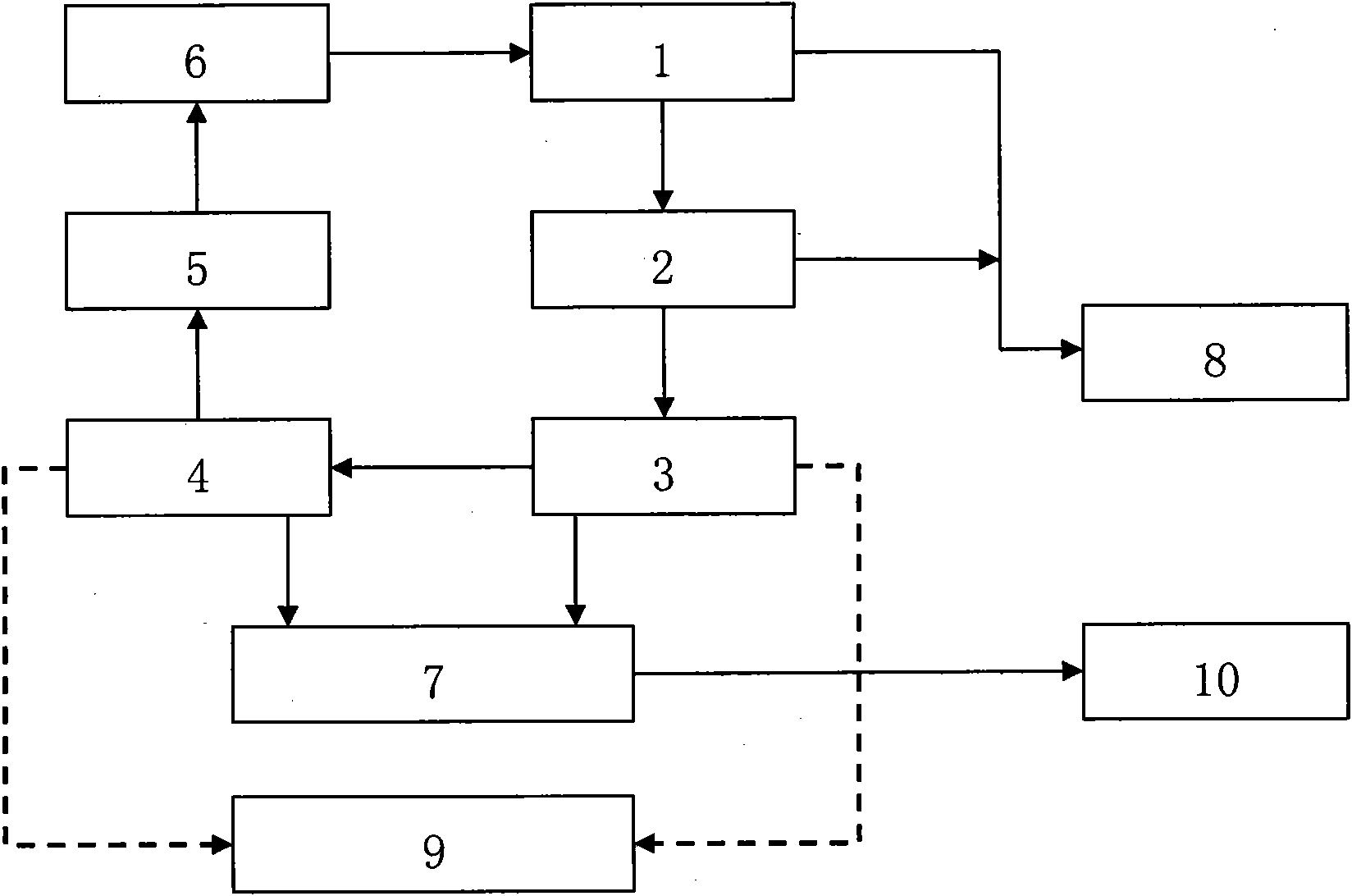

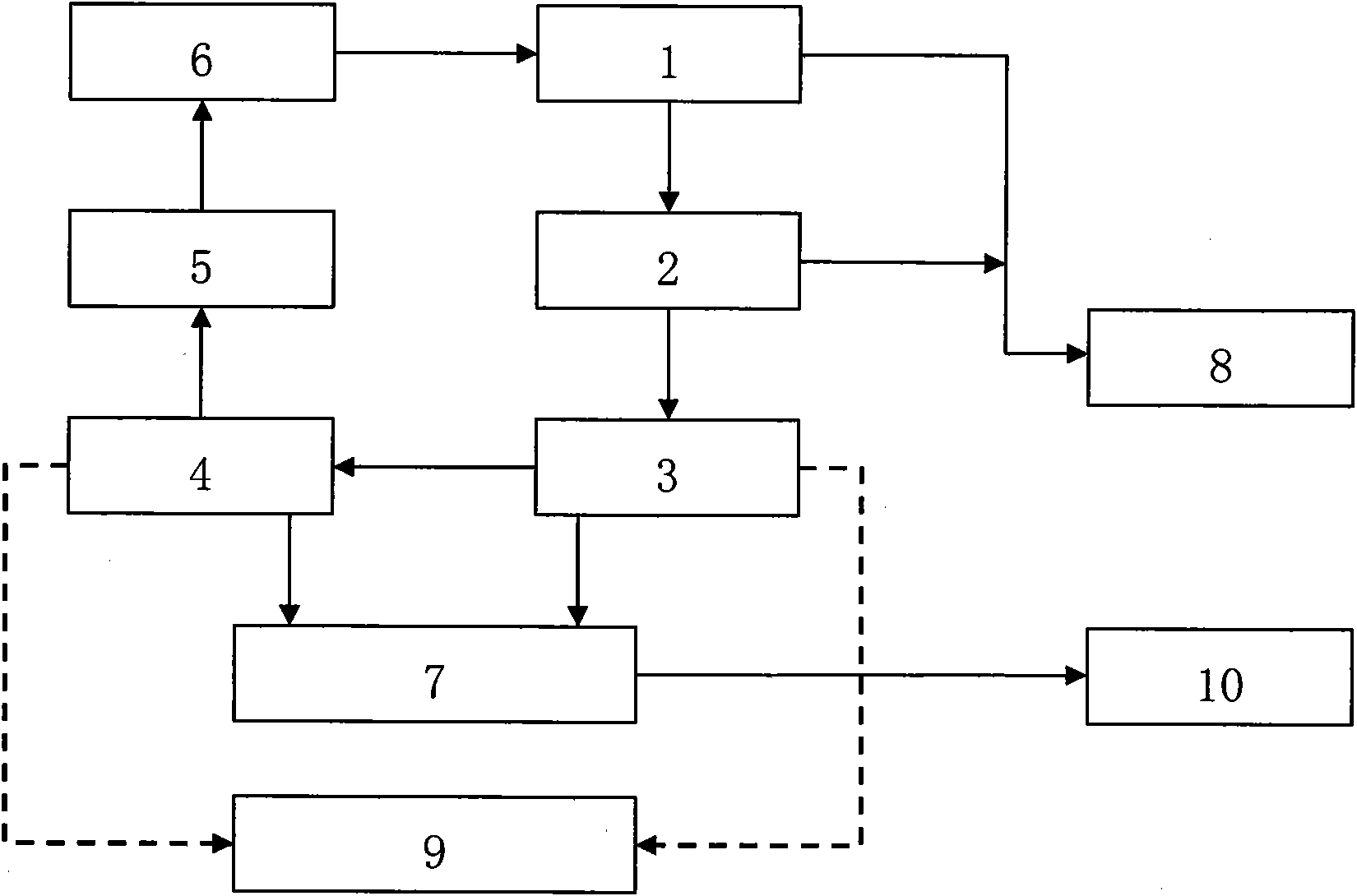

Large manual sandstone factory wastewater treatment process

A technology for artificial sand and waste water treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Low universality and other problems, to achieve the effect of reducing environmental risks and improving the construction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0013] In the wastewater treatment of the large-scale artificial gravel plant of Guanyinyan Hydropower Station, the wastewater generated during the production process of the gravel plant is first collected in a centralized manner, and the wastewater is lifted to the primary treatment structure 2 by a mud booster pump. The primary water treatment structure mainly adopts the mud purification device ZX-250 to recover particles with a particle size of 0.08-5mm in the production wastewater, and the fine sand recovery rate can reach more than 90%. The recovered fine sand is transported by the aggregate conveyor belt conveyor To the finished product sand bin 8; after the production wastewater is settled and recovered by the first-level mud purification device model ZX-250, the overflow wastewater is sent to the vertical flow sedimentation tank 3 (length×width×height=42m×21.2m×11.1m) Carry out secondary precipitation, which mainly removes particles with a particle size of ≤0.08mm in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com