Low-cost method for synthesizing ZnxCd1-xSe (x is more than or equal to zero and less than or equal to 1) and related core/shell structured semiconductor nanocrystals thereof

A synthesis method and nanocrystal technology, applied in chemical instruments and methods, selenium/tellurium compounds, inorganic chemistry, etc., can solve the problems of complex nanocrystal process, high synthesis cost, harsh reaction conditions, etc. The effect of preparation cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

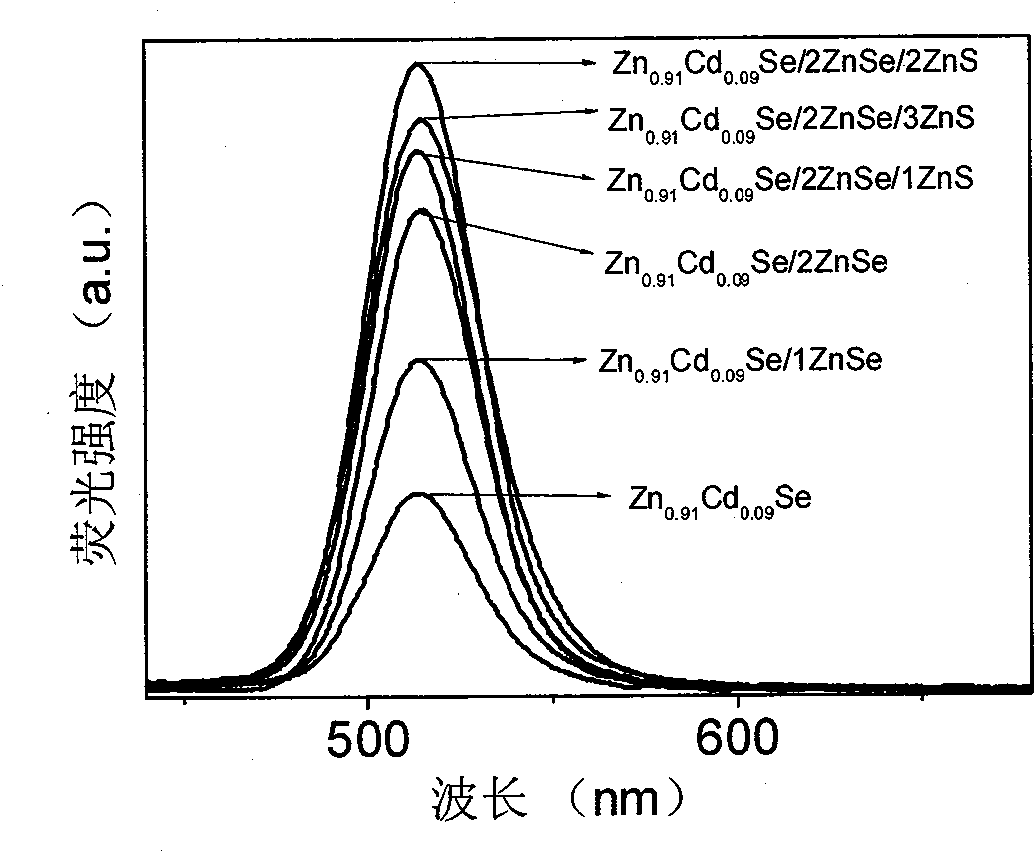

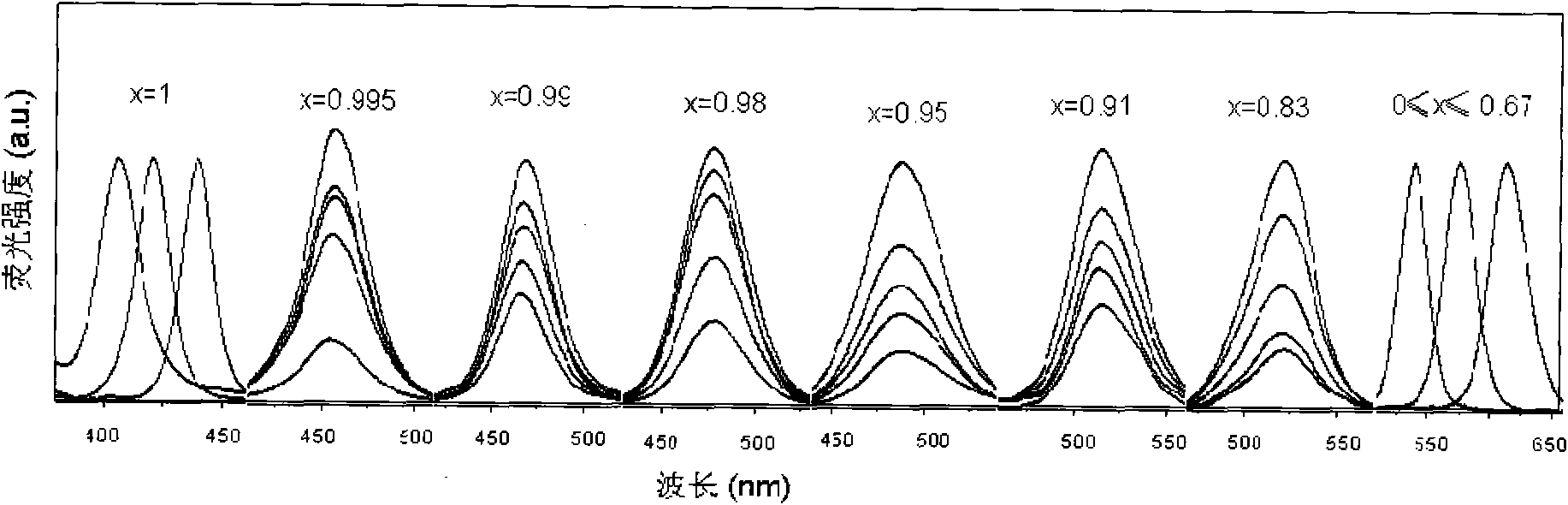

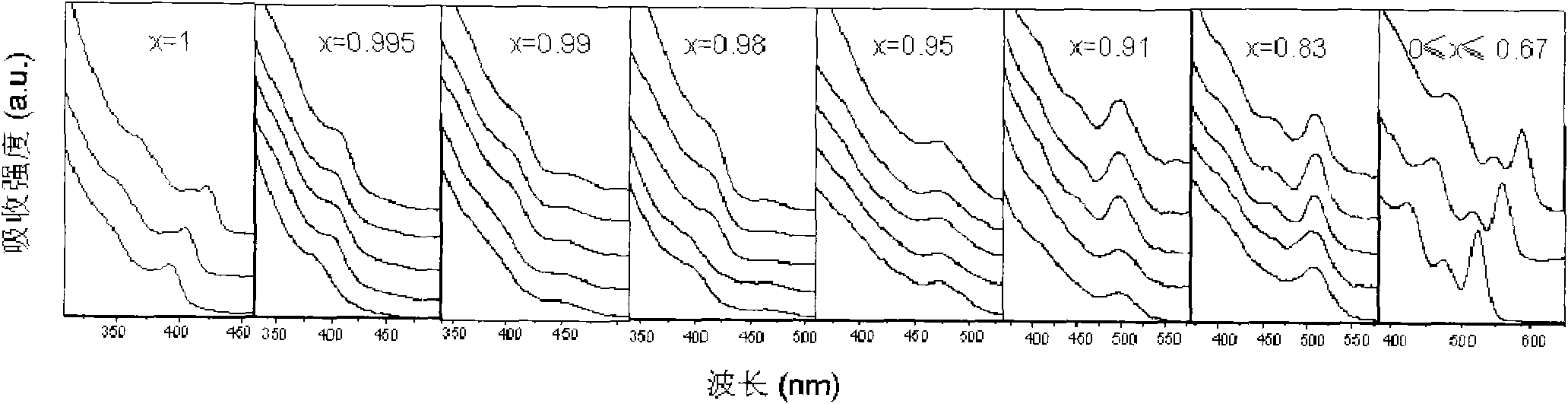

[0022] Synthesis of ZnSe (x=1) nanocrystals: Take 2mL of Se precursor solution (2mmol (0.16g) Se and 20mL of octadecene mixed into a 50mL three-neck flask, and heat at 220°C for 3 hours to obtain a light yellow Se precursor solution) and 4mL of octadecene were mixed into a 25mL three-neck bottle, and when heated to 260°C under nitrogen protection, 1mL of zinc precursor solution (2mmol (1.254g) zinc oleate dissolved in 10mL of liquid paraffin) was quickly injected into growing in the above solution and cooling down to 240° C. to obtain ZnSe nanocrystals. Take samples at 10s, 5min, and 1h to obtain the fluorescence spectrum as figure 1 (x=1), the fluorescence range is 400-450nm, the half-peak width is between 14-17nm, the quantum yield is 40-60%, and the absorption spectrum is as figure 2 (x=1), the final synthesized ZnSe nanocrystal XRD and TEM pictures are as image 3 (x=1).

Embodiment 2

