Intrinsic safety photoacoustic spectrum gas monitoring system based on optical acoustic sensor

A technology of acoustic wave sensor and photoacoustic spectroscopy, applied in color/spectral characteristic measurement, scientific instruments, material analysis through optical means, etc., can solve problems affecting performance, damage, loss of function, etc., and achieve fast response speed and monitoring sensitivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below in conjunction with accompanying drawing and embodiment, and present implementation example has provided detailed embodiment and concrete operation step and is implemented under the premise of technical solution of the present invention, but the scope of protection of the present invention is not limited to Examples described below.

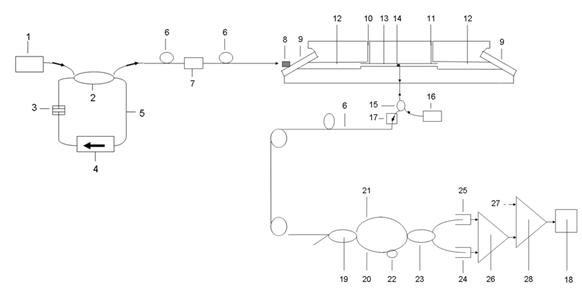

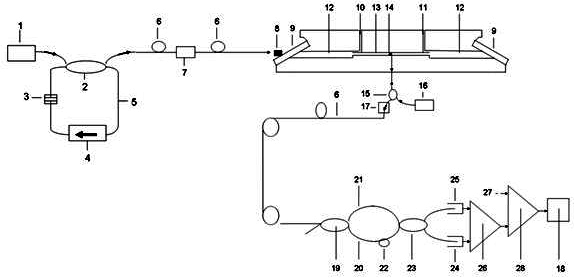

[0021] Such as figure 1 As shown, the implementation example includes a light source device, the laser generated by the device is connected to the photoacoustic cell device through the optical fiber 6 through the fiber collimator 8, and the incident direction of the laser is collimated with the axis of the photoacoustic cell device; the optical acoustic wave sensor and The photoacoustic cell device is connected, and the photoacoustic cell device communicates with the gas to be measured; wherein the phase-shifted erbium-doped grating optical fiber 14 of the 1 / 4 wavelength in the optical aco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com