Recompression supporting method of tall side slope

A slope and tall technology, applied in excavation, climate change adaptation, construction, etc., can solve problems such as difficult cleaning, unstable footing, accidents, etc., and achieve anti-sliding force and anti-sliding moment increase, falling speed and energy Reduce and reduce the effect of safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

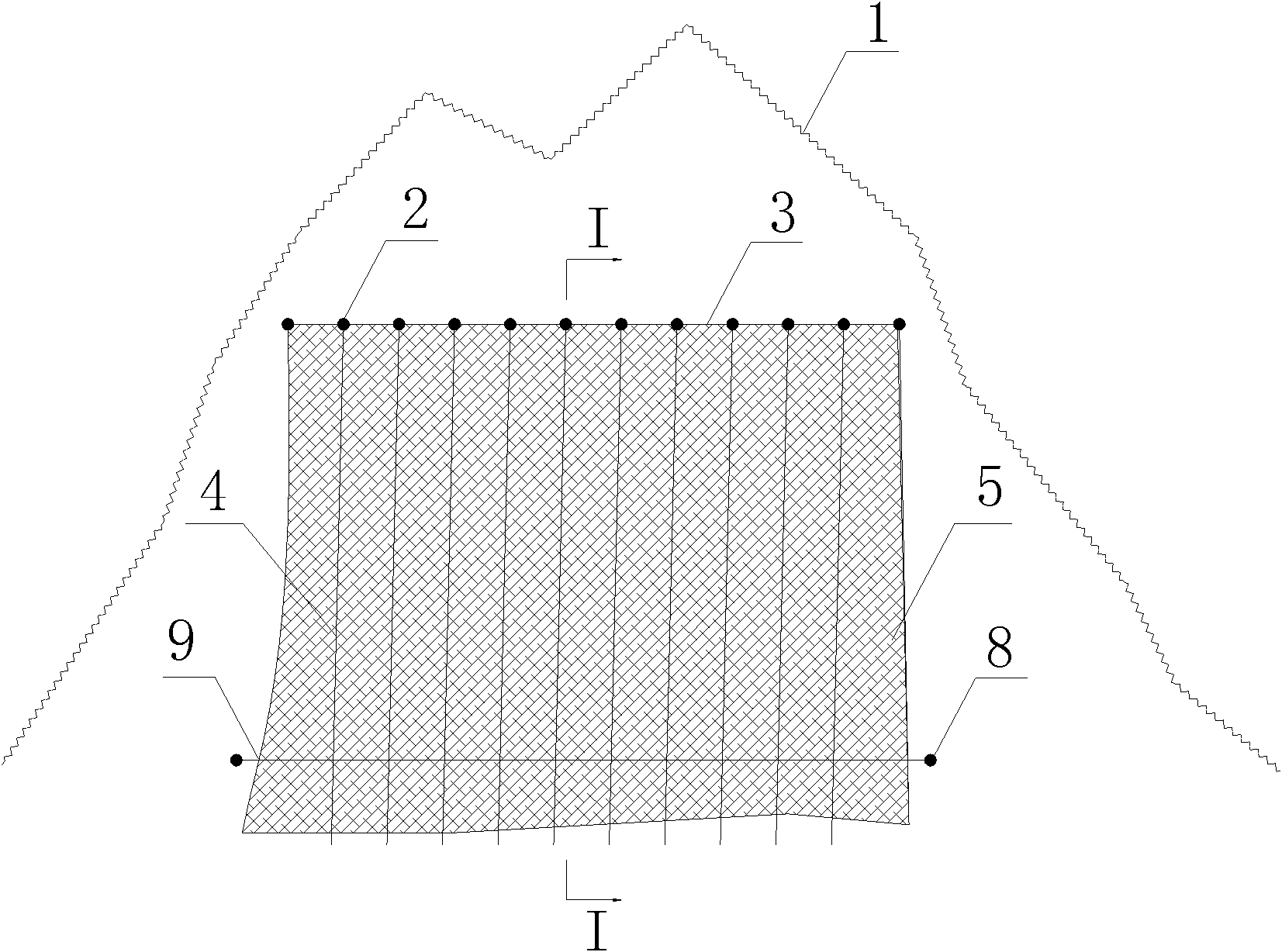

[0051] The overburden support method for tall slopes includes the following steps:

