Method for extracting l-4-hydroxyisoleucine from fermentation catalytic liquid

A technology of hydroxyisoleucine and L-4-, applied in the field of separation and purification, can solve the problems of cost reduction, expensive raw materials, low extraction rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Method for extracting L-4-hydroxybiobine in fermentation catalysts comprising the steps of:

[0058] (1) L-4-hydroxyisineluminine fermentation catalytic solution was prepared by the following method:

[0059] 1 After the concentration of Escherichia coli resection of L-4-hydroxyisoleine, it is used in seed tank medium containing final concentration of 0.1 g / L amp, at 37 ° C, pH 7.0, and solubol control. Cultured in more than 25% of the OD of the bacteria 600 The value is 15 to obtain a seed liquid;

[0060] 2 The seed fluid obtained by step (1) is 10% in the fermentation tank medium according to the volume percentage of 15%, and the liquid is deeply ventilated under 36 ° C and then cooling to 32 ° C and the final concentration is 0.1 mmol / L. IPTG continues to culture until fermentation is completed, wherein the fermentation process residue is 0.05% by weight, and the oxygen is controlled after 20 ~ 35%, pH 7.0, and the amount of glucose is carbon. source;

[0061] 3 fer...

Embodiment 2

[0068] Method for extracting L-4-hydroxybiobine in fermentation catalysts comprising the steps of:

[0069] (1) L-4-hydroxyisineluminine fermentation catalytic solution was prepared by the following method:

[0070] 1 After the concentration of Escherichia coli resection of L-4-hydroxyisoleine, it is used in seed tank medium containing final concentration of 0.1 g / L amp, at 37 ° C, pH 7.0, and solubol control. Cultured in more than 25% of the OD of the bacteria 600 The value is 14 to obtain a seed liquid;

[0071] 2 The seed fluid obtained by step (1) is incorporated into the fermentor medium according to the volume percentage of 15%, and the liquid deep ventilated fermentation was cultured under 35 ° C and then cooled to 30 ° C and the final concentration was 0.1 mmol / L. IPTG continues to culture until fermentation is completed, wherein the fermentation process residue is 0.05% by weight or less, and the oxygen is controlled after 20 ~ 35%, pH 6.5, and the base glycoose is ap...

Embodiment 3

[0079] Method for extracting L-4-hydroxybiobine in fermentation catalysts comprising the steps of:

[0080] (1) L-4-hydroxyisineluminine fermentation catalytic solution was prepared by the following method:

[0081]1 After the concentration of Escherichia coli resection of L-4-hydroxyisoleine, it is used in seed tank medium containing final concentration of 0.1 g / L amp, at 37 ° C, pH 7.0, and solubol control. Cultured in more than 25% of the OD of the bacteria 600 The value is 16, resulting in a seed liquid;

[0082] 2 The seed liquid obtained by step (1) is 10% in the fermenter medium according to the volume percentage of 15%, and the liquid is deeply ventilated under 40 ° C, and then cool down to 32 ° C and the final concentration is 0.1 mmol / L. IPTG continues to culture until fermentation is completed, wherein the fermentation process residue is 0.05% or less, and the oxygen is controlled after 20 ~ 35%, pH 7.5, and the base glycoose is used as a carbon source. ;

[0083] 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

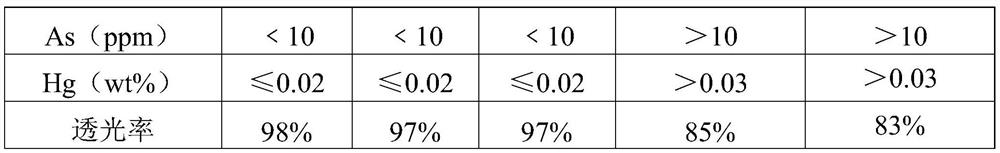

| pore size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com