Bulk phase catalyst and preparation method thereof

A technology of bulk catalyst and precipitant, which is used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve problems such as inability to obtain large-pore bulk catalysts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

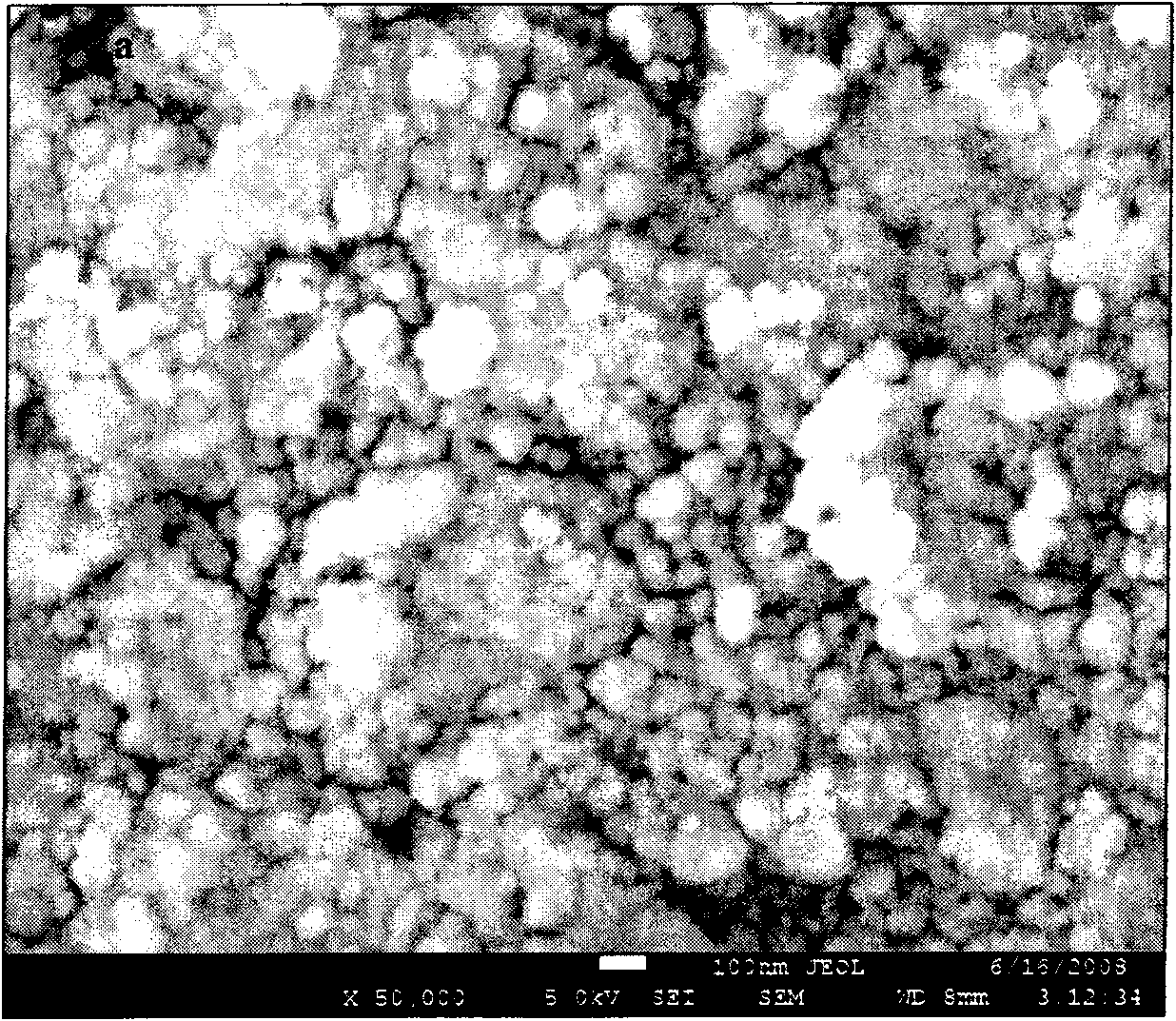

[0076] 165g minus four-line oil, 25g light deasphalted oil, 33g SP-60 and 12g lecithin were heated and dissolved at 100°C, and mixed uniformly; 750g aluminum nitrate nonahydrate, 80g silica sol (wherein containing silicon dioxide is 30wt%) , Heat to 100°C to melt, add dropwise to the above mixture, mix for 30 minutes to form a uniform supersolubilizing gel group, add 110g of ammonia gas to the above system at 100°C under airtight conditions, carry out precipitation reaction, and then age for 20 hours , to obtain nano-silica-alumina gel. The nano-silica-alumina gel was washed three times with distilled water, and dried at 120° C. for 10 hours to obtain a dry powder of the nano-silicon-alumina gel. Calcining part of the dried nano-silica-alumina gel powder at 250° C. for 2 hours to obtain the calcined nano-silicon-alumina gel powder.