[0052] A. At a relatively open horizontal position on the top of the slope area that needs to be protected on a tall slope, drill holes at intervals of 2m to implant anchor rods, and use cement mortar 7 for grouting and anchoring. The distance between the anchor rods at the first and last ends must be greater than Equal to the width of the area to be protected, the diameter and depth of the anchor rod 2 are determined according to the working conditions;

[0053] B. Connect the anchor rod 2 with the connecting steel bar 3, and the type and quantity of the connecting steel bar 3 depend on the working conditions;

[0054] C, the geotextile 5 is fastened on the anchor rod 2 and the connecting steel bar 3, the width of the geotextile 5 is equivalent to the anchor rod 2 at both ends, and its length is greater than or equal to the height of the protected area;

[0055] D. Lay the geotextile 5 downw...

Embodiment 2

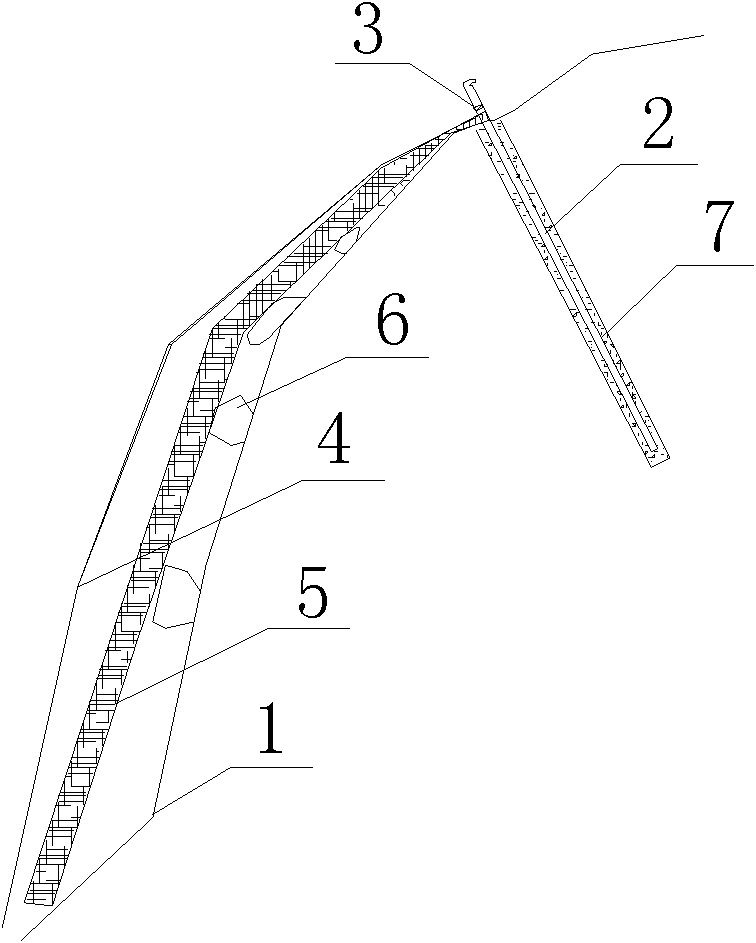

[0059] The overburden support method for tall slopes includes the following steps:

[0060] A. At a relatively open horizontal position on the top of the slope area that needs to be protected, drill holes at intervals of 5m to implant anchor rods, and use cement mortar 7 to anchor them. The distance between the anchor rods 2 at the first and last ends must be greater than or equal to the protection required The width of the bolt, the diameter and depth of the anchor rod 2 are determined according to the working conditions;

[0061] B. Connect the anchor rod 2 with the connecting steel bar 3, the variety and quantity of the connecting steel bar 3 depends on the local working conditions;

[0062] C, the geotextile 5 is fastened on the anchor rod 2 and the connecting steel bar 3, and at the same time, a pressing steel wire 4 is fastened at the top of each anchor rod 2, and the pressing steel wire 4 is on the geotextile 5, and its length is from The top of the anchor rod 2 can re...

