Composite battery, preparation method and application thereof

A composite battery and battery technology, applied in secondary batteries, nickel batteries, lead-acid batteries, etc., can solve the problems of battery life less than one year, battery life shortening, high price battery consistency, etc., to achieve weight reduction, The effect of prolonging the service life and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

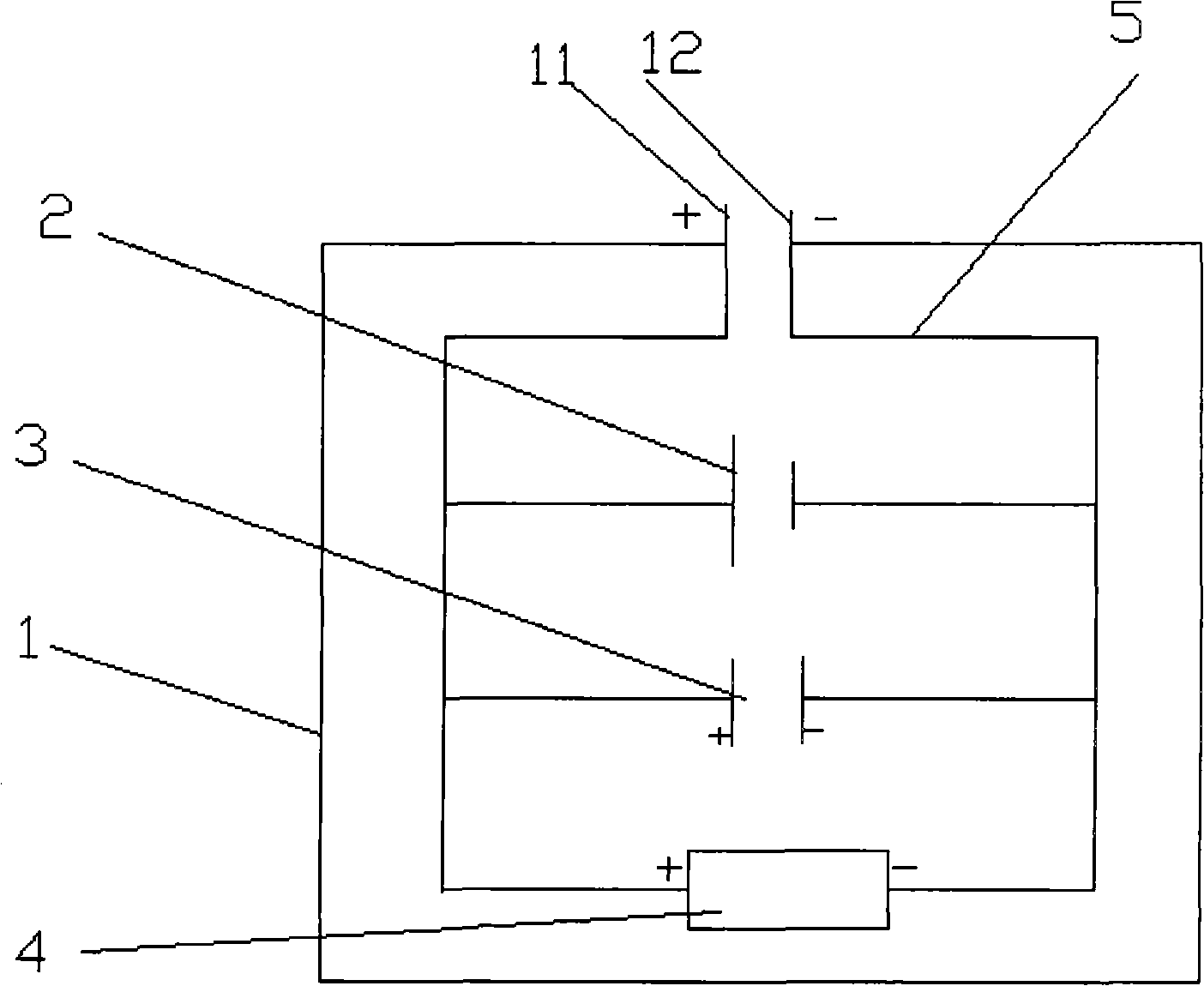

[0066] The embodiment of the present invention also provides the above composite battery preparation method, including the following steps:

[0067] Provide battery case 1, matrix battery 2, supercapacitor 3 and voltage equalizing circuit board 4 respectively;

[0068] Connecting the parent battery 2, the supercapacitor 3 and the equalizing circuit board 4 in parallel to form a parallel system;

[0069] The positive and negative poles of the parallel system are respectively electrically connected to the positive and negative terminals 11 and 12 on the housing 1;

[0070] The mother battery 2, the supercapacitor 3 and the voltage equalizing circuit board 4 after the electrical connection are completed are placed in the battery casing 1 and fixed to obtain the composite battery.