[0077] Mix 62g of second-line oil and 8g of SP-80, heat to dissolve at 80°C, and mix evenly; heat 320g of nickel nitrate to 80°C to melt, add dr...

Embodiment 2

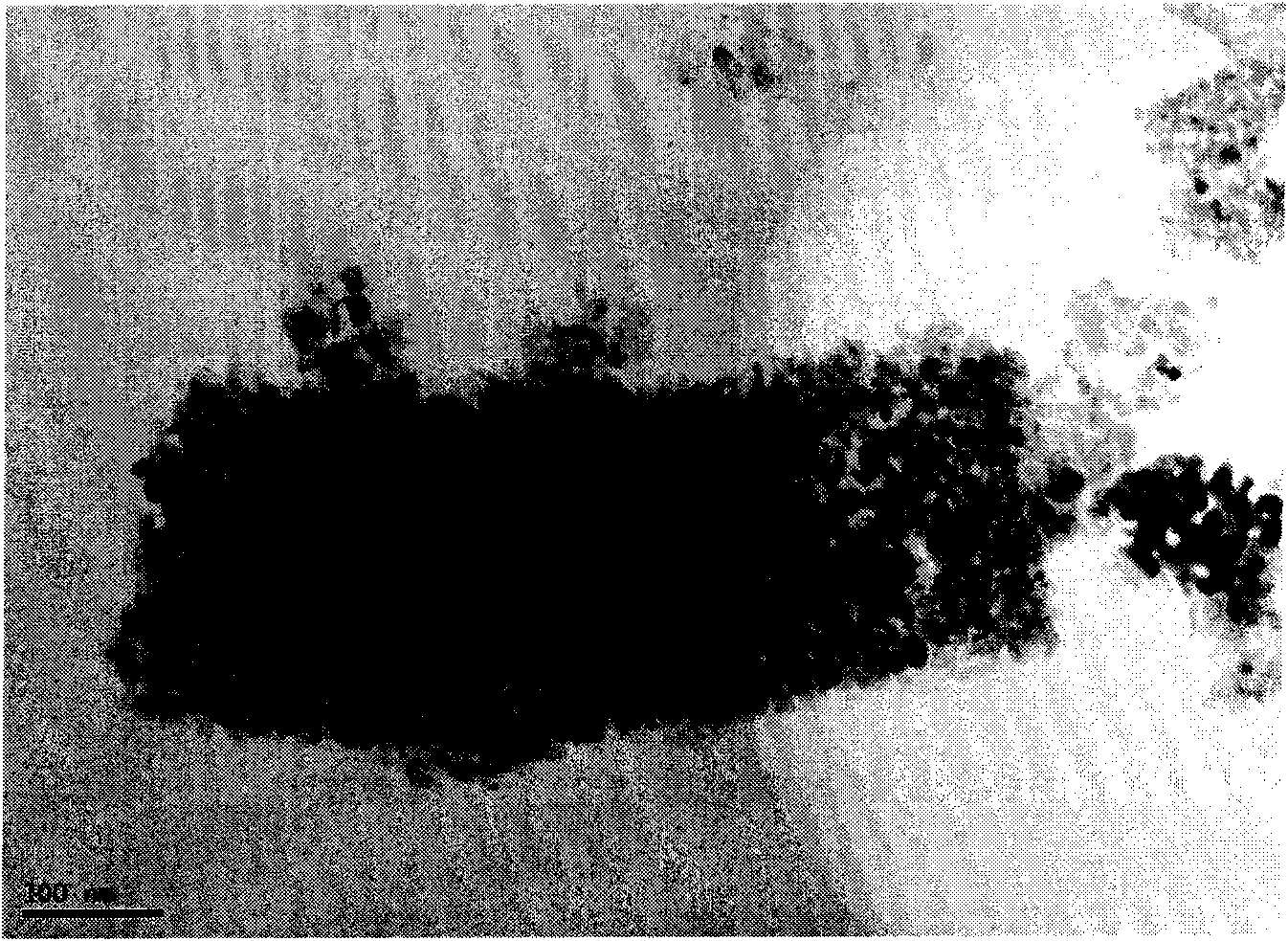

[0081] Under stirring conditions, 375g of aluminum nitrate nonahydrate and 90g of urea were mixed and heated to 100°C, and added to a mixture of 32g of polyisobutylene maleate triethanolamine maleate and 88g of 150HVI neutral oil at the same temperature to form supersolubilizing micelles , and then reacted at 100°C for 3 hours to obtain nano-aluminum hydroxide gel. Wash three times with 200ml of distilled water, and dry at 120°C for 10 hours to obtain dried nanometer aluminum hydroxide gel powder.

[0082] Mix 62g of second-line oil and 8g of SP-80, heat to dissolve at 80°C, and mix evenly; heat 20g of nickel nitrate to melt at 80°C, add dropwise to the above mixture, and mix for 15 minutes to form a uniform supersolubilizing colloid, 136g of molybdenum pentachloride and 150g of ethanol solution were added to the micelles, and finally 198g of ammonia water with a weight concentration of 33% was added dropwise to react for 2 hours and aged for 10 hours to obtain nano-nickel-mol...

