the terpineol to prepare an intermediate carrier, cool down for later use ; 3) After mixing the carrier obtained in step 2) with the phosphor filler weighed in the above ratio, after stirring with a high-speed mixer for 30 minutes, the carrier and the phosphor filler form a uniform system, and the required phosp...

Embodiment 21

[0021] Embodiment 21) Material selection: (according to 100g by weight percentage) 40g of fluorescent powder filler or glass bead filler; 20g of polyurethane resin; 40g of ethyl acetate; the above-mentioned base material is selected from glass; the above-mentioned fluorescent powder filler is an aluminate system to emit light MaterialSrAl 2 o 4 :Eu 2+ , glass beads filled with SiO 2 、TiO 2 , B 2 o 3 , ZnO mixed in any proportion, the average particle size is 50μm, and the refractive index is 2.

[0022] 2) Weigh the polyurethane resin and ethyl acetate in the above materials in proportion, place them in a container, and heat them in a water bath to 80° C., so that the polyurethane resin is completely dissolved in ethyl acetate, and prepare the carrier of the intermediate, and cool down for later use; 3 ) After mixing the carrier obtained in step 2) with the phosphor filler weighed in the above proportion, after stirring with a high-speed mixer for 30 minutes, the carrier...

Embodiment 31

[0023] Embodiment 31) material selection: (according to the weight percentage is 100g meter) fluorescent powder filler or glass bead filler 80g; Epoxy resin 10g; Ethylene glycol monomethyl ether 5g; Terpineol 5g; The phosphor filler is selected as the silicate system luminescent material Zn 2 SiO 4 : Mn, the selected glass bead filler is B 2 o 3 , ZnO, Na 2 O and K 2 O is a mixture mixed in any proportion, with an average particle size of 80 μm and a refractive index of 2.5.

[0024]2) Weigh the epoxy resin, ethylene glycol monomethyl ether and terpineol in the above materials in proportion, put them in a container and heat them in a water bath to 80°C, and stir at this temperature for 3 hours to completely dissolve the terpineol Prepare the carrier of the intermediate in ethylene glycol monomethyl ether, cool down for later use; 3) mix the carrier obtained in step 2) with the fluorescent powder filler weighed in the above ratio, and stir for 30 minutes with a high-speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size diameter | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com