[0071] The steps in the above composite battery preparation method can be appropriately and flexibly adjusted according to actual conditions, such as Figure 8 As shown, the steps are as follows:

...

example 1

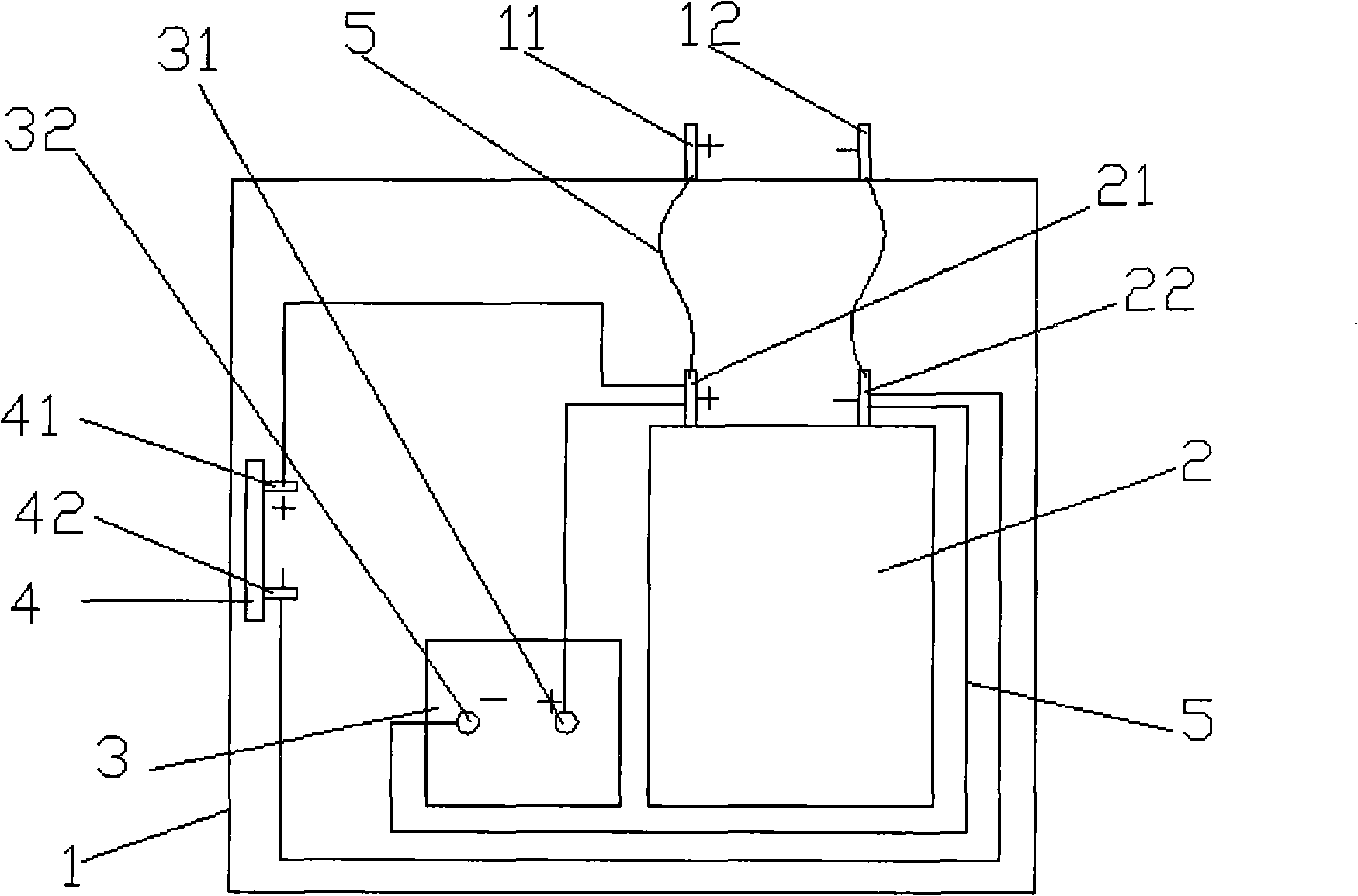

[0104] Such as Figure 4 As shown, the parent battery 2 of the 12V, 100Ah lead-acid battery in the compound battery of this embodiment and the supercapacitor module 3 of 15V~110F are fixed in the inner cavity of the battery case 1, and the voltage equalizing circuit board 4 is welded and screwed 6 Fixed between the positive and negative poles 31 and 32 of the supercapacitor 3, the positive and negative terminals 41 and 42 on the voltage equalizing circuit board 4 are respectively electrically connected to the positive and negative poles 31 and 32 of the supercapacitor 3. , negative poles 31, 32 are respectively electrically connected to the positive and negative poles 21, 22 of the mother battery 2, the positive and negative poles 21, 22 of the mother battery 2 extend outside the battery case 1, and are connected to the positive and negative terminals 11 on the battery case 1 , 12 are integrated, and the electrical connection of each element in this embodiment is connected by ...