Embodiment 3

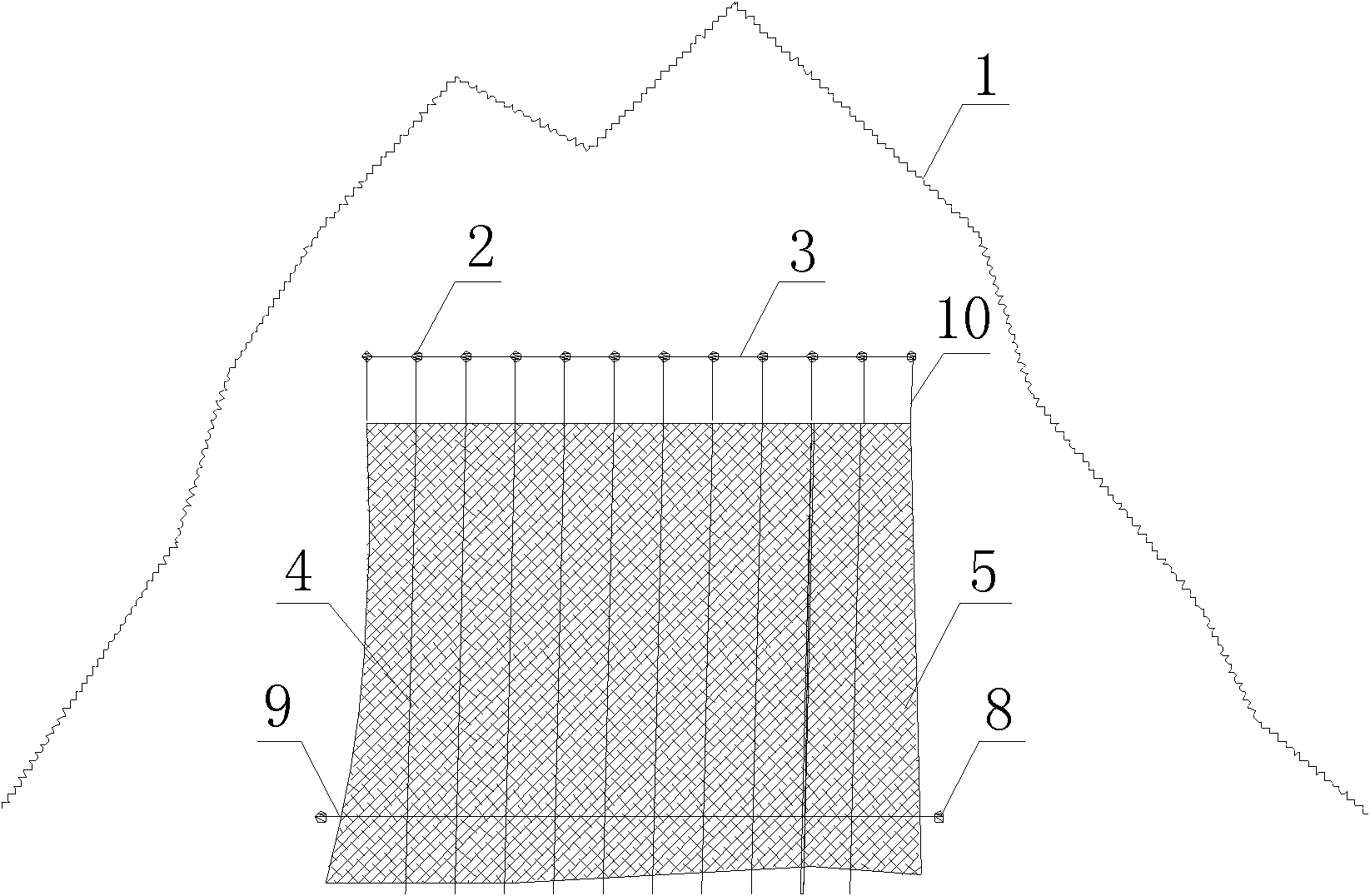

[0068] The overburden support method for tall slopes includes the following steps:

[0069] A. On the tall slope, at a position 5m higher than the top of the slope area that needs protection, drill holes to implant anchor rods 2 at intervals of 3m, and use cement mortar 7 for grouting and anchoring. The distance between the anchor rods 2 at the first and last ends must be greater than or equal to The width of the protection area, the diameter and depth of the anchor rod 2 are determined according to the working conditions;

[0070] B. Connect the anchor rod 2 with the connecting steel bar 3, and the type and quantity of the connecting steel bar 3 depend on the working conditions;

[0071] C, fasten 5m long suspension steel wires 10 on each anchor rod, fasten geotextile 5 on the suspension steel wires 10, the width of geotextile 5 is equivalent to the anchor rods 2 at both ends, and its length is greater than or equal to the area to be protected the height of;

[0072] D. Lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com