Embodiment 3

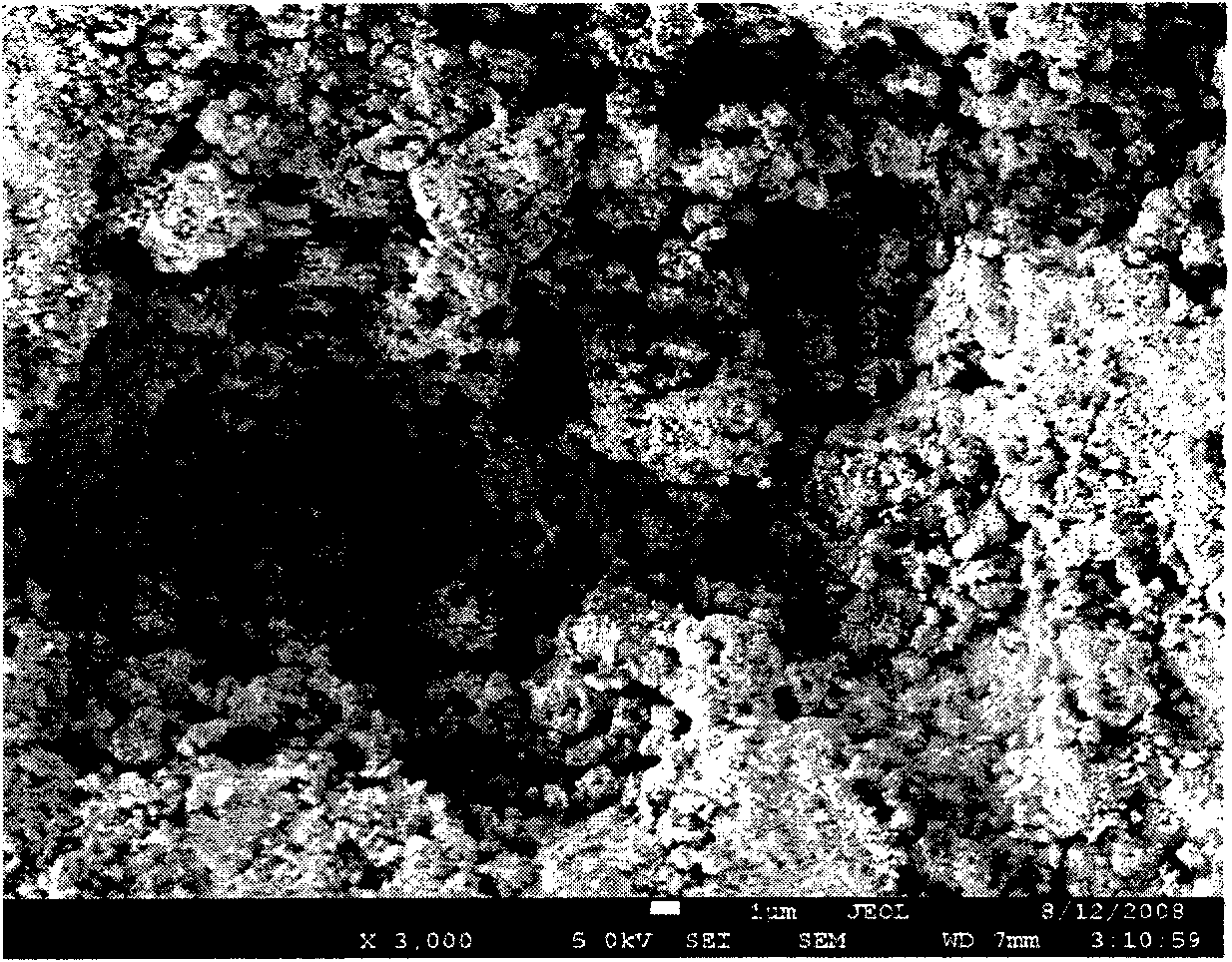

[0085] Mix 90g minus three-line dewaxed oil and 70g SP-80, heat to dissolve at 80°C, and mix well; heat 620g of aluminum nitrate nonahydrate to 80°C to melt, slowly add to the above mixture, and mix for 20 minutes to form a uniform supersolubilized colloid. 220 g of saturated ammonia water at 20° C. was added dropwise and aged for 3 hours to obtain a nano-aluminum hydroxide gel. Wash three times with 200ml of distilled water, and dry at 120°C for 10 hours to obtain dried nanometer aluminum hydroxide gel powder.

[0086] Heat 265g of common three-line oil, 35g of minus three-line wax paste, 80g of polyisobutenyl diethylene glycol maleate, and 20g of tall oil amide at 120°C to dissolve and mix evenly; mix 208g of urea and 290g of nickel nitrate and heat to 120°C to melt , added dropwise to the above mixture, and mixed for 20 minutes to form a uniform supersolubilized micelle. Close the reactor, react at 120°C for 4 hours, wash with distilled water for 3 times, and then dry at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com