Condensation recycling method and device of unloading tail gas-naphtha

A technology for condensation recovery and oil unloading, which is applied in the petroleum industry, liquid hydrocarbon mixture recovery, etc., can solve the problems of safety hazards, large installation space, poor recovery effect, etc., and achieves obvious economic and environmental benefits and saves money. Directly draining cooling water, small change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

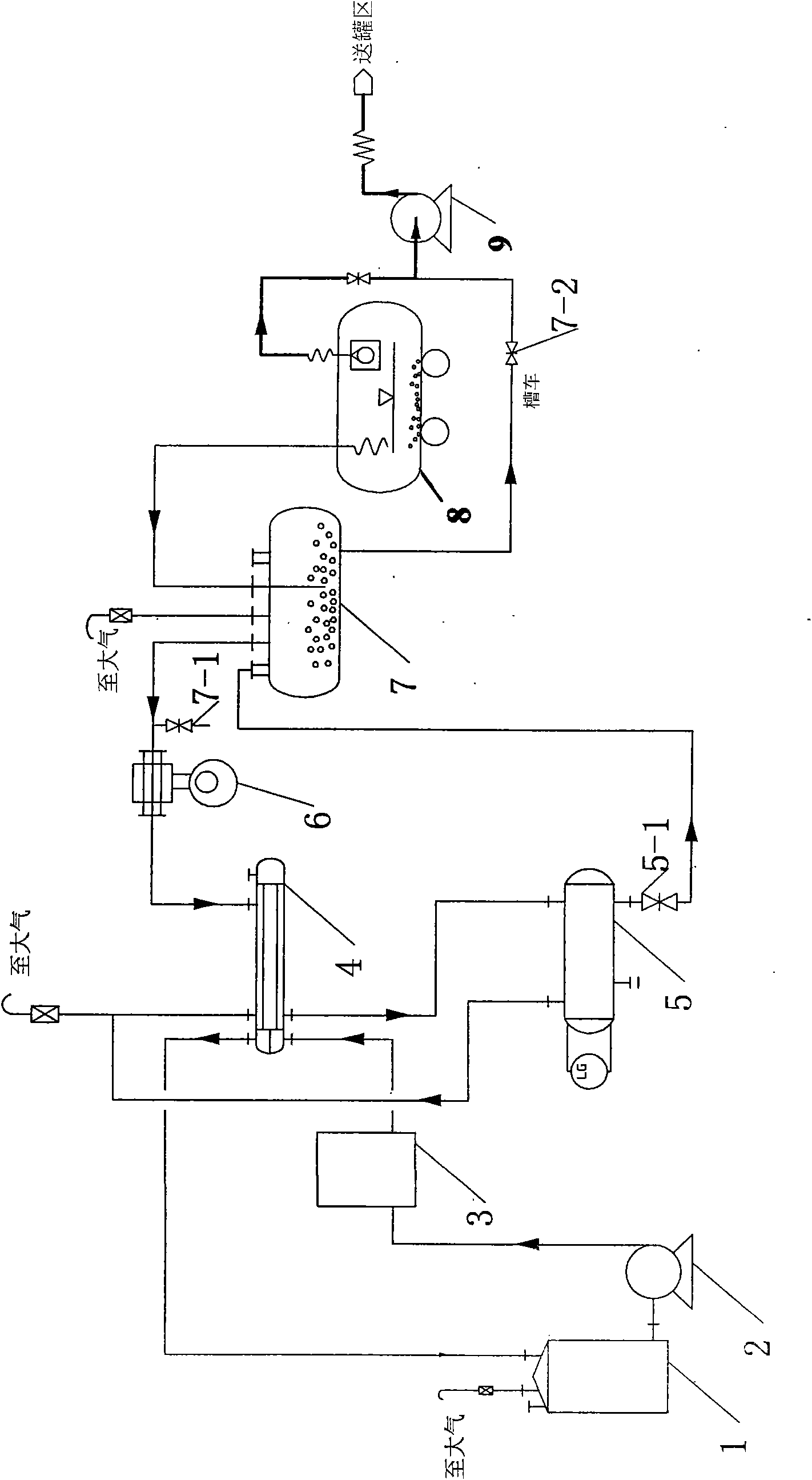

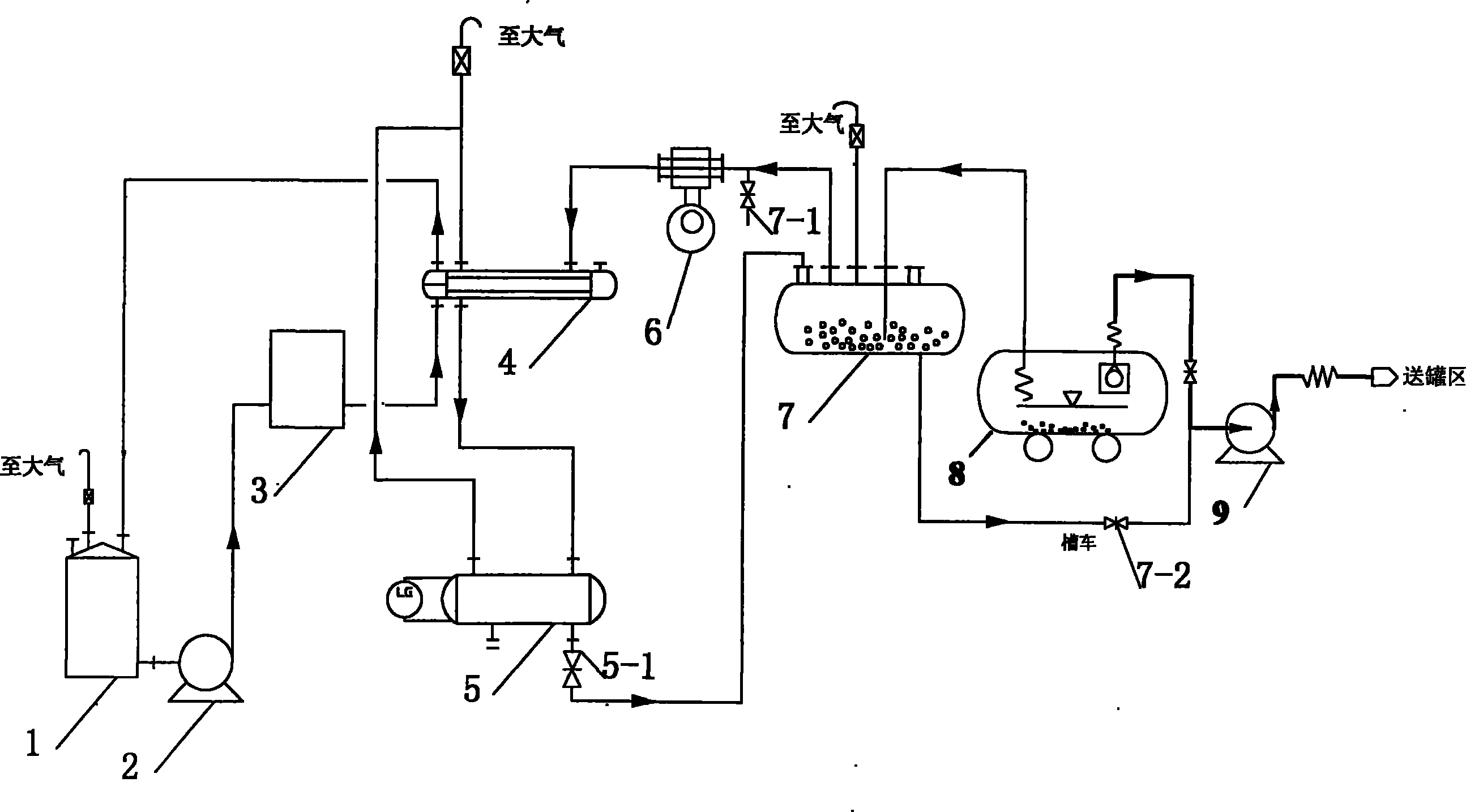

[0019] As can be seen from the accompanying drawings, the naphtha unloading tail gas condensation recovery device of the present invention mainly contains a vacuum pump 6, a vacuum tank 7, a condensate recovery tank 5, a condenser 4, and a flame arrester. There is an ice machine 3 connected through a pipeline, and the inlet of the circulation pump 2 is connected with the condensing medium ethylene glycol storage tank 1 through a pipeline to form a closed circulation system of condensing medium ethylene glycol solution, which is safe and environmentally friendly. The condensate recovery tank 5 is connected to the flame arrester through a pipeline, and the flame arrester is connected to the atmosphere, and the condensate recovery tank 5 is connected to the pipeline below the flame arrester through a pipeline, so as to prevent fire accidents caused by lightning.

Embodiment 2

[0021] As can be seen from the accompanying drawings, the naphtha unloading tail gas condensation recovery method is composed of the following steps:

[0022] (1) After the stand-alone water test run of the condensing closed-circuit circulation system is normal, add desalted water and ethylene glycol as the condensing medium to the condensing medium storage tank to prepare a ethylene glycol solution with a volume percentage concentration of 60-80%, open the inlet valve of the circulating pump, and start Circulation pump, when the outlet pressure of the circulation pump reaches 0.4-0.6MPa and is stable, slowly open the outlet valve of the circulation pump. When the outlet pressure of the ice machine is stable at 0.4-0.6MPa, the ethylene glycol solution enters the condenser from its storage tank through the ice machine , and then return to the ethylene glycol storage tank to form a closed-circuit circulation system of ethylene glycol solution; start the ice machine, the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com