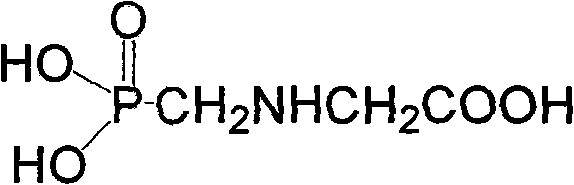

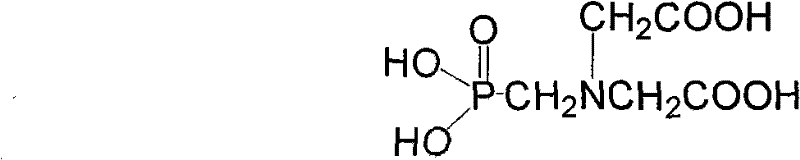

Method for preparing N-phosphonomethyliminodiacetic acid

A dipping technology of diglyphosate, which is applied in the new process field of preparing diglyphosate, achieves the effects of improving the reaction yield, overcoming a large amount of salty wastewater, and being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

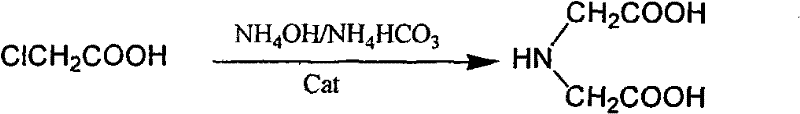

[0021] (1) Step 1: Preparation of iminodiacetic acid

[0022] Enter 30% ammoniacal liquor 56.7g (1.0mol) and 2.0g ammonium bicarbonate salt in reaction flask, then enter 0.5g catalyst CoCl After stirring, at room temperature, drop the 150ml aqueous solution of 197.0g (2.1mol) chloroacetic acid, After the addition, continue to stir at room temperature for 7 hours, then raise the temperature to above 100°C to distill the distillate, and keep it at this temperature for 5 hours. Sampling and analysis of chloroacetic acid content is less than 1.0% and free chlorine content is less than 1.0%, and the reaction solution is directly processed without treatment. One step reaction. The yield of this step is 90.5%.

[0023] (2) Step 2: Preparation of Diglyphosate (PMIDA)

[0024] Add 82.0g (1.0mol) of phosphorous acid and 156.5g (1.5mol) of hydrochloric acid (35%) to the reaction solution of the previous step, stir evenly and then raise the temperature to above 100°C and start adding 75...

Embodiment 2

[0026] (1) Step 1: Preparation of iminodiacetic acid

[0027] Enter 30% ammoniacal liquor 56.7g (1.0mol) and 2.0g bicarbonate ammonium salt in reaction flask, then enter 0.5g catalyst ZnCl After stirring, add dropwise the 150ml aqueous solution of 197.0g (2.1mol) chloroacetic acid at room temperature, After the addition, continue to stir at room temperature for 7 hours, then raise the temperature to above 100°C to distill the distillate, and keep it at this temperature for 5 hours. Sampling and analysis of chloroacetic acid content is less than 0.5% and free chlorine content is less than 1.0%, and the reaction solution is directly carried out without treatment. One step reaction. The yield of this step is 88.0%.

[0028] (2) Step 2: Preparation of Diglyphosate (PMIDA)

[0029] Add 82.0g (1.0mol) of phosphorous acid and 156.5g (1.5mol) of hydrochloric acid (35%) to the reaction solution of the previous step, stir evenly and then raise the temperature to above 100°C and start ...

Embodiment 3

[0031] (1) Step 1: Preparation of iminodiacetic acid

[0032] Enter 30% ammoniacal liquor 56.7g (1.0mol) and 2.0g ammonium carbonate in reaction flask, then enter 0.8g catalyzer ZnCl After stirring uniformly, add dropwise the 150ml aqueous solution of 197.0g (2.1mol) chloroacetic acid at room temperature, add After finishing, continue to stir at room temperature for 7 hours, then raise the temperature to above 100°C to distill the distillate, and keep at this temperature for 5 hours, take a sample and analyze the content of chloroacetic acid and free chlorine to be less than 1.0%, and proceed to the next step without any treatment reaction. The yield of this step is 85.6%.

[0033] (2) Step 2: Preparation of Diglyphosate (PMIDA)

[0034] Add 82.0g (1.0mol) of phosphorous acid and 156.5g (1.5mol) of hydrochloric acid (35%) to the reaction solution of the previous step, stir evenly and then raise the temperature to above 100°C and start adding 75.0g (1.0mol) of formaldehyde (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com