[0024] Synthetic Zn 0.995 Cd 0.005 Se (x = 0.995) nanocrystals: Take 2mL Se precursor solution (2mmol (0.16g) Se and 20mL octadecene are mixed and added to a 50mL three-neck flask, and heated at 220°C for 3 hours to obtain a light yellow Se precursor solution ) and 4mL of octadecene were mixed into a 25mL three-neck flask, and when heated to 280°C under nitrogen protection, 1mL of zinc and cadmium precursor solutions (1.99mmol (1.248g) zinc oleate and 0.01mmol (respectively) (0.00674g) cadmium oleate was dissolved in 10mL liquid paraffin to obtain zinc and cadmium precursors) was injected into the above solution, and cooled to 260°C to grow to obtain Zn 0.995 Cd 0.05 Se nanocrystals. Take samples at 10s, 1min, 5min, 30min, and 1h (from bottom to top) to obtain the fluorescence spectrum as figure 1 (x=0.995), the fluorescence peak position is 456nm, the quantum yield is 55%, and the half-maximum width is 33nm, and the absorption spectrum is as follows figure 2 (x=0.995). ...

Embodiment 3

[0026] Synthetic Zn 0.99 Cd 0.01 Se (x=0.99) nanocrystals: Take 2mL of Se precursor solution (2mmol (0.16g) Se and 20mL of octadecene are mixed and added to a 50mL three-neck flask, and heated at 220°C for 3 hours to obtain a light yellow Se precursor solution ) and 4mL of octadecene were mixed into a 25mL three-neck bottle, and when heated to 300°C under nitrogen protection, 1mL of the precursor solution of zinc and cadmium (1.98mmol (1.251g) zinc stearate and 0.02mmol (0.01356 g) cadmium stearate (dissolved in 10mL liquid paraffin) is injected into the above solution, and cooled to 280 ° C to grow, that is, to obtain Zn 0.99 Cd 0.01 Se nanocrystals. Take samples at 10s, 1min, 5min, 30min, and 1h to obtain the fluorescence spectrum as figure 1 (x=0.99, from bottom to top), the fluorescence peak position is 467nm, and the quantum yield is 60%, and the width at half maximum is 35nm, and absorption spectrum is as figure 2 (x=0.99), the Zn that finally gets 0.99 Cd 0.01 S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com