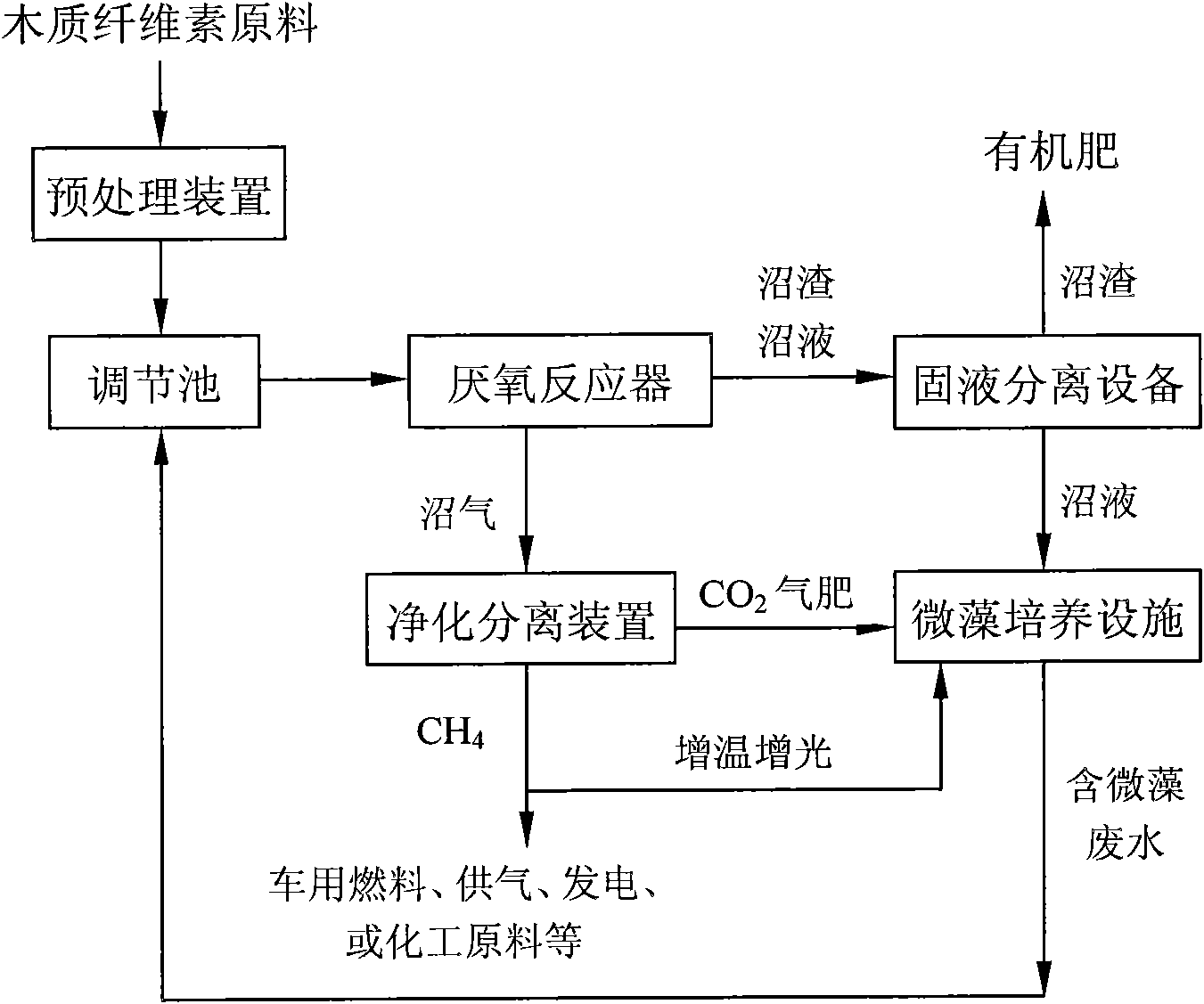

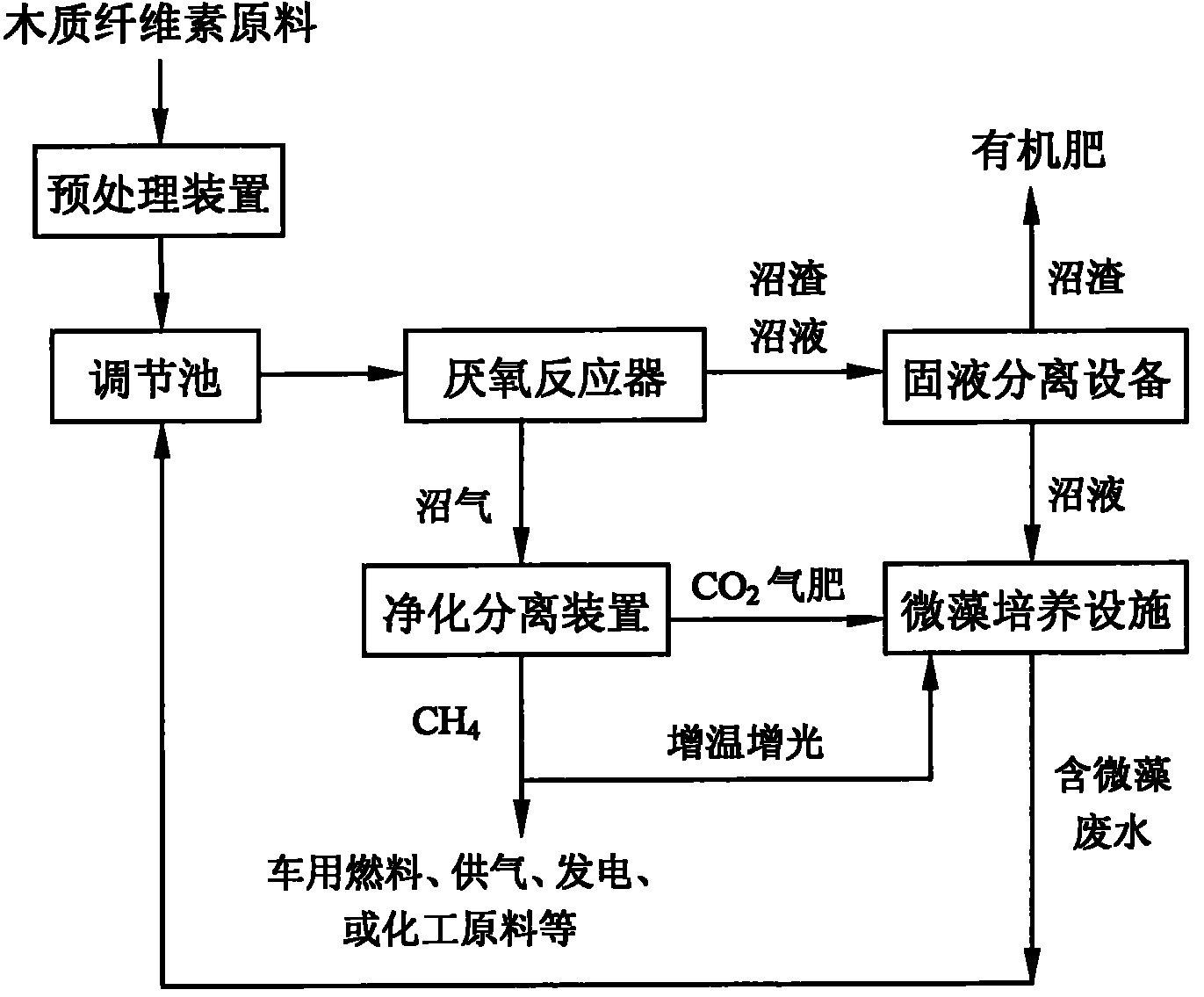

System for promoting fermentation of biogas from lignocellulose materials by utilizing microalgae

A lignocellulose and biogas fermentation technology, applied in the fields of bio-energy development and utilization and environmental protection, can solve the problems of raw material supply limitation, increase the operating cost of biogas projects, reduce economic benefits, etc., and achieve the effect of improving efficiency and energy output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] The green corn stalks harvested from the field are kneaded and cut into raw material sections with a length of 2 to 3 cm, and then ensilaged. The silage-treated corn stalks are added to the conditioning tank and mixed with the algal water mixture from the Nannochloropsis culture tank. The ratio of corn stalks, Nannochloropsis and water is C / N=25:1, VS% = 10% for deployment. After the corn stalks and Nannochloropsis were acidified for 2 days in the adjustment pool, they began to feed into the CSTR reactor. 5kgVS / (m 3 ·d) Regulating and controlling the fermentation temperature of the reactor to be 38° C., the CSTR stirrer is turned on 6 to 8 times a day, and the stirring time is 15 to 20 minutes each time. The biogas produced by fermentation adopts dry desulfurization method to remove H 2 S, and then use the pressure swing adsorption process to convert CO 2 and CH 4 for separation, the separated CO 2 It blows in from the bottom of the Nannochloropsis pool, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com