example 2

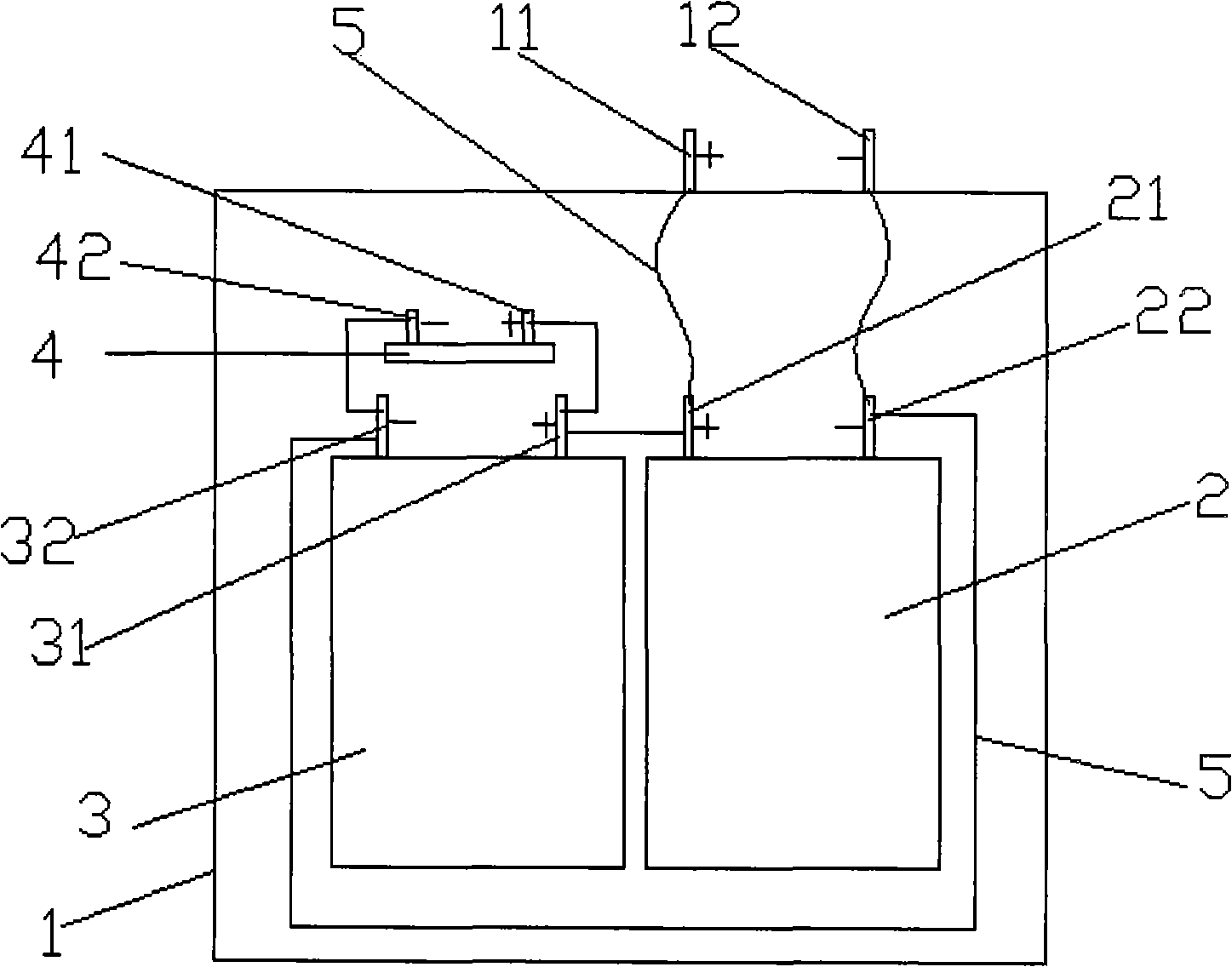

[0121] Such as image 3 As shown, the 24V, 10Ah lithium iron phosphate parent battery pack 2 in the composite battery of this embodiment is vertically fixed in the inner cavity of the battery case 1, and the 27V, 35F supercapacitor module 3 is horizontally fixed in the inner cavity of the battery case 1 At the bottom, the voltage equalizing circuit board 4 is fixed on the side wall of the inner cavity of the battery case 1 close to the super capacitor 3, the positive and negative terminals 41, 42 on the voltage equalizing circuit board 4 and the positive and negative electrodes 31, 32 of the super capacitor 3 The positive and negative poles 21 and 22 of the mother battery 2 are respectively electrically connected to the positive and negative poles 21 and 22 of the mother battery 2, and the positive and negative poles 21 and 22 of the mother battery 2 are respectively electrically connected to the positive and negative terminals 11 and 12 on the battery case 1. The electrical c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy density | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com