Crack grouting material for blast furnace body and preparation method thereof

An iron-making blast furnace and slurry pressing technology, which is applied in the field of refractory materials to achieve the effects of good thermal stability, high thermal conductivity and small thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

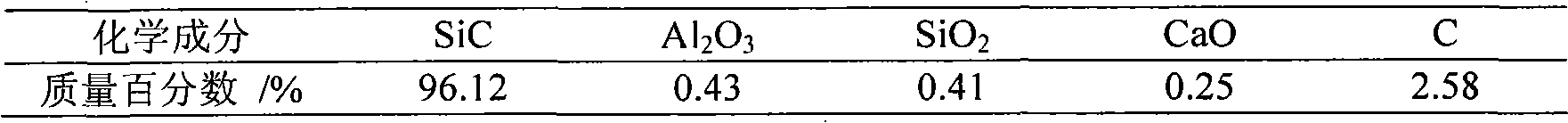

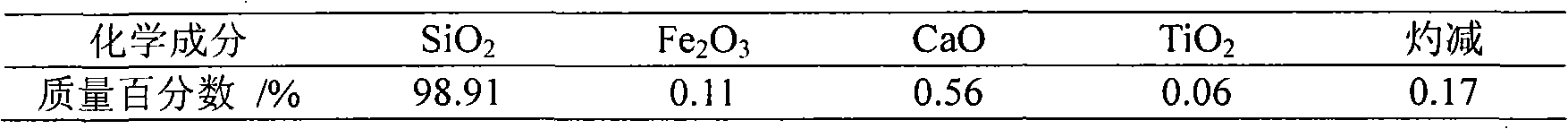

[0023] The composition of main ingredients: silicon carbide 66.31%, quartz 26.8%, alumina 5.9%, graphite 0.99%.

[0024] The add-on of binder is 52.72% of the main ingredient add-on, wherein: industrial grade polyvinylpyrrolidone (PVP) K-60 add-on is 7.27% of the main ingredient add-on, polyethylene glycol (PEG)-400 add-on is 45.45% of the main material addition.

[0025] Firstly measure silicon carbide, quartz, alumina and graphite respectively, put them into the mixer, and dry mix them for 5 minutes; then measure polyvinylpyrrolidone (PVP) K-60 and polyethylene glycol (PEG)-400 respectively and add In a blender, blend for another 60 minutes. The blast furnace body joint grout that meets the performance requirements can be obtained.

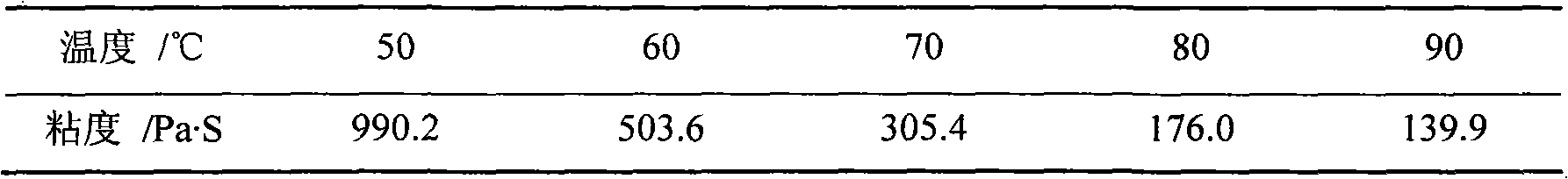

[0026] The viscosity test results of the grout at different temperatures are shown in Table 3.

[0027] Table 3 Viscosity at different temperatures

[0028]

[0029] For the grouting material, the starting temperature is 40°C, and the end...

Embodiment 2

[0033] The composition of main ingredients: silicon carbide 67.1%, quartz 26.01%, alumina 5.9%, graphite 0.99%.

[0034] The add-on of binding agent is 53.1% of the main ingredient add-on, wherein: industrial grade polyvinylpyrrolidone (PVP) K-60 add-on is 7.32% of the main ingredient add-on, polyethylene glycol (PEG)-400 add-on is 45.78% of the main material addition.

[0035] Firstly measure silicon carbide, quartz, alumina and graphite respectively, put them into the mixer, and dry mix them for 5 minutes; then measure polyvinylpyrrolidone (PVP) K-60 and polyethylene glycol (PEG)-400 respectively and add In a blender, blend for another 60 minutes. The blast furnace body joint grout that meets the performance requirements can be obtained.

[0036] The viscosity detection results of the grout at different temperatures are shown in Table 5.

[0037] Table 5 Viscosity at different temperatures

[0038]

[0039] The detection of the mass change of the press grout at differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com